Thanks for the compliments on the CAD work!

I did get all but one exhaust bolt out, I broke the first on and that's why I went to get the right tool instead of rushing.

The swingarm will be made of steel, due to my fabrication skills and the fact that I want to trust it. I have made lots of aluminum stuff, but when my ass is riding on it I want it to be steel.

Got some suspension work done today (finally), it's the front end!

One more operation on the lathe and i'll be done, ran out of time before class though

Monday I guess.

This is how you remove the stem from your CB750 lower triple...

You get out your grinder, and take a little at a time till the grease starts to seep through, revealing the edge. I would suggest a flap-disc for this, but I did it with a cut-off wheel (all careful like). A little tapping with a BFH and it slid out easy.

Don't be too scared cause if you eff up or change your mind just replace it and re-weld it. I wouldn't recommend doing this too many times...

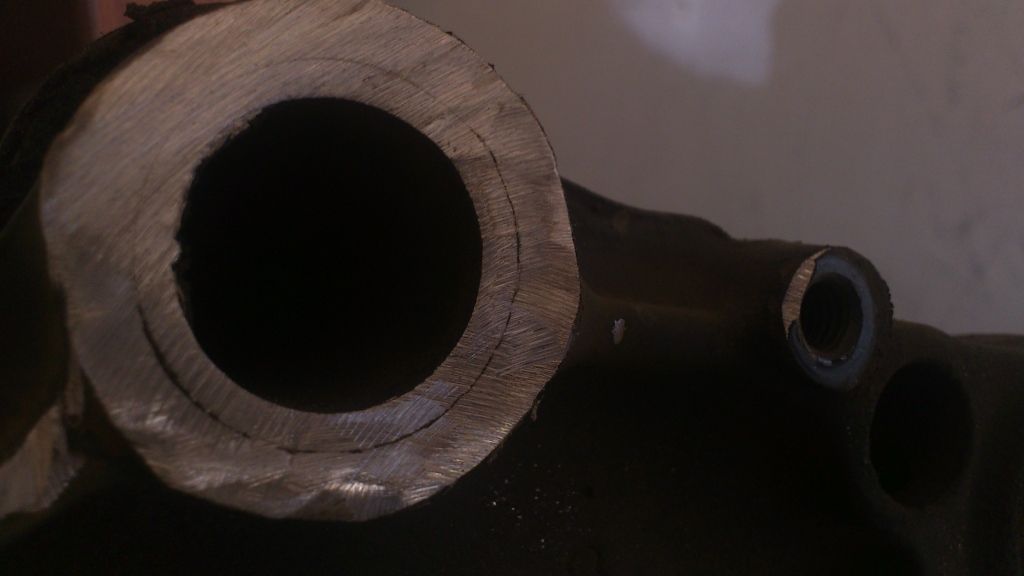

Showing how much was ground off

I bored a sleeve to fit over the stem, which will extend it and act as the stop at the bottom, while increasing the diameter to fit in the kawi lower triple

then i centre drilled three holes and welded them in place. This way i can drill it out later, and any weld can be machined off. The other advantage to this is that the lower race will be machined relative to the shaft, thus very straight despite any fitment issues prior/post weld. It was a slip-press fit as is, but insurance is nice.

The top triple was ***VERY CAREFULLY*** setup in the mill, indexed with a dial indicator, then bored with an indexing head. This took a long time, but it's not something you want to mess up.

If the alignment of the hole is out a .001" at the top, it would be about .004-.005 at the bottom, which is a pretty significant amount.

If out fore-aft it may have a little influence on rake = NBD

If out right-left then there will be issues with axle alignment, brake fitment, shocks lining up...

I spent 15min with the dial indicator making sure it was out less than 1/4 thou

Finally what's left, this needs to be turned down to fit in the kawi lower, and a shoulder will be placed so that when it inserts from the bottom all the bearing preload will be applied against it. The kawasaki part is aluminum press fit with a steel ring/clip thing at the bottom, this should work equally well, if not better.

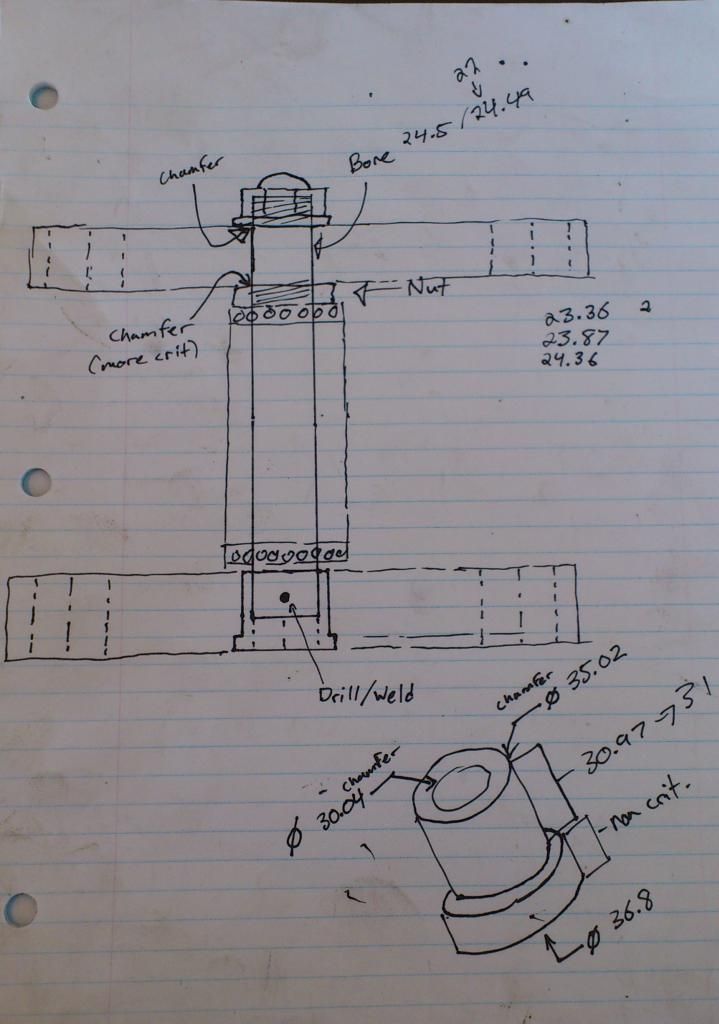

Here's my on the fly sketches of what's going on.

It's important to note that no matter how good you/your tools are you should always do the final pass by fitment.

Everything in this arrangement is slide->press fit so you're dealing with tolerances of +/- .0005 or less. Always heck before you make your last cut and don't trust your measuring tools for final fitment. My $.02