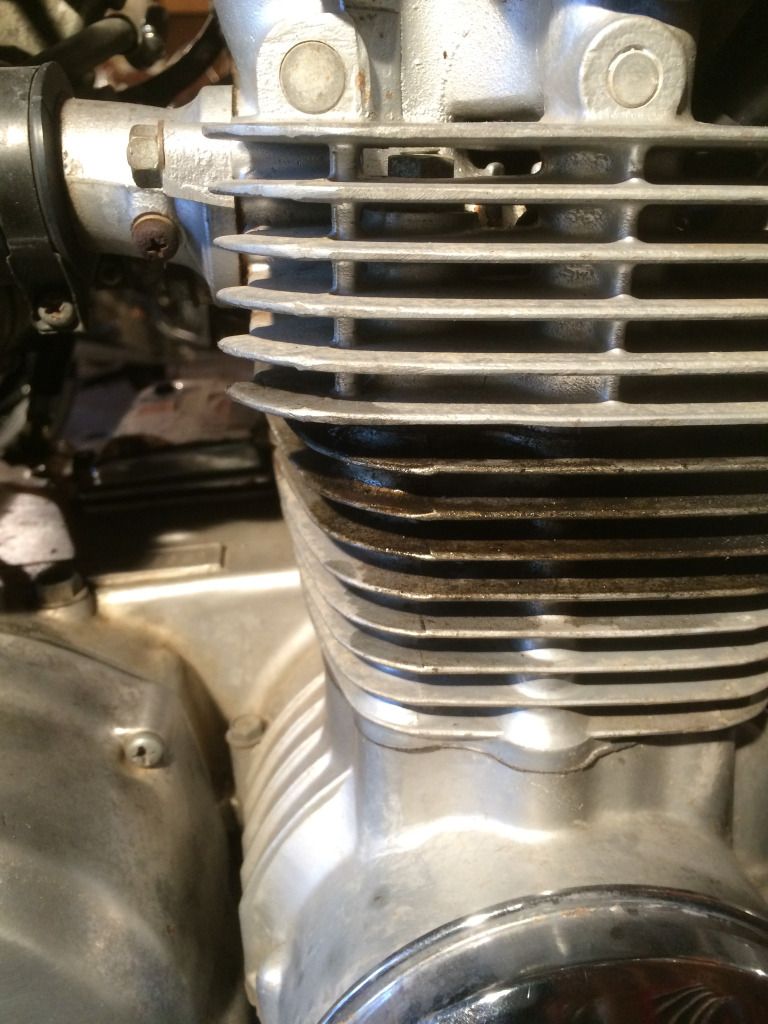

Since I picked up my '72 CB500 a couple of years ago, there's been a bit of a leak on the #1 cylinder. Towards the end of the summer riding season, if I let it sit for too long between riding, the spark would foul-up. I'm new, but I figured they were connected. My winter to-do list has been to get it fixed. I bought the Versah-155 gasket kit and a new (old) Craftsman V-Series ratchet, and got cracking.

I know that you can do the head on the frame, but I pulled the motor anyhow, just to see if I could. Wasn't a problem, solo. Thanks so much for the advice here! Someone described putting a 2x12 under the motor (after removing the oil pan) and jacking it up and out with a bottle jack. Thanks for the tip! Worked great!

Got it off and settled — had a real tough time with some of the valve cover screws. Some of them seemed almost bonded on—got to use my new dremel cutting slots, so that's a plus!

Yeah, part of the fun on this go around has been building out my tool collection. Figured since the bug hasn't gone away yet, it's probably here to stay. Looking at torque wrenches now (anything but HF...).

