So hopefully this time I can put a coherent post together without deleting all my pictures from photobucket and the thread itself...

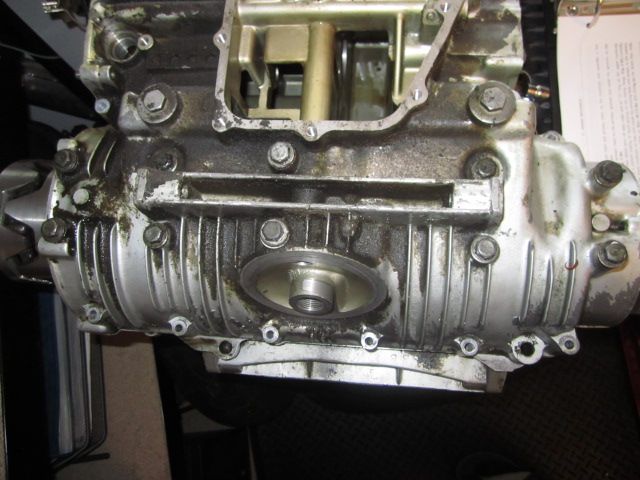

I saturday I started tearing into the cases ... nervous to split them but here we go:

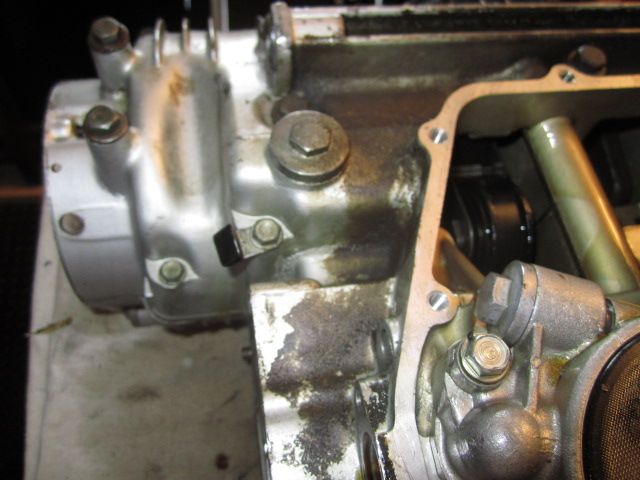

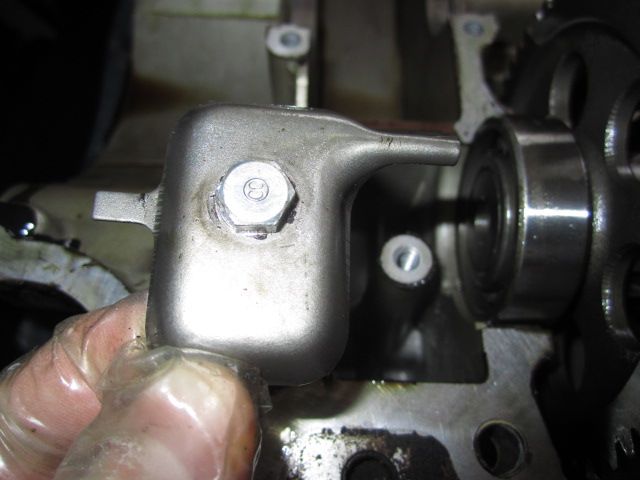

Just noting where all the various hardware and clamps and such go. This is the over flow tube holder.

Cable holder near the drive sprocket.

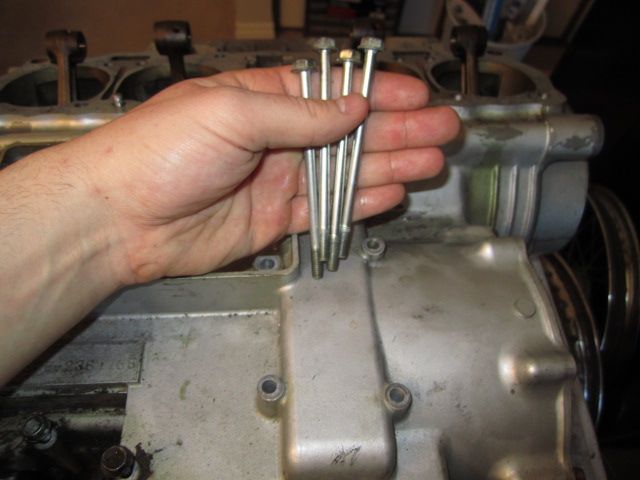

4 longest bolts go here.

