Re-assembled the front wheel this morning, tossed on the new bars and top triple clamp, and then yanked the wiring harness. I stripped off all the old loom/wrap/tape and got it all removed from the headlight bucket so I can start figuring out how to route wires for the new harness.

MOAR PROGRESS!

Removed my "glovebox" and sprayed it in rubberized undercoating

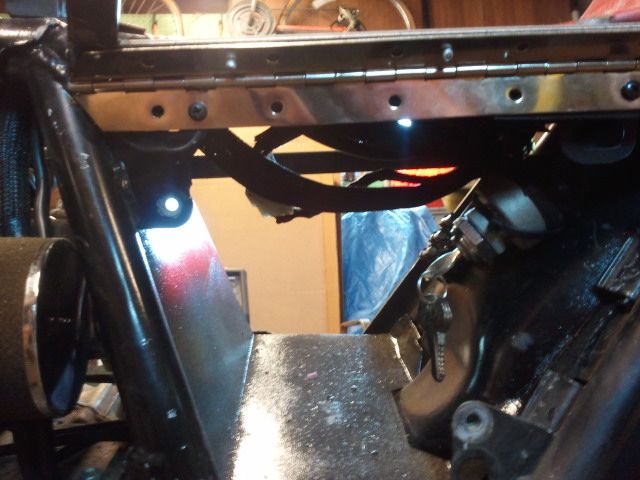

Did the same for the electronics tray after trimming in a notch for the wiring harness to pass through under the seat

Then I mounted up the new bars to test fit the new mirrors and controls

As you can see, I mounted the mirror clamped on the end of the bar, so that I can still use weighted bar ends

They clear the tank now and I have room for my hands at full lock either direction

I'm not totally sold on the bar location at this point, it might just be the fact that the fork tubes are a little over an inch too long (due to being from a CB750 and this is a CB550) making the top of the triple area looking quite bulky. I dunno, looks wierd to me. There are write-ups on how to shorten the tubes inside and shorten the springs (or just order some Progressive springs meant for the 550 and swap 'em) but I don't know if I want more down-time.

I also picked up a tap & die set and chased the buggered threads for the rear shock mounts and a few other stripped studs on the frame but pics of that would have been silly.

whats left:

-measure/order shorter throttle cables, clutch cable, and brake line from the master to the distribution block for the front brakes.

-wiring

-repair and repaint the tank

-fab mesh sidecovers

-assemble and ride!

so just when I thought I was done working on this thing for the night, I get a call from Pirite......offering to come mess with the wiring harness for a bit....how does one say no to such a thing?

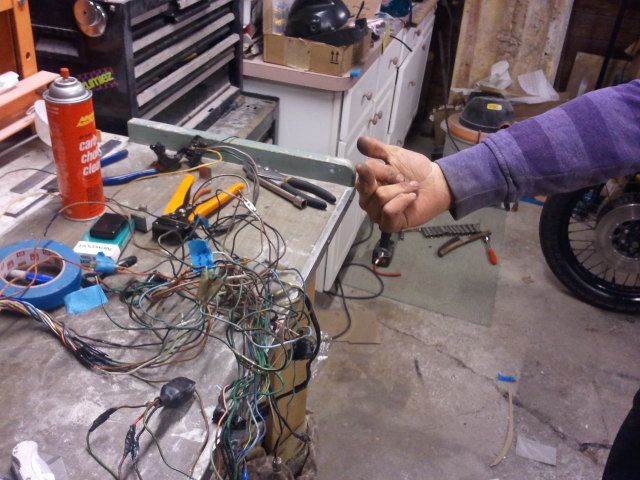

so we started trying to sort out the harnes......

"what the #$%* is this cluster#$%* of #$%*ery" -Luke (Pirite)......couldn't have said it better.

45mins later.....

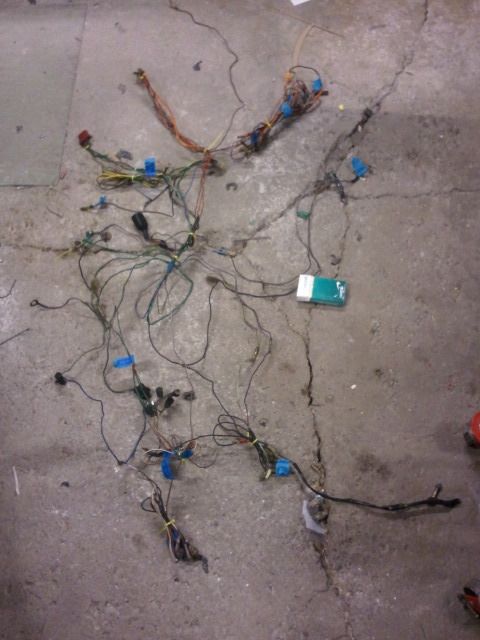

2hrs in.....got all the useless crap chopped out, and the rest bundled and tagged so we can attack it one connector at a time.

Luke stopped by again and we tag-teamed the #$%* out of the wiring and got a solid chunk of the new harness constructed. only took a handful of pics but its FAR less wires than before and the headlight bucket now has about 80% less wires in it.

