So you'd think having 10 days or so off over xmas would mean I would get LOTS done on the bike. Nope. Not so. Spent 4 days with the gf's family, 3 days with my family, a day celebrating the new year and a day regretting said celebration...

Here is what I got done (not much):

I found this piece sitting out ... what is it?!

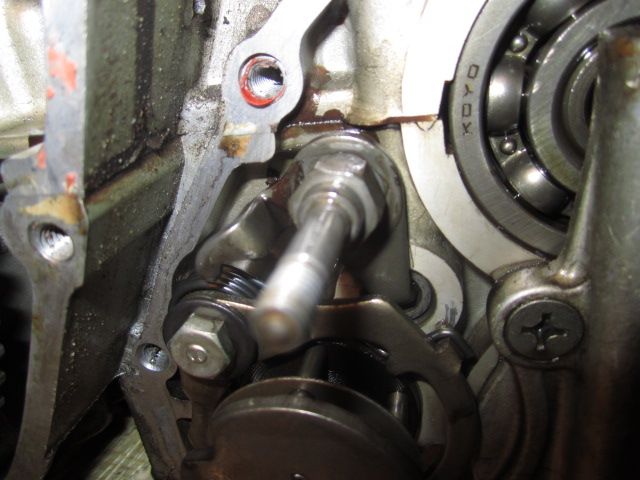

Is there a trick to getting the starter out? Mine will rock back and forth about 1/8" but won't come out.... halp!?

Got the alternator cover off.

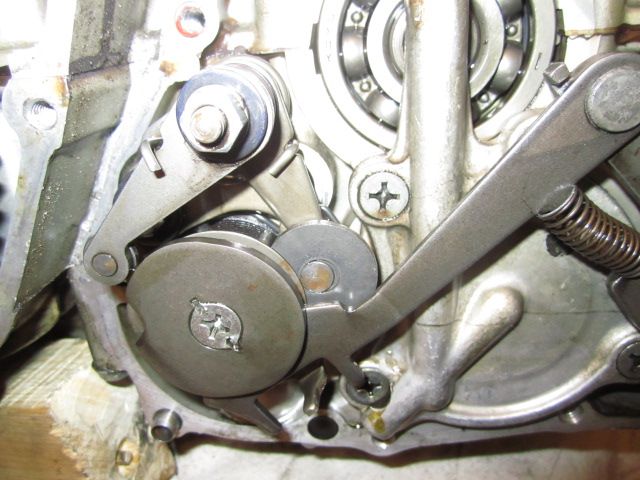

Reference pics of the shifter mechanism.

I hope I can remember all this!

Startin to come apart.

Pulled the pan off.... apparently I didn't get all the oil out...

MESS!

Some junk in the pump screen.

Shift mech parts in the order they came out.

More parts to be bagged and tagged.

So I basically just put in a couple hours tonight ... the night before I head back to work. Hopefully next weekend will be much more productive. I hope to build my crate so I can ship my head/cylinders/crank off to CycleX. I also need to find a machine shop that can pull that stud out and possibly measure my main bearings. Hopefully I can also split the cases this weekend.

Here is to high hopes for next weekend. ha

IW