Well I had glorious plans of getting sooooo much done today because I had the day off. Well after sleeping in a bit, going to the machine shop to pick up my engine case (finally), getting raped by said machine shop (more on that later), dropping the parts off at the glass bead shop, tooling around in the man room aimlessly cause I was too angered over the raping, and then having to go and pick up the gf from class. I finally got to business and got a bit done but of course not as much as I had planned.

I decided to start off with something easy: inspection.

I figured I better give all my internal parts a good once over while my stuff is at CycleX. That way I can order anything I need and have them ship it to me.

I inspected all the mating gear teeth and dogs. Checked that all the bearings rolled smoothly with no play or noise.

All looks good in here.

Female dog. (teehee) Very minimal wear. Slight rounded corner but nothing I'm worried about.

Secondary shaft. Right?

Dogs have minimal wear.

Slight amount of wear around the edges. Nothing serious. I'm not concerned.

Still not concerned.

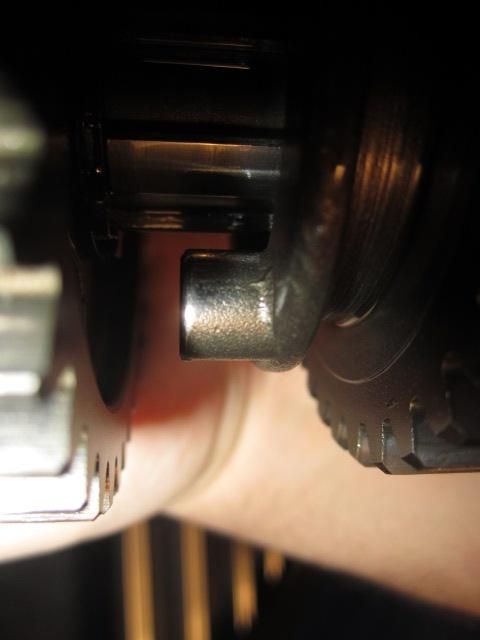

There is a screen or something in the final drive. Does that come out?

Gave it a wipe down. Checked the bearing. Seems to be in great shape.

Shift forks a worn but very evenly. Looks good.

Grooves on the shift drum all look good but I wouldn't expect this would be a high wear item anyway.

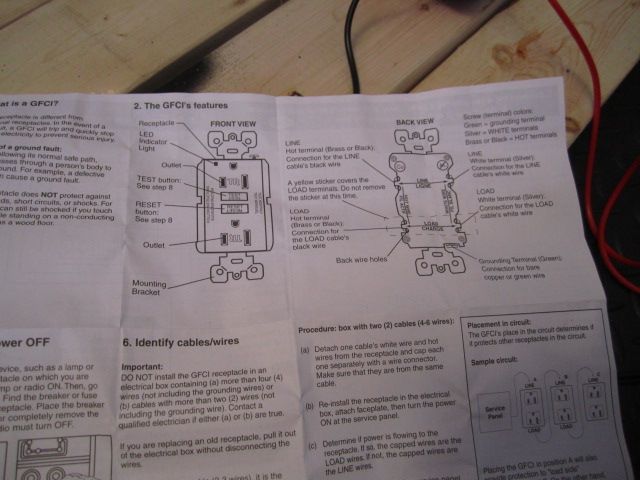

Finally got to something I should have done long ago: installed my GFCI outlet.

Find the breaker and make sure you've turned off the right plug.

Make sure you're measuring A/C voltage. I've using the 200v scale because that is the closest to the expected 120v without being under rated.

Once you're sure the power is off to the outlet remove the old style outlet. Separate all the wires and make sure that none of them are touching.

You can see in the back of the outlet that the white and blacks come in pairs. Find out which white goes with which black. If there only is one set of wires then you've answered your question. You have the "line" wires. If there is another set of wires that means that there is one set of wires coming in to feed the outlet and one going out to go on and feed more outlets. The ones bringing power in are the "line" wires and the ones feeding the next circuits are the "load" wires. You can figure out which is which by turning the power back on (wires must not be touching!) and using your voltmeter to find the pair that is hot.

Consult your instructions of course to figure out where the LINE wires go and where the LOAD wires go.

Hooked up as per the instructions.

All back together. Now turn the power back on and hit test to make sure it trips out. Mine has a little LED to show that it's working. Hit reset to resume power. All your outlets "downstream" or ones that are connected to the LOAD side of the GFCI plug will now be GFCI protected. I was hoping it would protect the other outlets in my shop but it didn't work out that. Oh well. This is the one that I use for zinc plating and that is definitely the highest risk of shock.

