There is a bit more progress on the bike finally! I haven't been able to work on it for the last few weeks, as work was super hectic!!

I made a quick mock up for the seat I want to make. Before I could finalise this, I needed the dimension for the rake and trail.

There was the possibility I might had to get the swing arm shortened, but after a ton of math by the CNC and race bike building expert, he told me it is fine like this. Taking into account the wheel size (both 17"), the shorter shocks and the longer swing arm this apparently is all good.

I want to have the rear hoop end right over the rear axle and the angle the same as the left upright for the triangle the side covers sit in.

Since this will be a daily driver, I want an electric starter and all electrics working (including indicators), so I'm making an electrical box under the seat. It wil also have space to carry a big chain lock, as I want it locked to something overnight and carrying in my backpack is a pain in the ass.

I wanted a maintenance free battery to avoid troubles, so I got a Ballistic battery. Heaps expensive, but super light and mountable in every position you'd like.

The steering would make a loud CLUNK if I rode of a curb at low speed, like it fell down into the races. Now that it was all out and I could really get a look at the thing, I found out the races weren't hardened steel and too small. Getting them out was a pain. The bottom was fine, the top was sitting over the little edge that inside the head. Ended up welding a big washer to it and hammered it out. New bearings are already in!

On of my biggest worries was the rear swing arm. Once I found out the wheel didn't fit the original, I had to go out and find a replacement. The '04 ZX6R swing arm is the most basic but I couldn't find any dimensions on it. I found one at the dealer with the right swing arm and did a 'measurement' on it, to see if it would fit the frame at all. I looked like it would, so I ordered it. It was only €40,-! (about $50,-), so worth the risk.

Once I got it in, I realised the rear axle of the '04 is longer and I already had an '05 axle...so an '04 axle is on it's way.

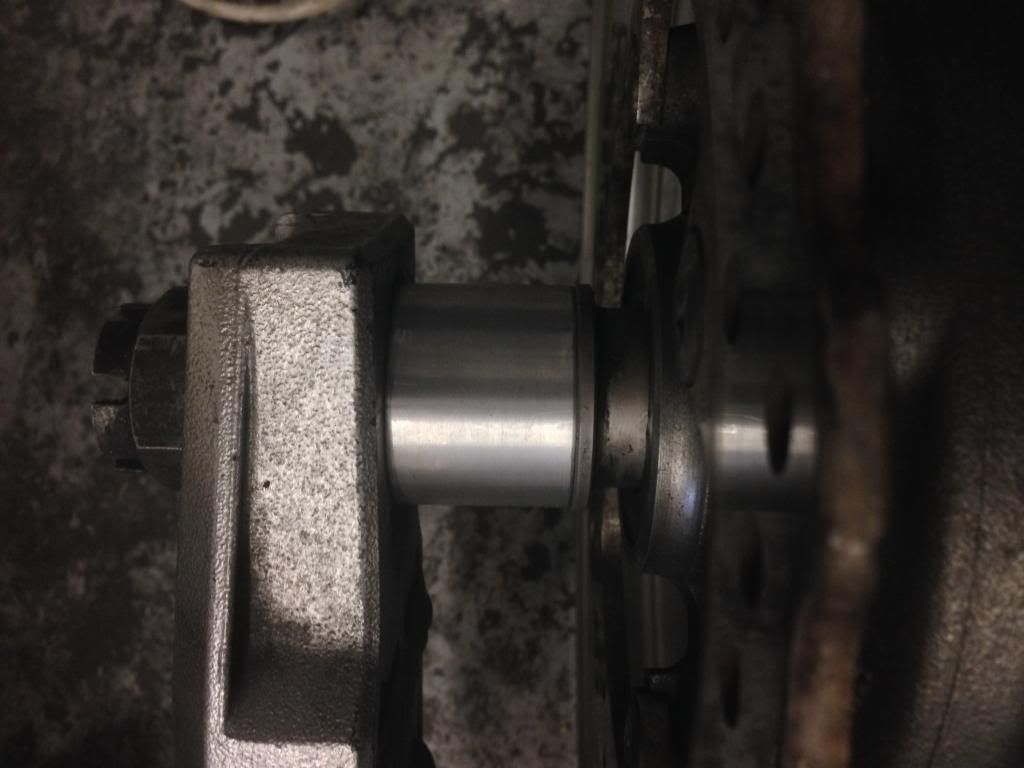

The pivot side fits like a glove fortunately! The problem was the swing arm axle, which was twice the thickness of the original. Opening up the frame would be a massive pain, closing up the swing arm was a better option. The CNC guy I work with came up with the best solution as one side is a needle bearing, the other a regular ball bearing: he openend up the new axle (which was hollow) and fitted the original in there. He used the excess axle as a spacer and dust cap. Brilliant! He also made me a set of new spacers, one need to be taken down to accommodate the rear break mount.

Both axles:

Old in new:

Regular bearing:

Needle bearing:

Spacer 1:

Spacer 2 (note the brand new sprocket I got with the wheel for free, free is fantastic!)

I finally got the putting the engine on a mount to start work on it. I opened up the head before and noticed a lot of adjustments that were out, which would cause the problems I've been having. So I hope a tune up will fix most of it. I will replace the cam chain, as it was hitting the block.

I don't have the time to split the block all the way and have a look at the gearbox, because third gear slips out when I pull away with high rev's. My clutch plates are done for, so that might be part of the problem. It only happens at high rev's and relatively low speeds. I know this is a "common" problem with the CB750, but it will need fixing when I got to 836/900 cc's.

I took a full day to completely clean out my carbs. They were in really good condition inside still, so it was mainly dirt and grime that was caked on the outsides.

Clean as a whistle:

I went to work on my exhaust and tank, to prep them for paint. The bottom of the tank was really filthy and had some rust. Because of the shape of the tunnel there was no way I could get to it all without sandblasting it. My exhaust was pretty rusted and really pitted, so de-rusting it by hand would've taken me days. So I went to the blasters and had them both cleaned.

The exhaust still has some rust colour on it, it was in my car for 3 days as I didn't get a chance to paint it yet. The tank was perfect fortunately! No big dents or things like that, I did find a small one today after paint, but it's very minor.

The original plan for a paint job has been put on hold for now. The original plan was a matte dark grey base with a high gloss paint job, but the combo of matte and gloss 2k paint is a pain, possible but a pain. So for now, just a matte dark grey tank, side covers and fenders.

The exhaust matches the wheels, which is a silver grey finish. When it gets it's full paint job the wheels and exhaust will get matching colours to the rest of the tins.

First layer of primer:

Since it was the first layer and I couldn't be bothered cleaning out the barn to make room for an improvised spray booth, I hung it all in a tree and got to work. There was no wind today, otherwise I wouldn't have been able to get this done.

This is the first layer of paint. I used a roller, I know I know!, as this will be temporary and I didn't want to mix paint 4 or 5 times for a gun (I don't have my fenders and side covers yet). This layer will be wet sanded, another layer, more wet sand and a matte 2k finish.

Next week I will start on the block and hopefully finish it. The triples are being made, the hoop will be welded on and the electrics need to be sorted. I'm getting there finally!

There is a bit of a rush now. In my spare time I'm a surf instructor and I work at a camp in Spain as well. I will leave the 28th of June till mid/end september, so I want this finished before I leave and bring it with me. Just need to figure out how to shoehorn this into a Volkswagen T3 camper (with full interior), with about 6 surfboards and space to sleep. I might bring a trailer, but it's such a pain always!

Anyone has any tips on any of this, I'm always open to suggestions and tips!