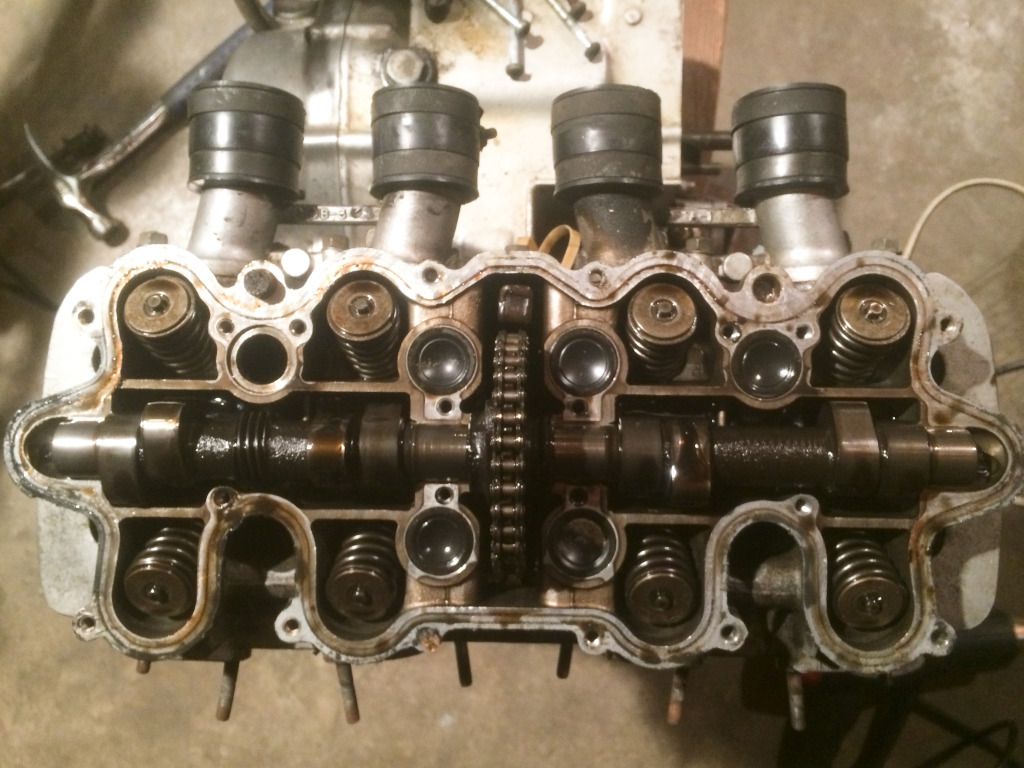

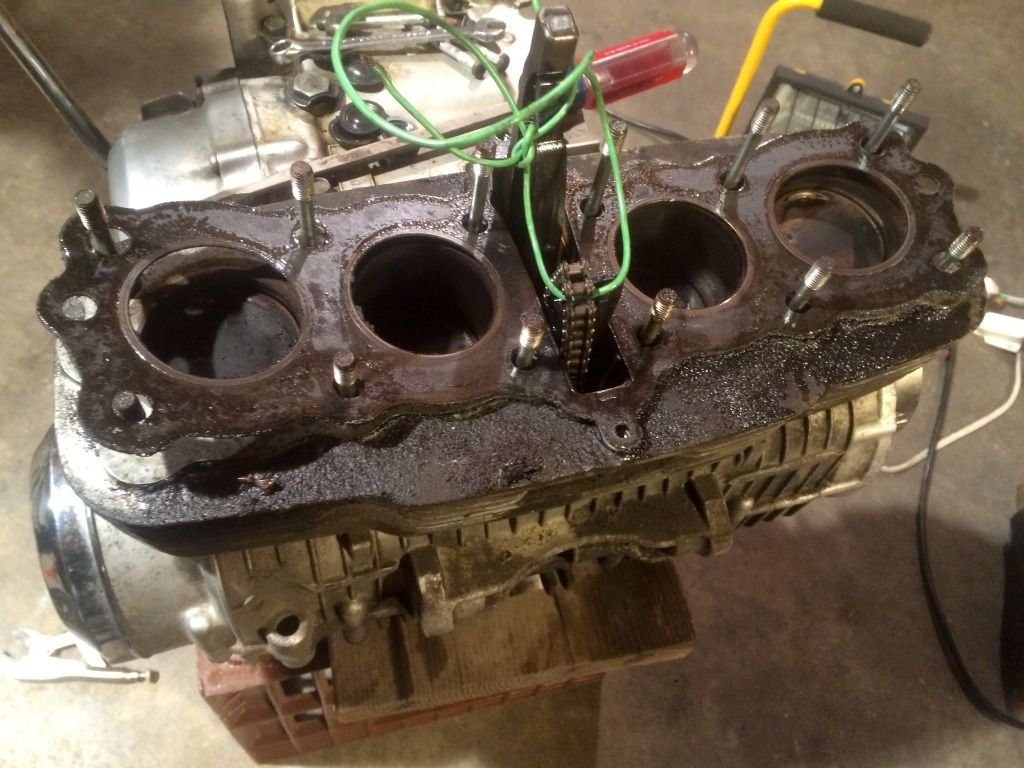

After that, it was all easy! Valve cover came right off — and so did the head. Honestly, I've been embarrassed how long it's taken me to even get the parts straight. You've got the breather cover on the very top, than the head, than the cylinders. To anyone reading this—the jugs are the cylinders, so when folks are talking about jugs, that's what they mean. Haha. All of the advice is so good, here, but sometimes I don't even know the terms. Learning quick though

.