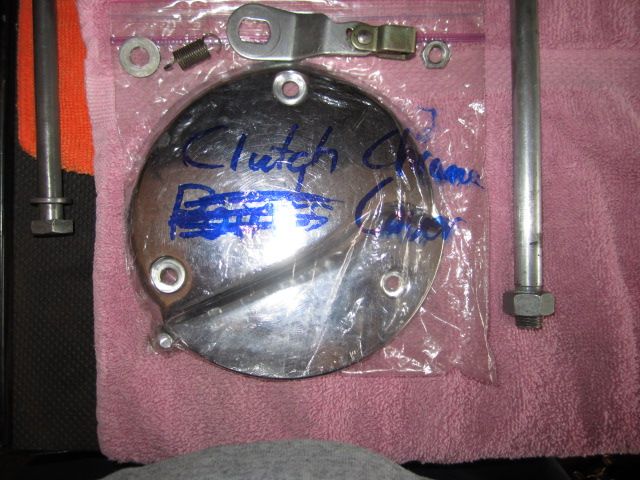

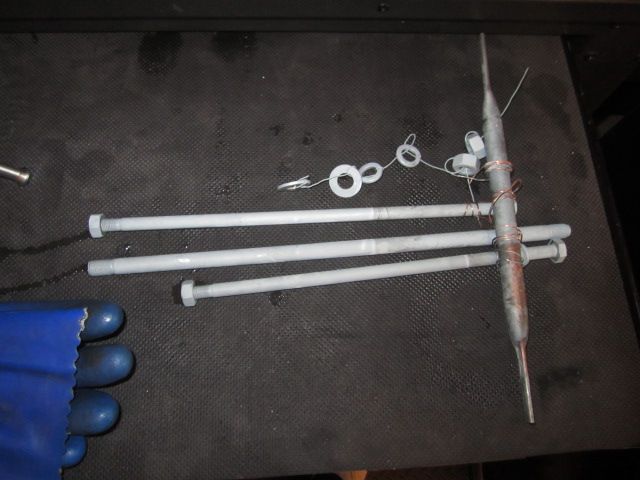

I figured I'd do some more zinc plating since I have a bunch left that needs done before much else can go back together.

Engine mount bolts.

To help me remember what goes where.

This goes in this baggie.

That goes in that baggie...

etc

etc

etc

This clutch lifter/adjuster comes apart and there is an o-ring in there!

Wire wheeled the engine mount bolts. Looks better already.

Degreasing.

Rear engine case bolts before wire wheel.

After wire wheel.

Degrease the other end.

These are cam chain tensioner bolts... Anyone know if these are chrome??!? They look pretty shiny for zinc.

Decided I'd delve deep and even take the advancer apart. It's not too hard. Just have to pop those tiny e-clips off with a pocket screwdriver.

Wire wheeled.

The end of the axle shaft looks chrome but the rest of the shaft looks zinc... is this correct?

Everything prepped and ready for zinc.

First batch out.

Cleaned up.

Protected from the elements for another long time I hope.

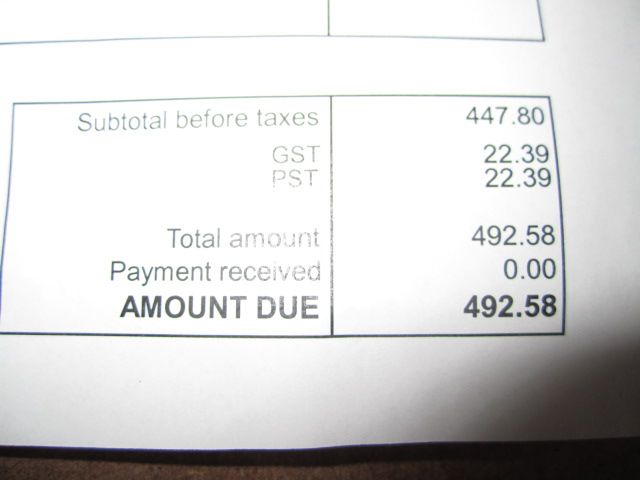

Oh and the Piece De Resistance ... that really made my day. Actually made me speechless at the machine shop.

Yep. That's right. $492.58 to remove one stud and fix one thread boss for the points cover. They managed to TIG a nut to the stud and tried to pull it out but it snapped off like 1/2" below the surface so then they had to set it up in the mill. There really isn't a lot of good places to set the engine cases up off of and the cylinder surface is at some weird angle so he would have to rig it up 90 degrees to that somehow.

Anyway, I was expecting $150-$200 and when I saw that I just about #$%* myself. Oh well I guess?

IW