Made a bit of progress tonight. It wasn't without a couple stupid NOOB mistakes... but I guess that's to be expected.

Lapped the valves. I couldn't find any of the engineer's blue. Tried to use a sharpie, but it didn't work too well. So I just lapped as little as needed to make the surfaces smooth and spot free. Made the mistake of starting to lap the intake from cylinder 1 into cylinder 4

Somehow since the head was upside down, so was my logic.... Caught it, luckily...

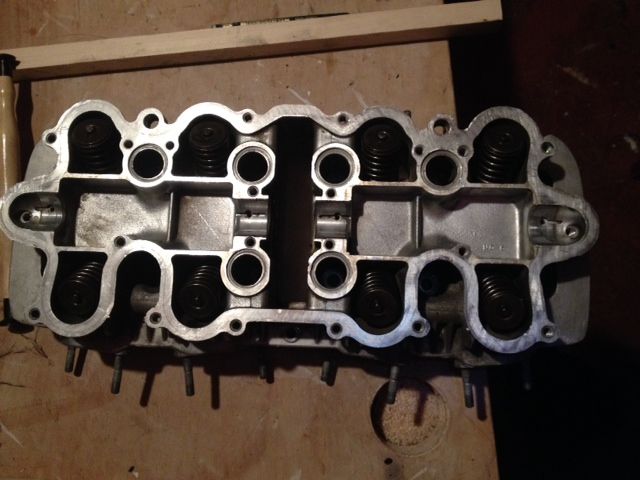

Then decided to go for it and just put the head back together. Clamped it down so it didn't bite the concrete floor

Actually went together much easier than expected. The valve keepers are so tiny, that they were tricky at first, but after the first one, I got the hang of it pretty quickly.

It's late here for a weeknight, so I'm calling it. Gonna get some gas and do a leak down test tomorrow. Fingers crossed as I'm really just learning. I've realized through this process how much of a craft this actually is. I mean, you can watch a youtube video and read manuals on how to tile your floor, but its not gonna look as good as a professional's work. Hopefully this leak down test passes and I can start putting this back together. Longest I've gone without riding in a few years.