Ok, did a ton of work over the past few days.

Moving along with putting the engine together, assembling the clutch-

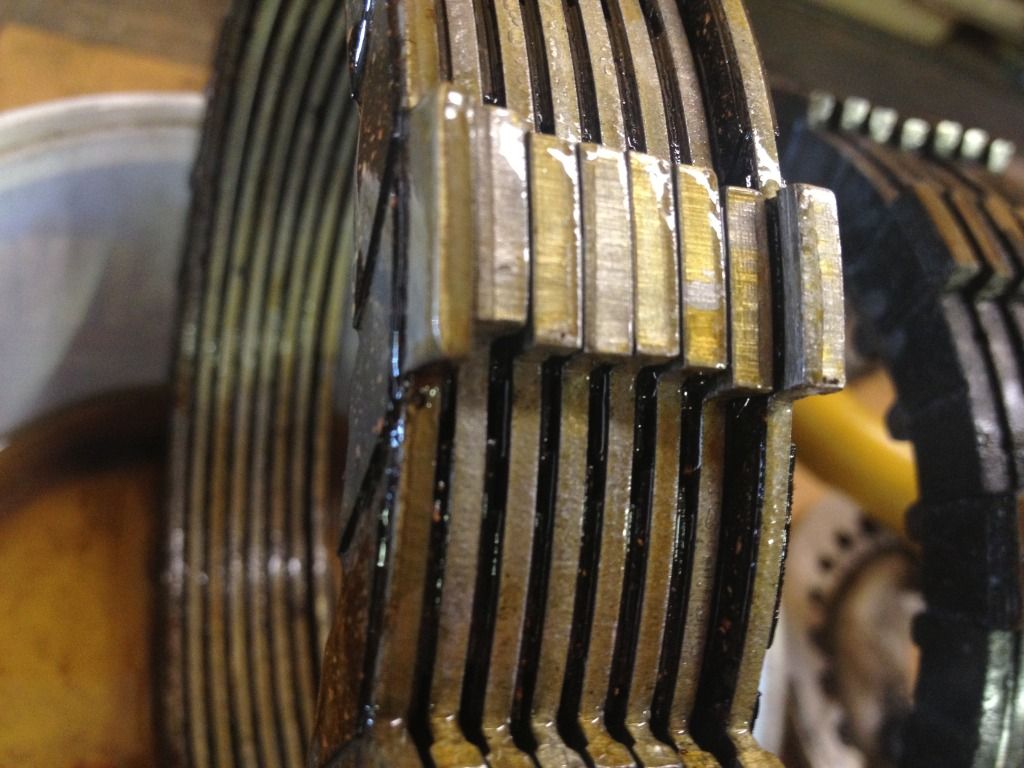

New friction discs from cycle-x

Compared to the old discs-

As you can see, one doesn't belong. I'm not sure what models use those.

Clutch packed-

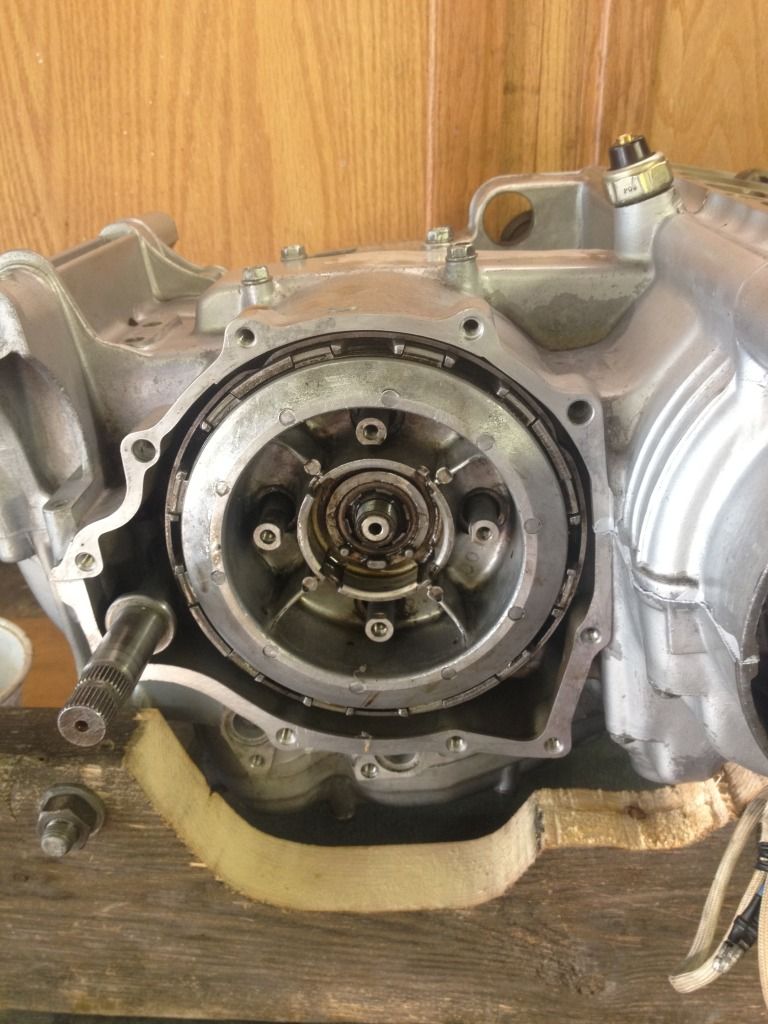

In she goes-

I had to take my tired old engine out to steal some parts-

A couple of those parts are the stator and rotor-

These are aftermarket parts for british bikes that have a permanent magnet rotor and two wire stator. Cycle-X sells them in a kit with the machined part to fit the stator in the cb750 generator cover as well as a reg/rec and wiring for it.

Covers back on-

New wiring ready-

Dropping the cylinders back on-

Had to run to the store to get a specialty tool for checking piston valve clearances-

Unfortunately my photo documentation fell by the wayside a bit over the past two days of slaving away in the 100 degree garage. I torqued down the head and left it overnight and rechecked, dropped in a webcam camshaft, and buttoned it back together-

Earlier today I finally got it back in the bike and fired it. Fortunately, it started after only two kicks. Unfortunately, the gearbox sounds like a rock tumbler with the clutch out. Tomorrow I aim to poke around at it and try to convince myself it will fix itself, or some other miracle will prevent me from having to crack the bottom end open to figure out what's going on. Aside from the rock collection in the gearbox, it seems to run OK.. but I will have to dial everything in before I get a good idea of how it's really working.

People have spoken a little about throwing a K motor in an F2 bike before but here is a good list of what's different-

-Stock F2 airbox won't bolt back in, the K carbs sit different and the mounting brackets won't match up. I don't know if a K box will fit, I don't have one.

-The intake inlets are different sizes, so you cannot just take the F2 carbs and throw them on the K motor, the rubber holders I.D. is too large the K motor intake spigots. Opposite problem if you try the F2 carbs in the K carb holders, the I.D. on the carb side is too small for the F2 carbs.

-The countershaft is about 10mm shorter. This means that, unless you set the front sprocket out about 10mm more, the chain will not be aligned with the rear sprocket.

-The throttle cables from the F2 won't work. This one caught me by surprise. The cables from the F2 are too long or the cable sheaths are too short, however you want to look at it. Subsequently, you will end up with so much throttle slack that you can twist it all the way around and it won't begin to open the carbs.

I might remember a couple other little things tomorrow... I just remembered I forgot to check the carb to tank clearance. The K carbs sit a good deal higher than the F2 carbs. IF they hit the tank that will be a nightmare