I finally made some significant progress on my re-assembly detail.

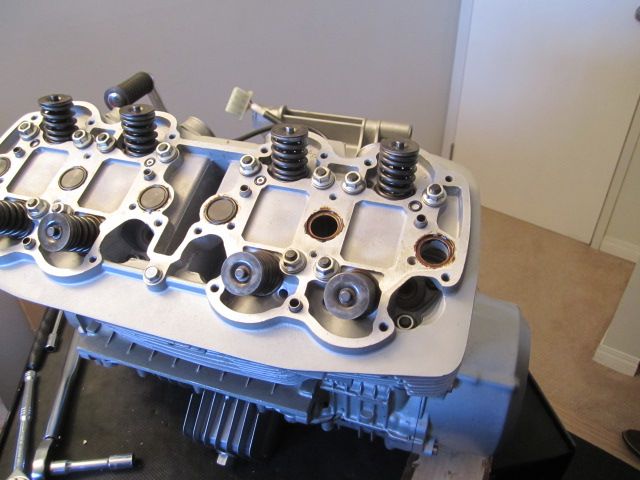

Valves installed with the new spring compressor (worked great actually). New valve guide seals just in case. Also, I've gone back to the stock springs since I sold off my CX-1 cam with HD springs to BPellerine from this forum.

Laying out all the bits to the gasket kit. One thing I did notice was you don't get new sleeve o-rings so I had to re-use mine. Fortunately mine were still nice and pliable so I don't think it will be a problem.

I had my cousin over to help me battle the cylinders back on. Made some wood spacers to hold the 2-3 pistons up and just used some popsicle sticks to depress the rings where needed. I also used a fairly liberal amount of oil on the cylinder walls this time which seems to help. We seemed to struggle a bit when we got to the 1-4 pistons because they wanted to go in cock-eyed. Tapping the top of the them with the wooden end of a hammer handle seemed to help get them back in line and it went on the rest of the way. Crank rotation was nice and smooth as you'd expect so no issues there.

New MLS head gasket (and new base gasket too with new o-rings on the oil inlet studs. One difference with the MLS gasket is you don't need to use the 8 packing rubbers or the metal dowels that go with them (so says Ken at CycleX ... lol).

Un-used dowels.

Got the head on easily enough and torqued. I went to 18ft*lb since I have the ape studs.

The shop manual is a great asset here.

Installed the cam tower pucks with a bit of form-a-gasket.

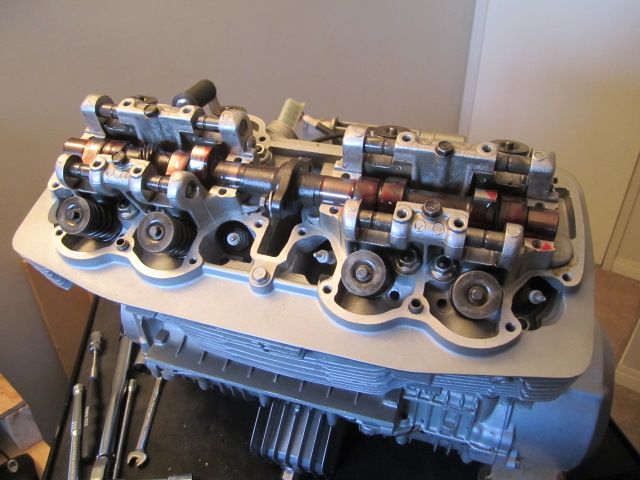

Threw the towers on and the cam before I realized we'd need the sprocket and chain on there first. lol

We got to basically this point and then the last cam tower bolt that I was torquing stripped out ... arg. So, we tore it all down again and thankfully I had the M6x1 helicoil kit and we repaired 4 cam tower bolt holes. I also had to do a bit of fixing on one of the cam bearing stud nuts as well. While I was at it I added some form-a-gasket to the lower threads of the cam bearing cap studs since they are through holes and could potentially be a leak point.

I set the lash to stock specs (.002" intake & .003" exhaust) and here we are!

Glamour shot!

One other thing I found was when putting in the oil jet one of them didn't want to seat down all the way. On inspection, I found the port to be full of bead blasting grit! I did clean the head quite well when I got it back but just goes to show you can't be too careful with that stuff. I cleaned it out as best I could with q tips and sprayed WD-40 down the passage so I think it should all be good. I'm pretty sure I could have burned up the one side of my cam if I'd left it.

IW

IW