Very rear right threads directly into the case.

Center rear with tube holder has a nut.

All the top side bolts...

Oh wait ... dug one out of 1/4" of grease on the left side. Also has a nut.

To the other side...

Noting the wire tabs...

4 equal length, 2 longer are on the outside ends.

Two long ones near the alternator.

All the bottom side bolts.

Neutral sensor and clamp bolt ... which allows you to remove the shift drum.

Oil pump and hardware.

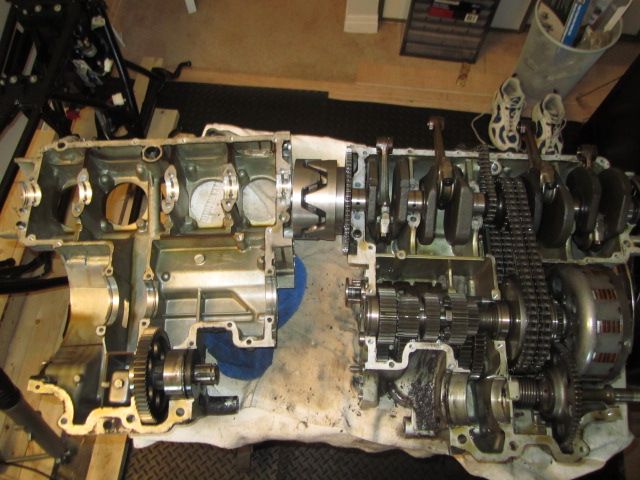

After some whacking with mallets and wood blocks etc ... they separate!

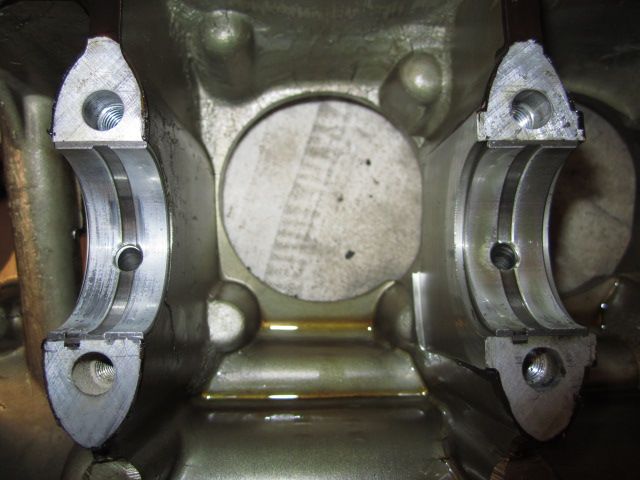

Top half looks pretty clean. Mains look nice.

Interesting ... now what...

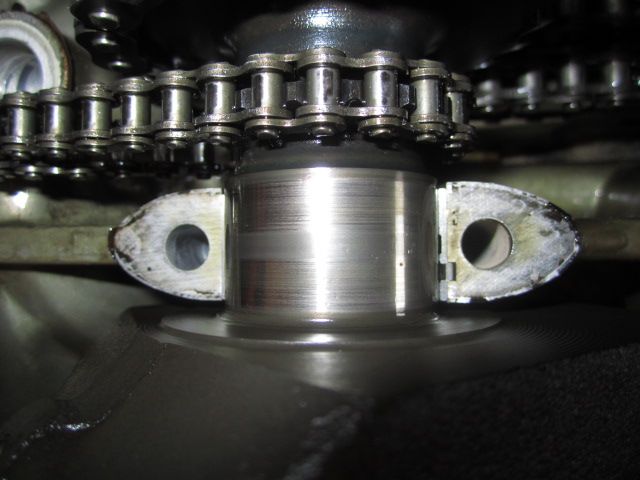

Center crank journal. The flash makes the lines look like grooves but you can't even feel them.

Mains look nice in the top half.