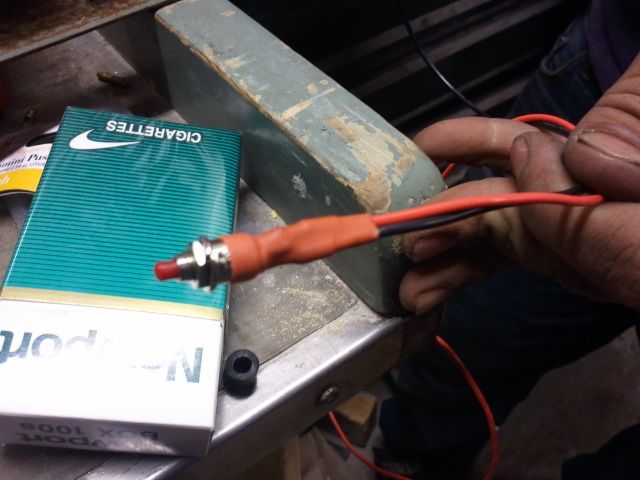

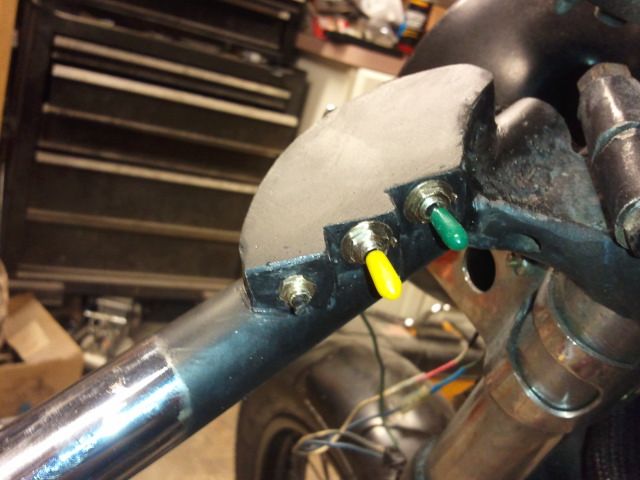

Some mini-switch setup

bucket, now with 80% MOAR LESS WIREZZZZZZZ

MOAR WIRING!

first off, shoutout to Pirite.....HUGE thanks for the many hours of skilled help here.

tackled a bunch more. the harness is not like 90% done. all that is left is a couple grounds and the headlight switch wiring.

how small my new switches are (still have to make some type of housing to hold switches...)

AND, this is what has been REMOVED:

will probably take a breather and get back at the wiring next week. Just got the estimate back from MotionPro, and my cables are going to run me $110 + shipping. WAH

Not a huge update, but I replaced the horn (old one stopped working) and JB-welded the seam of the tanks where it was weeping a little leak that was driving me nuts.

I can't seem to find some nice looming material locally to put my new harness in.....I hate that black corrugated plastic #$%* they sell at all of the parts stores.

I remember seeing a few times a mesh fabric-like material that you folded over the wires and just taped the ends......is that available locally that anyone knows of? I'm about 90% done with wiring, once this tank is finished up and painted its practically ready to ride. Just have to fab up some kind of switch mounts for the bars.

Well, progress has slowed down, mostly because the wiring is playing some tricks on us. Had to quit wiring until I can borrow the clymer manual from Checko as it has the wiring schematics in it and I need to double check some of my wires.....

I sanded down the JB Weld on the tank and sprayed it in etching primer. Just have to do some body filler on it now and then that'll be ready for paint. Just have to build side covers, build switch panels for the new switches up on the bars, and finish wiring.

I've been pretty aggravated working on it lately.....the wiring is going exactly the way I didnt want it to.....a pain in the ass with #$%* not making sense to me. Really feeling worried that I might not get it finished in time to ride down to Vintage Motorcycle days.....I didnt want to be turning the last bolt the week I'm supposed to put 600miles on it

Well beleive it or not, I finished wiring before I ran out of swear words!

got everything loomed up nice, just have to build housings for the switches up on the bars and finish the tank.....oh, and order $200 worth of cables and steel braided brake lines.

found out you can get the PAINLESS wiring mesh loom from K-S Auto on River rd. so I took a trip and got a bunch, looks awesome and is super nice to work with for maybe 20% more invested over that #$%*ty corrugated plastic bull#$%* you can get at autozone and the like

probably going to finish the tank and build the bar controls sometime over the next week, hope to be riding by next weekend if I can get the tank painted in time.

mocked it up back together for the most part.....decently pleased with the results, need to finish bodywork on the tank and make switch housings and side covers. Might get through all that this week MAYBE.

Got the key/ignition switch and the fuses mounted inside the "glove box", just have to get the wires that run just under the seat tucked up somehow and I'll be ok with that setup

OK, so I think I've got ideas for the switch housings that I won't completely hate.

for the right hand side, I think I'm just going to mimic the shape of the brake master cylinder as if it's being extended, and mount the switches into it. If you look at the pitures from when I was fabbing the round housing, you can see the squarish shape of the master, I'll just "extrude" that shape and have a little tab sneak between the part that clamps onto the bar to hold the housing.

