The Cases are joined! And my cylinder is out for honing, should be ready later on today.

Funny story... and an example of why you need to completely document your teardown.

So, I was ready to join the cases, had my Yamabond (I know, I am a traitor,,,) applied to the upper case. I made sure that the gears were in neutral and lined up the shift forks on the top case.

I could not get the cases to line up, no matter how I wiggled and finessed. I was close to tearing my hair out.

I pulled the upper case back off to try again. As I was looking at my shift forks I realized I was missing the Transmission Locating pins (#16 in the diagram)

I started tearing through my bagged parts, including the empty glad bags where I had stored the Transmission assemblies. No joy. Now I was really pulling my hair out. How could I lose these? I was so careful about not letting anything get lost.

I went to my computer thinking that I would have to order them, which meant cleaning the upper case of the rapidly drying Yamabond and waiting another week for delivery - assuming these little guys are even available. Man, I was steamed!

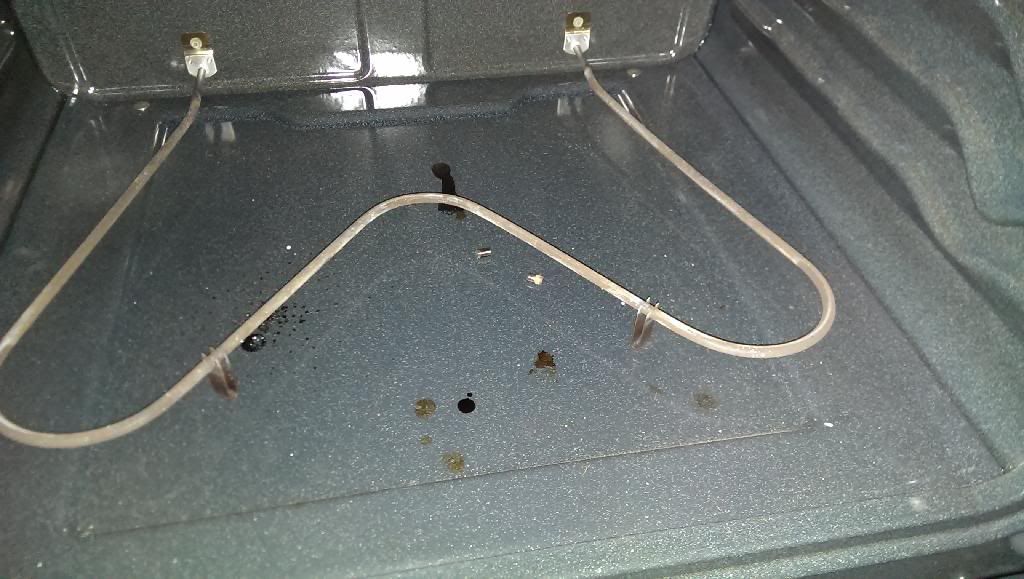

Then I realized,wait a minute.... when I was powder coating the cases, I had noticed some metal cylindrical pieces at the bottom of the oven.... I thought they were some seird part of the oven, like temp sensors or something, could it be possible?

YES!!!!!!!!!!!!!

Ahhh - crisis averted!

I insterted them in the right place, refreshed the Yamabond and weirdly, everything literally dropped into place with no effort. Weird, but welcome.

I inserted and tightened up the 6 uppercase bolts and then flipped the engine over to torque the 10 8mm bolts that hold the crank into the case, following the proper sequence.

I torqued them to 17.5 FTLB as the manual gave me range.

I then inserted and tightened the remaining 6mm bolts around the outside of the case.

All said and done, there is a nice, thin and even bead of Yamabond around the case. I think she's ready to hold oil.

Ready for the top end!

Gratuitous pics:

Gersh