Ok People have asked and i will provide...

here is a tutorial for drilling and tapping.

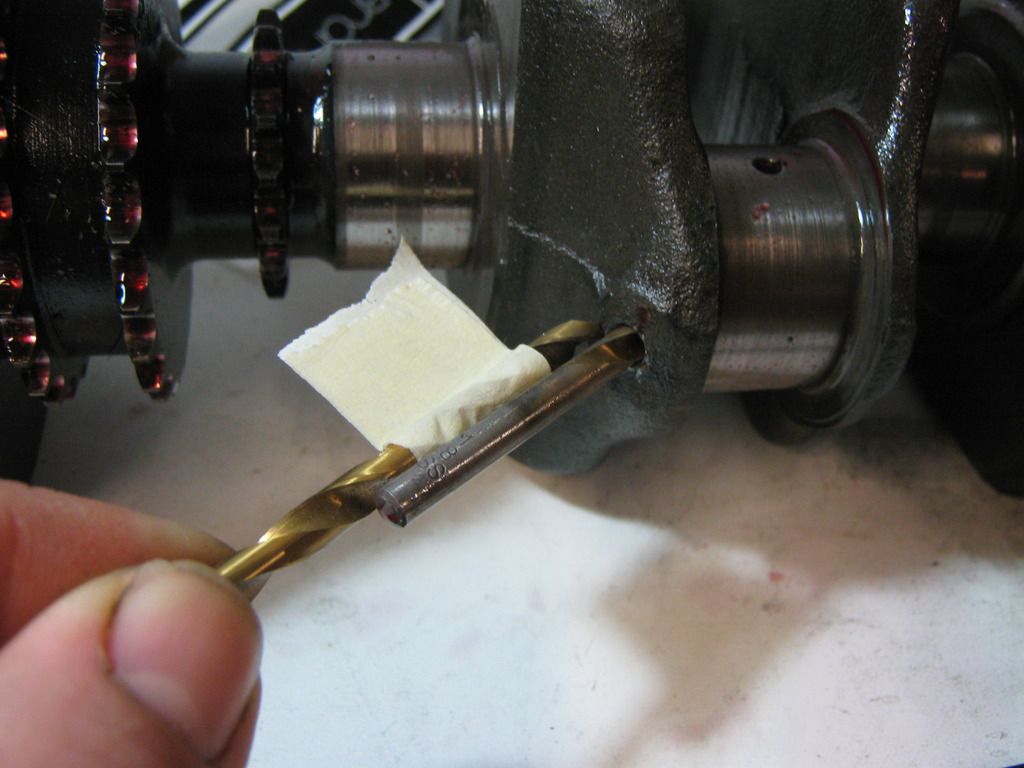

1. Pick your grub/set screws Here I have 1/4"x28x1/4" and 1/4"x28x3/8" these seem to make the most sense 1/2" long seems excessive.

