Spent all day cleaning the engine parts to get rid of any left over glass bead media. I ran a tap through all of the threaded holes in the case to clean them out thoroughly. I also drilled out the rivets that hold in the windage tray so I could thoroughly clean under it.

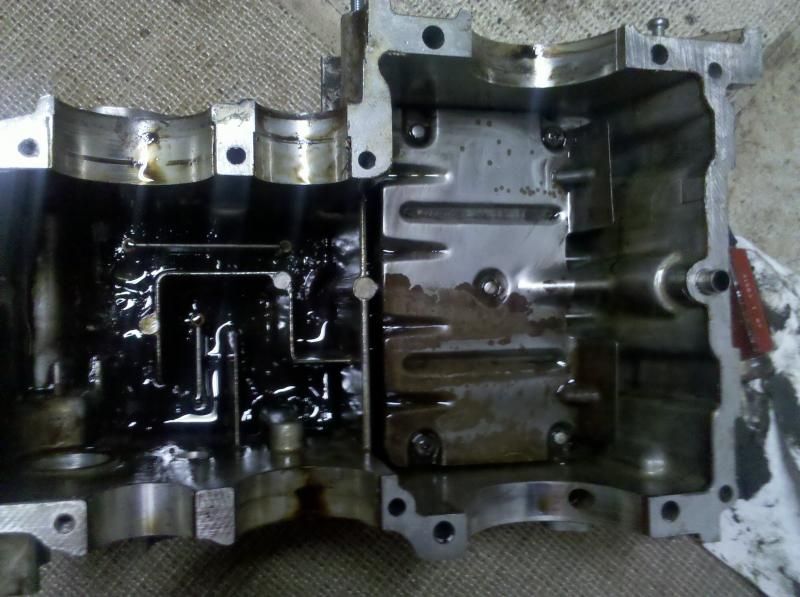

Originally (not my case since I forgot to take a pic of it before I removed the tray)

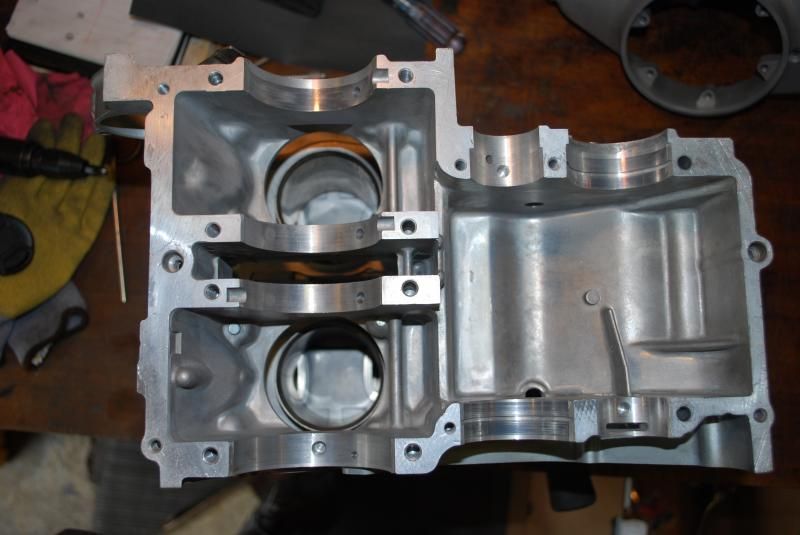

As it is now.

All clean underneath

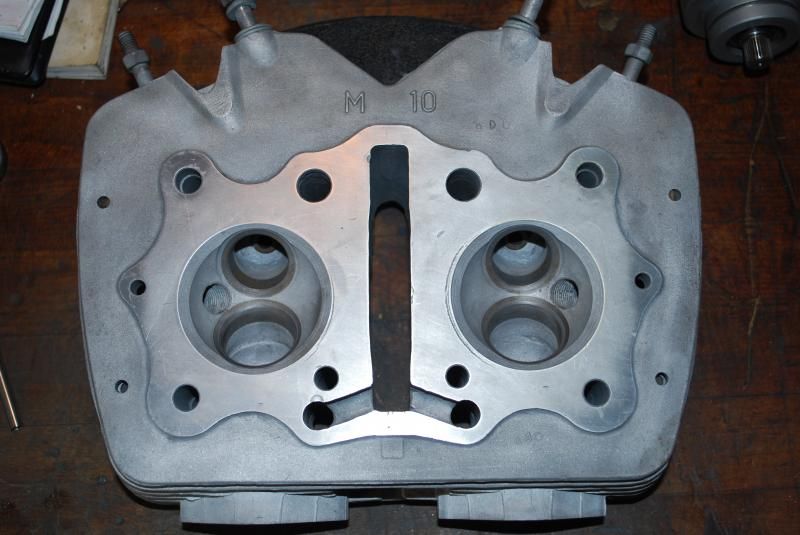

I spent some time lapping the valves. The seat on the valves looks good, but not the ones on the head. I will do a leak check after I get the head milled to accept the new cam chain slipper. I stopped by a machine shop this morning that is just down the road from me to see if they would do it and how much. The guy was supposed to call me back, but as of right now I have not received a call.

I took apart the starter to clean it out and check the brushes and what not. There was A LOT of dust inside, but everything looks to be in good working order.

I also spent some time working on the mating surfaces. It is amazing what is brought to life when you remove a little bit of material. There are all kinds of little casting flaws. I guess I have some more work ahead of me to try and get a few of the scratches out.

And a pic of the inside of the upper case half.