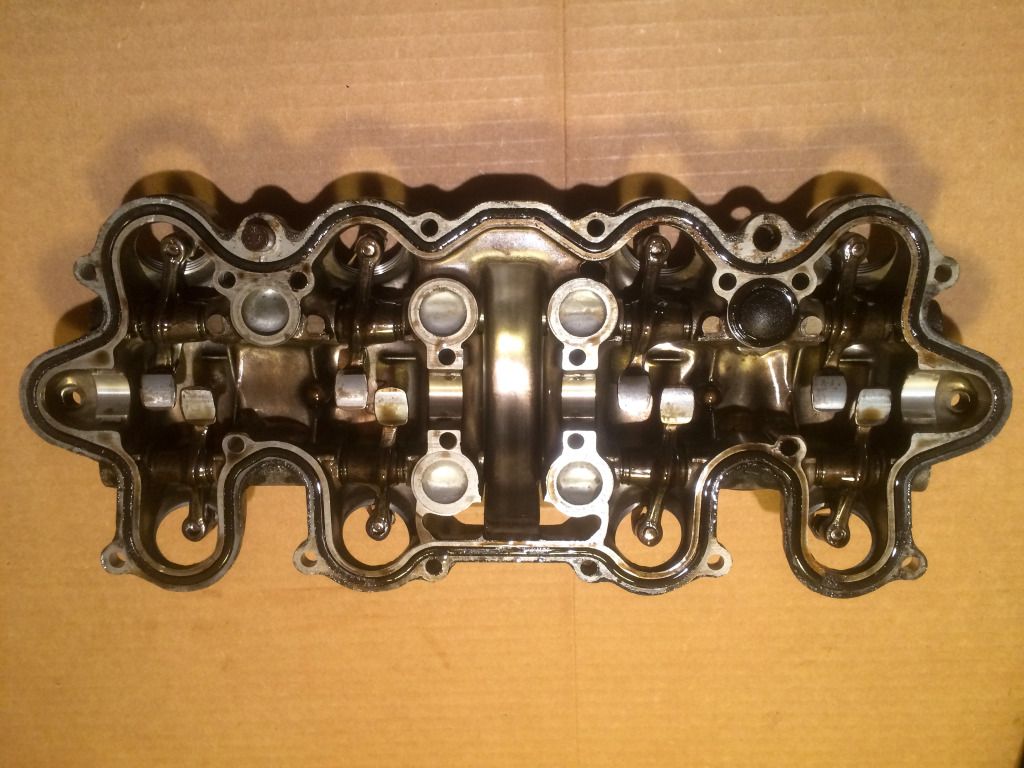

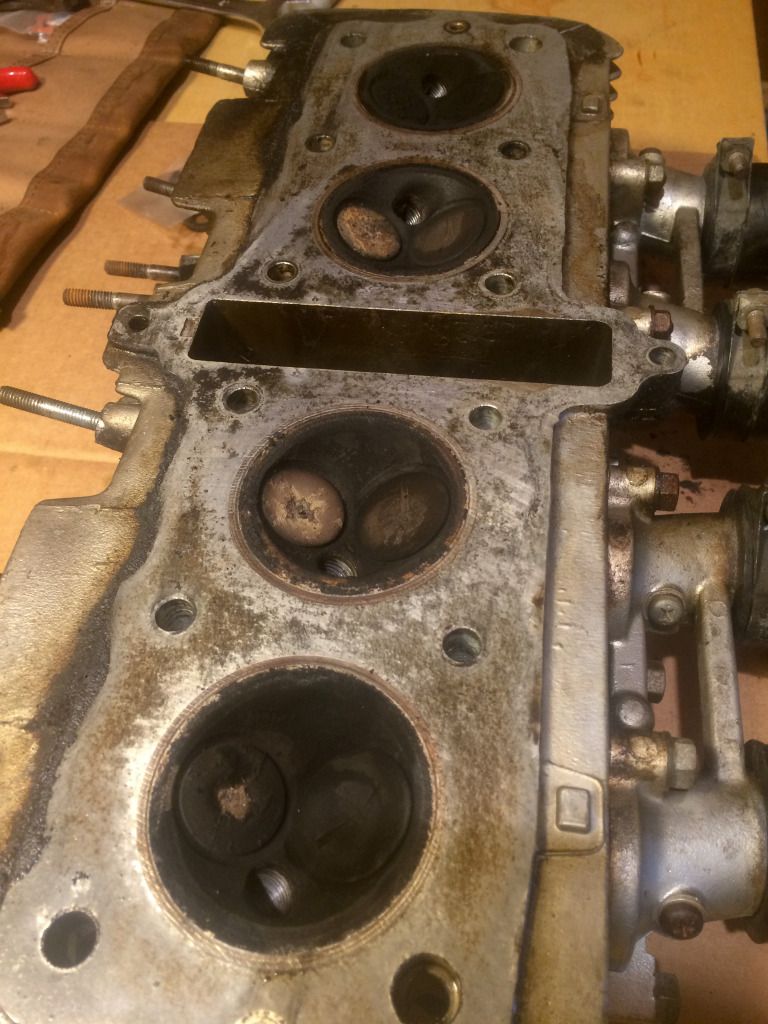

Here's the underside of the valves. They definitely need a good cleaning and all that. I guess I'll need to figure out how to pull em' and lap em'.

The cam looked pretty good, as did the sprocket and cam chain (I think).

