I think the results are in but my pictures did not come out

. I tore the engine down and the root cause of my low compression/oil burning was shi**y machining! First of all, as I was tearing down, I was careful to look for assembly errors by me. I did not find any. The rings were installed in correct order with the chrome on top and bevel facing up. The end gaps were still staggered just as I installed them. What I have are ring end gaps that are closer to spark plug gaps. Here are the numbers:

Ring gap spec for top and middle compression ring is .008-.016 with a limit of .0276. I did not have anything less than 0.030. Clearly out of spec.

Ring gap for oil scavengers is .004 to .012 with a limit of .0276. I did not have any less than .032 and I had several above .040. I can just hear the wind whistleing by the rings as the pistons try in vane to build compression.

The worst indicator is I can see light between the rings and cylinder walls when I shine a flashlight up from the bottom. I mean lots of light! I won't bore you with the cylinder readings but I did not have any less than 61.75mm when max should 61.60mm. I'm running 61.50 mm pistons.

I was able to score an excellent cylinder on flea bay for $60 shipped. It's a standard bore so now I need to find a shop that knows what the hell they are doing.

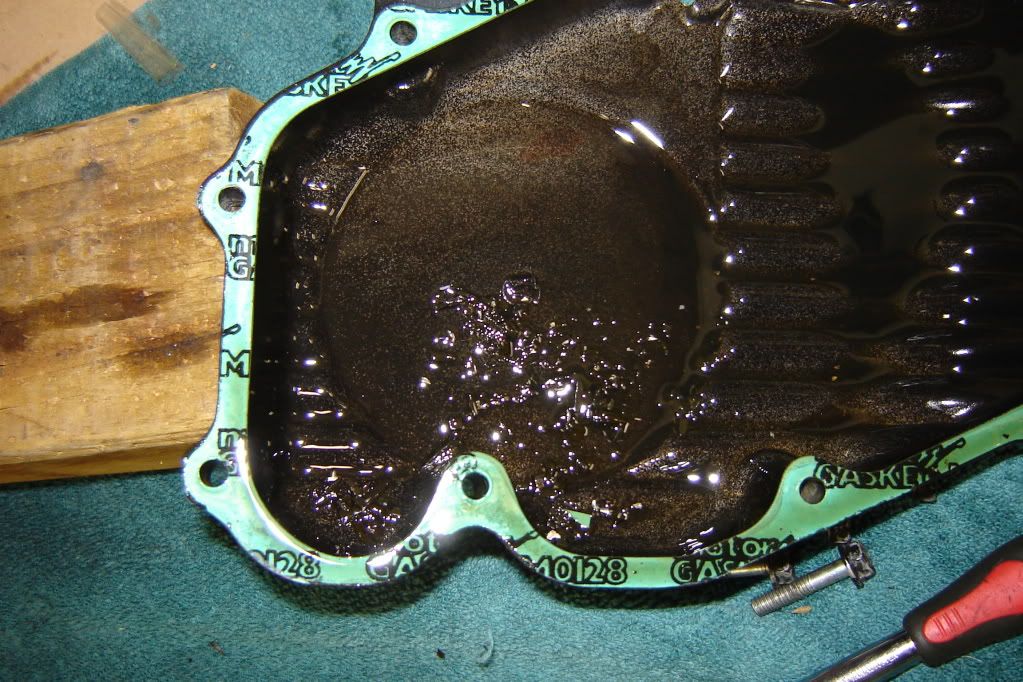

I will be doing the o ring mod to the oil pump (replacing the three o rings). Here is what I found when I pulled the pan.

The material is not metallic but crumbly, kinda of rubber stuff. I have extream wear markets on the cam tension-er idler. The cam chain really dug in so I'm suspecting that's where the material came from.

Obviously I've gone back to the machine shop for satisfaction. They measured my cylinder an agreed it is out of spec. I'm asking for the return of my $180 boring charge, $80 for a new gasket set and $60 for the cylinder from flea bay. I'll let you know.

Lesson learned: Make sure the shop has extensive experience with Honda motors