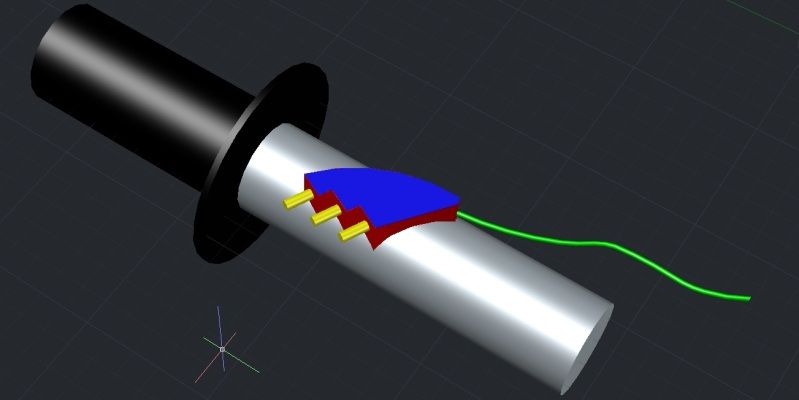

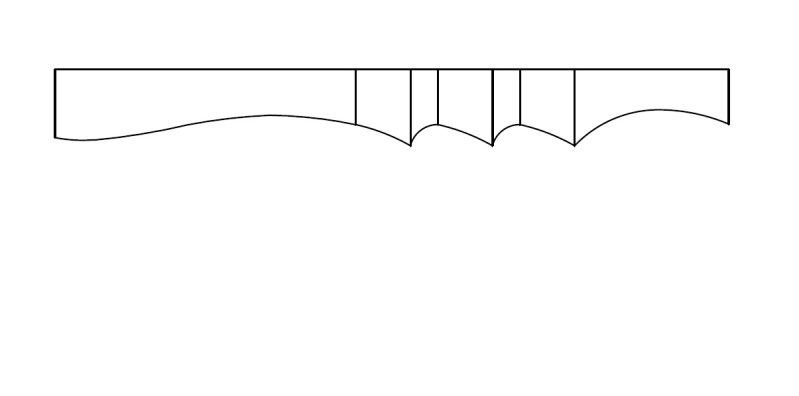

for the left side, I think this is the only non-bulky non-stupid way I can make a switch housing. It's going to be sort of a pain in the ass to make, but it ends up setting up the switches all aiming towards my thumb so it should be comfortable to use, and it should look like part of the bar when it's done. This will get the backsides of each switch aiming towards the point of exit for the wires, so I won't have as much clearance issues like I did trying to cram the wires inside that round housing I made that is now useless. In this rendering, I didnt make the clutch lever because that would have taken longer than this whole 3D image took to build in CAD.

the black is the grip, the silver is the bar.

The red would be one continuous strip of 22g steel I have kicking around that I can bend the "steps" into and the blue would be a "cap" I'd make to go over the red peice once it's welded onto the bar and blended it with some files to make it all look one piece. The green would be the wiring loom coming out of the housing.

Took my 3D housing and translated into a template to cut out.

Printed it out at 1:1, I think I'll have to revise it a bit because looking at it on paper the backsides of the switches might have a wider bas than the 1/2" I made the "steps" at for them to mount into.

Switch panels are compeleted, and I am OK with how they have turned out.

Template I made from CAD was very close, but needed some massaging once I cut it out and bent it up.....here's the process:

mocked up switches

after I made the side and front, I made a cap. I left the bottom open so I can install and remove the switches as needed.

ground it all down smooth and painted black

Other side was much simpler

made a box chanel with a flange out of one peice bent around

capped it off, ground smooth, painted black

What's left to do:

-Make side covers

-paint tank

-replace start button that I ruined by being a Tard

-swap power and ground wires on signals, wired them backwards by mistake and they don't blink (LED's are directional unlike incandescent bulbs)

Got the exhaust back on, grips back on, mirrors back on, seat permanently mounted, and connected all the stock cables......

I really wanted to get shorter cables and brake hoses on, but the cables are custom order and $150 for the three cables I need, and they probably won't make it here in time for Vintage Motorcycle Days even if I order them at this point.

Tank is in sealer, ready for paint. Probably going to take it over to my parents house and paint it this weekend because my stepdad has a mini-paintbooth in the basement from when he was building his airplane.

I might jump on making the frames for the sidecovers, replace the start button, and swap the signal wires tonight if I can find some motivation.....

Made the sidecover frames yesterday....

I used a piano hinge on the left side so I can open it up and use the storage space

But then I started running through some of the electrics....and new problem. No spark, regardless of the position I have the kill switch in....fantastic. I #$%*ing hate wiring!

Gotta get some help from my friend Pirite again, have to track this down ASAP. 38 days 'til Vintage Motorcycle Days. I'm getting super nervous the bike won't make it...