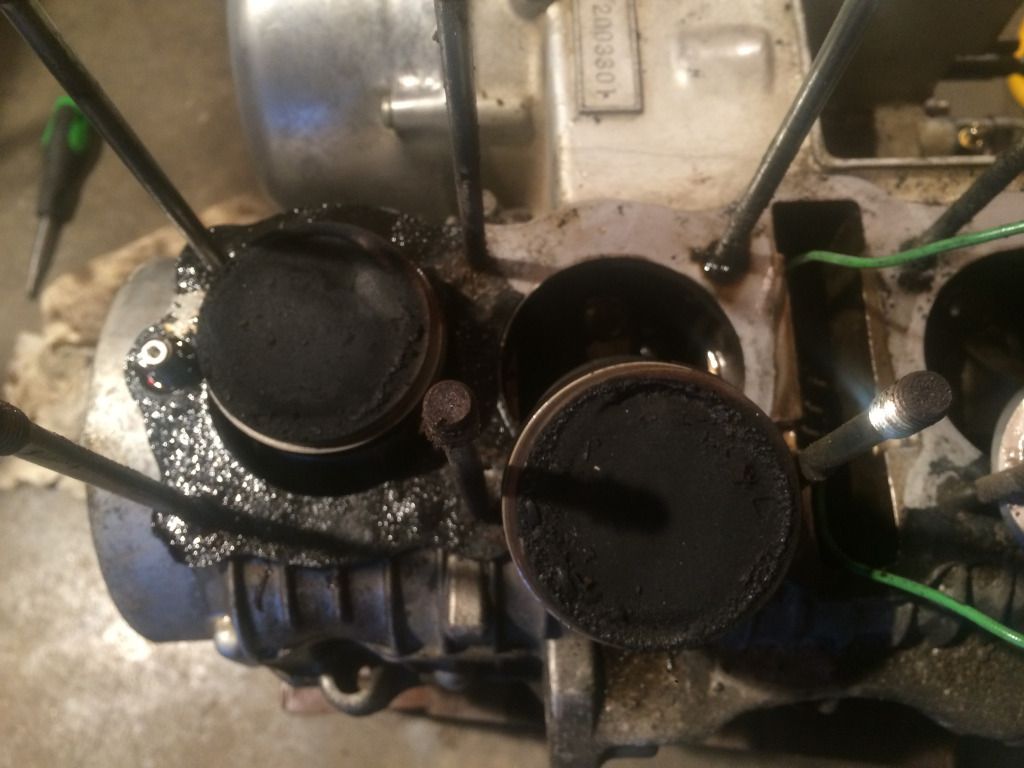

I'd heard that the head could get stuck on there. Not mine. Full of oil & gunk.

The head popped right off with a bit of force under the cc mark — not bad. I think I'll take the cylinders off too and see how that goes.

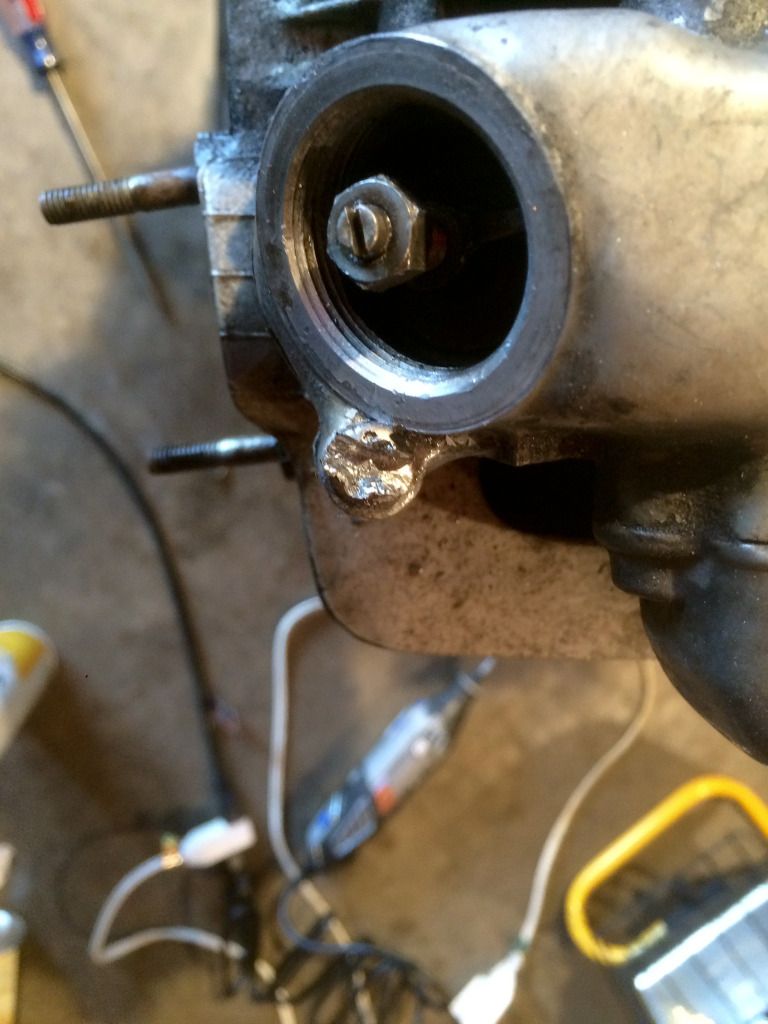

Here's the cam tensioner — seems like it's in good shape. I've read about the tensioner many times, but it's never so clear as when you're holding it right in your hands. Oh, and if anyone is working off of an old Clymer, they tell you to take out the tensioner before removing the head. That's pretty much impossible, I think. Took me a bit to figure that one out.

That about does it! I've been following some really good threads, so I'm looking forward to making this happen! Thanks for all the help and advice out here on the forums. It really makes it all possible!