Okay, here goes:

From your description you are looking at something like this:

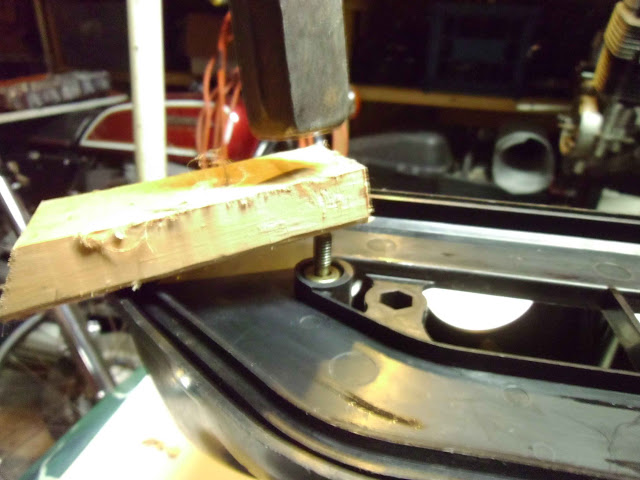

And these are the tripping point. Notice the untreaded portion of the bolt:

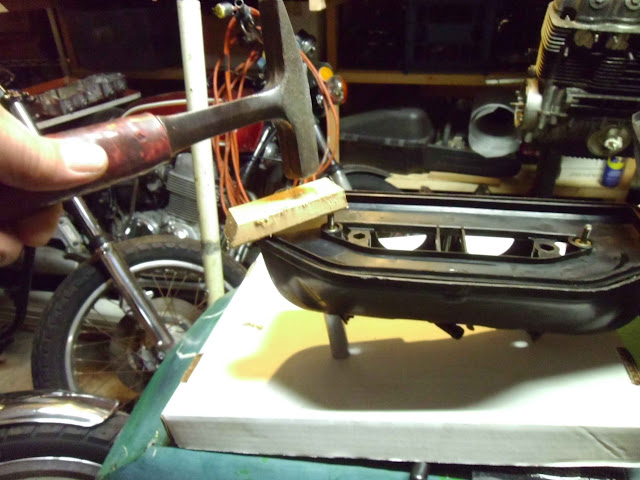

You are going to want to support the bracket, the bolt must be able to move freely. I used an oversize socket (12mm or 14mm deepwell):

Use a block of wood on the end of the bolt to protect the threads. Strike sharply, BUT NOT TOO HARD! The airbox is plastic, start easy and strike a little harder until the retainer moves. Did I mention DON'T OVERDO IT:

You are trying to get the retaining nut(?) to move up the unthreaded portion of the bolt. This retainer is threaded, but over time it gets jammed on the shoulder of the bolt (as we will see in a following picture). My guess is that ham-fisted tightening of these bolts jams this retainer onto the shoulder of the bolt:

Once the retainer moves, then you can unscrew the retainer from the bolt. The retainer nut(?) is threaded, and you will likely need to grasp it with vise grips. ONLY TIGHT ENOUGH TO HOLD IT! Too tight and you might crush/distort the retainer nut(?) making it even more difficult to remove:

Here's a close up of the freed retainer nut(?). Notice the little wrap of loose thread that was a result of the retainer being jammed against the shoulder of the bolt. You can see the shoulder on the bolt in this picture:

Assembly is similar to the reverse of disassembly (except for the hammering part!).

Easy-peasy