Here's an update from Friday Night/Saturday ... yeah I'm cool and stay in on Friday night to work on my engine. ha The crank seal ended up showing up that I ordered from Cycle X ...UPS Express. Don't ask how much it cost. So thanks to them for shipping it quickly and getting it to me in time for the weekend.

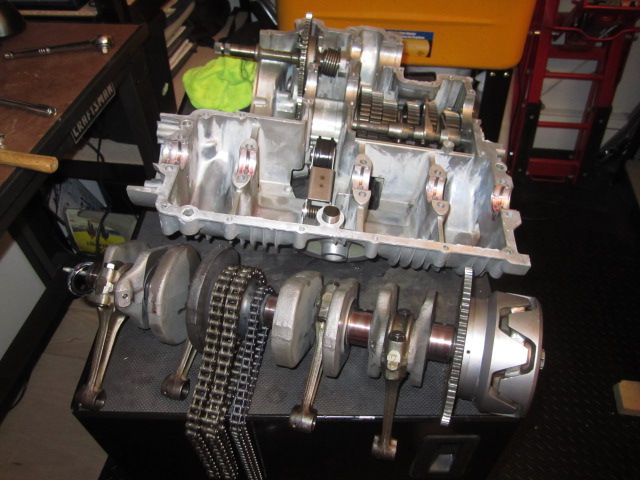

So we meet again split cases...

Not what I wanted to see after having sealed them up once already.

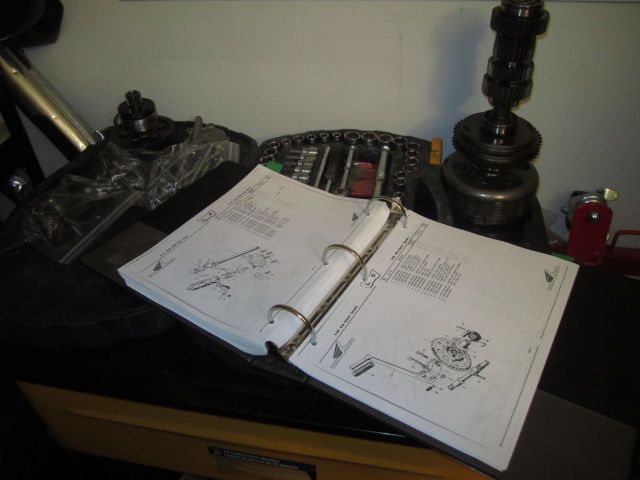

Parts parts parts.

What all the fuss was abuot. You can see the trimmed shoulder of the seal and how I just used some threebond to hold it in. I thought it would be fine ... and maybe it would have been... but it was eating away at my soul! I had to fix it.

So I scraped all the threebond off and started again.

Went much quicker this time despite having only 1 pair of hands.

Last time I used the impact to drive on the alternator ... this time I decided I might as well check that it was torqued properly to 75ft*lb... this is how I locked the crank. Worked well.

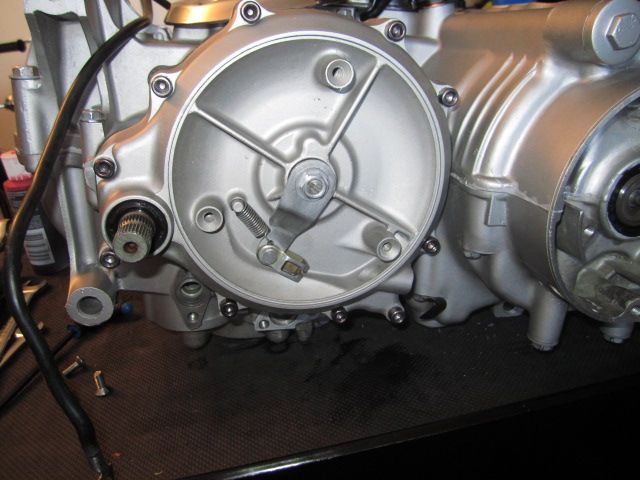

Back to about where I was before. Only a few hours lost overall.

The rig I worked up to test my shifting. Vice grips on the end of the advancer rod to spin the crank... 2x6s with a screw to hold up the chain so it doesn't jam.... hahaha

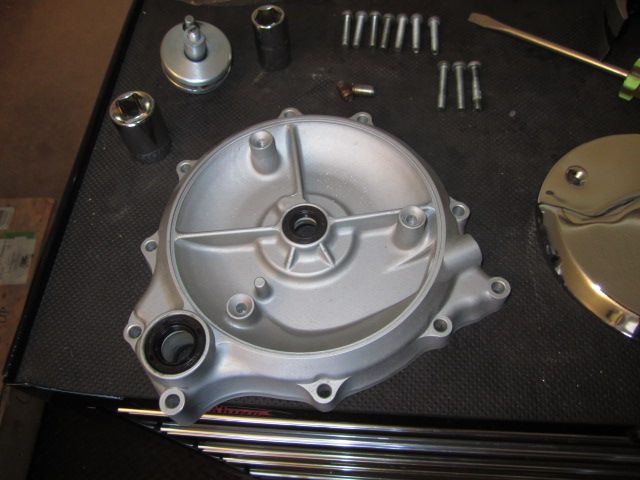

Shined up the right side covers a bit.

Popped in some new seals.

All together with the clutch mechanism in place... I'm undecided if I should replace the o-ring on the advancer rod thingy and the clutch adjuster. I'll have to open that side up again if I do I guess.

Oooo shiny!

Thanks to whoever pointed out that this gasket was for the pump. Decided to replace it now.

The old gasket was paper thin!

Locktite on the philips head screws since they are tough to get real tight. This is about as far I as I can go down here since DSS didn't send my oil pickup screen. ARG!

I threw a set of rings in the bore and checked the gap. Top gap was right at .009" and second ring gap was .012"... seems a bit tight to me. Anyway?

I also threw a piston with rings in the bore and it seemed reaaaal tight. Hopefully that's normal. I didn't have much oil or lube on it so that's probably why I guess.

And #$%* was getting a bit out of hand in the shop so I stopped to do a major re-organization.

So that's about as far as I can go with the motor until I get an oil pickup screen from DSS (if they believe me that it was missed by them... I'm not that happy with their service overall) and get my head studs from Dynoman.

I also stripped out the remainder of my liner in my tank using paint stripper. It worked pretty well but still left some in the corners. That stuff is tough as nails!!! I think I'm done with trying to remove the rest. The stripper was really nasty stuff to work with and I don't think whats left is going anywhere. It's survived 15 years of fuel, tumbling abrasion in the dryer with screws, and now paint stripper too. The chunks I pulled up from the bottom were like hardened tar or rubber. Super tough stuff. Would have been a good lining job if it was applied properly.

Major things left to do:

-Finishing treating the inside of my tank

-Lace up the rims to hubs

-True the completed wheels

-Finish wiring

-Find a shop to do my paint (decals and emblems on the way)

-Order new seat and other small bits like harness ties, etc

-Finish top end build once head studs arrive

-Get engine back in bike

-Tear down carbs and clean them up for blasting ...maybe

-Disassembly to go back down stairs... lol

IW