I have read numerous threads on this issue and I guess I just don't understand it.

I am working on a '74 750. The engine is out of the frame and on an engine stand. Every time I go to turn the bolt to remove it the crank just turns which just prevents the bolt from loosening. How do I keep everything from turning? The other threads say to use an old axle bolt, the Honda tool looks like a socket with a T-handle on it, the Motion Pro tool looks like a bolt with a hex nut on the end. Am I missing something here?

I stopped by the local dealership today and talked with one of the mechs. Fairly old guy who according to the rest of the people in the shop said he knows these bikes inside and out. He said to stick a piece of bar through the rod wrist pin holes and hit the bolt with an impact. I am scared to do that. Afraid that something will bend or break.

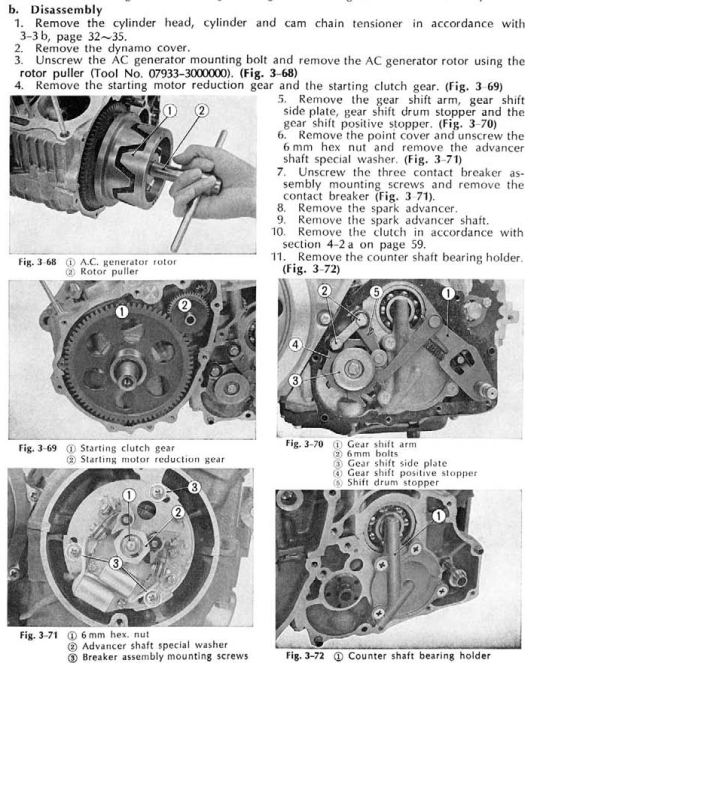

Additionally, the 6mm nut in figure 3-71 just spins as well.

Now is it necessary to remove these parts just to split the cases?