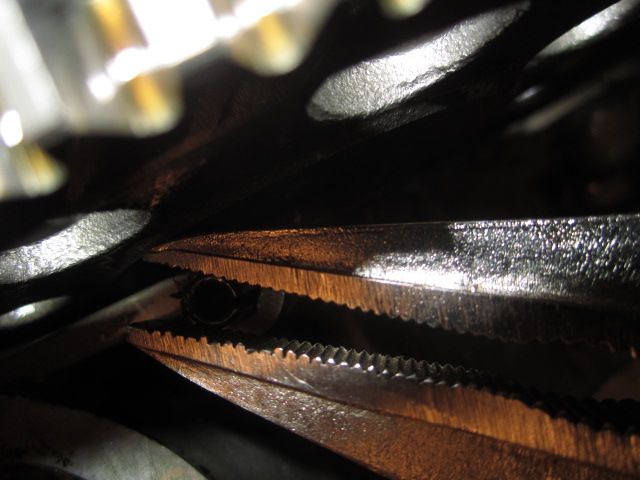

Shift forks out.

All the wear pads look pretty nice. No gouges or scratches.

Shift drum and shift fork.

Roll pin that holds the kickstart gear in place was a bit of a bear. I used vice grips to "close" the roll pin as much as possible.

And ever so slowly rocked it back and forth until...

It finally popped out!

Oil catch tray that sends oil to the auto lube for the drive sprocket. I think I'll leave this out since I run an o-ring chain.

Fruits of my labor. I haven't torn it completely down yet but everything looks pretty good thus far.

A neat shot I thought.

A peak of the mains from the top half.

Closeup.

Anyone know where this is from?!?!?!

Looks like a dowel pin but not the same size.

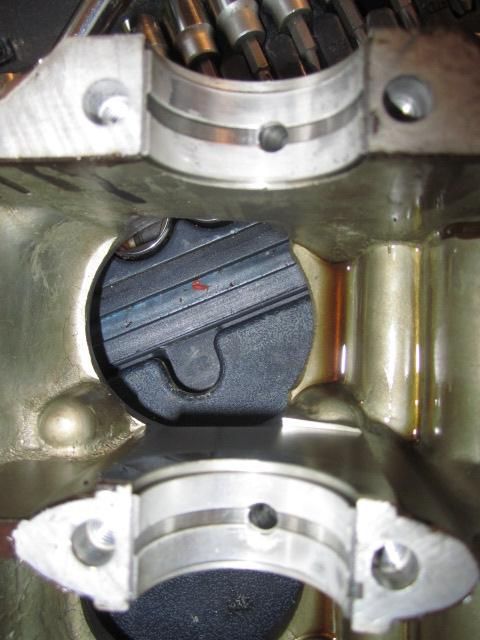

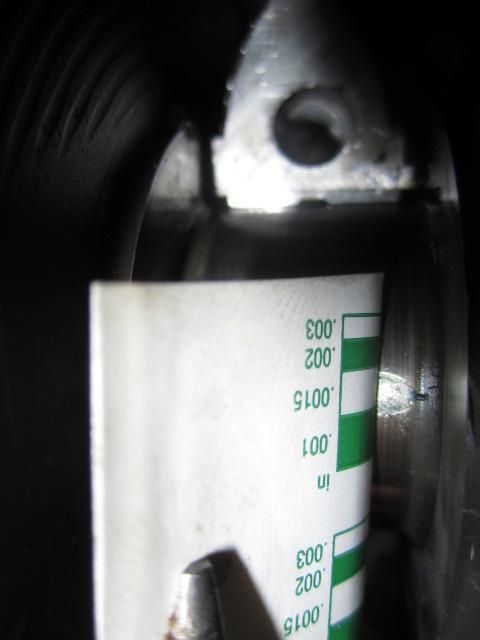

Break out the plastigage.

I actually ended up checking the mains twice because the crank slipped and spun around the first time ... the second time I offset the plastigage to avoid the oil hole.

Reassemble and torque to 17lb*ft.

This was main closest to the points and had the widest tolerance.

Working across the tolerances got a bit tighter.

As tight as .001 on the alternator side.

#4 rod bearing opened up.

#4 - .0015"

#3 down to .001"

#2 rod - .0015"

#1 rod - .001"

DISASTER!

Overall I was pretty pleased on saturday. Most of tolerances are within factory new spec and all well within serviceable limit. The bottom end shall remain untouched other than a crank balance.

I'll post up my Sunday's work in a moment.

IW