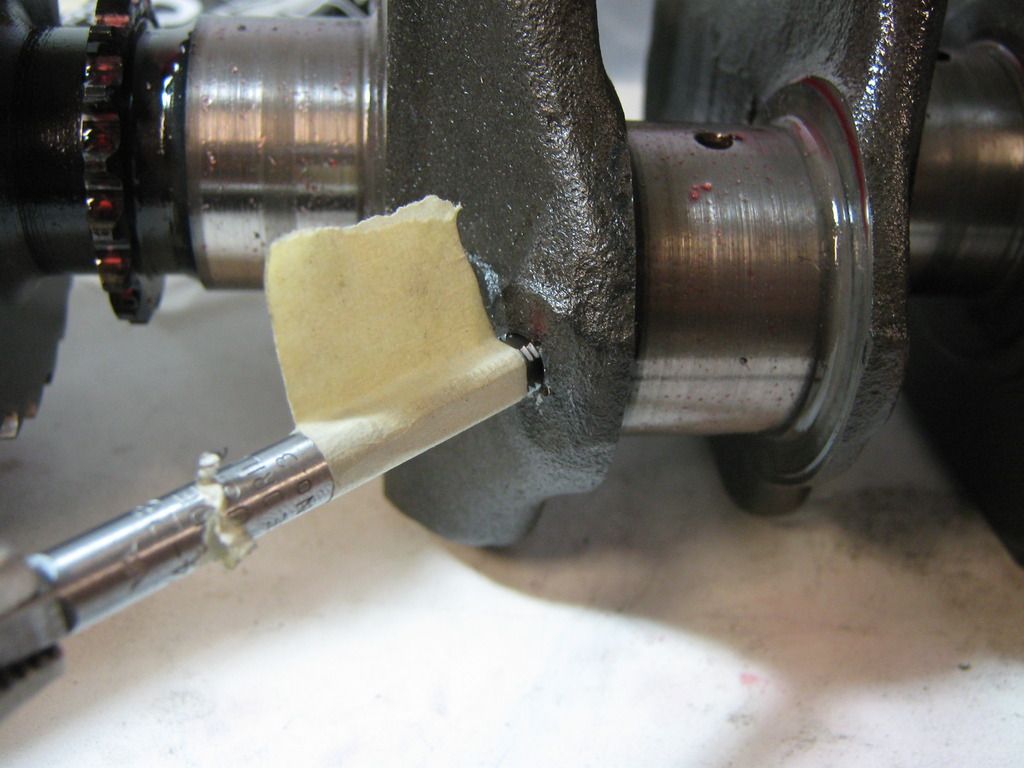

2. Next set up your drill and tap for depth

-the tap depth should be set so the starting of the threads match the bottom of the set screw

-the drill depth should be set so the edge of the flutes are a little deeper than the start of the threads

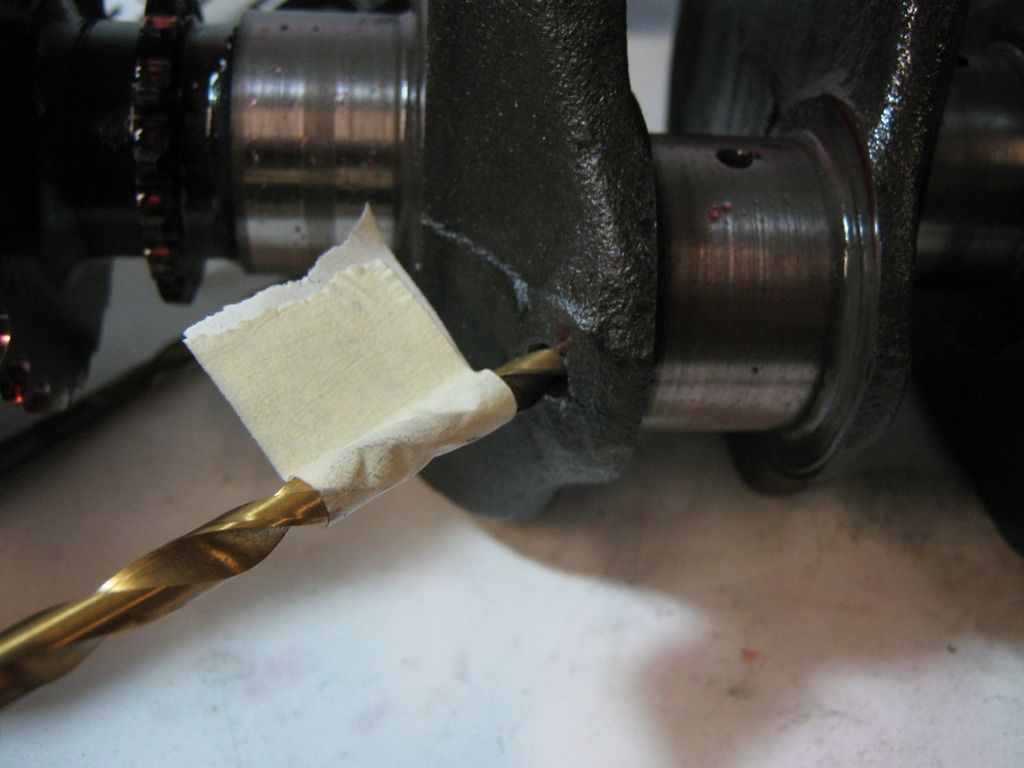

3.Use a smaller drill i think i used a #8 to observe the angle of the hole with the #3 beside

4. Remove the bit from the passage shift the #3 over without changing the angles and drill to depth

** use cutting fluid **

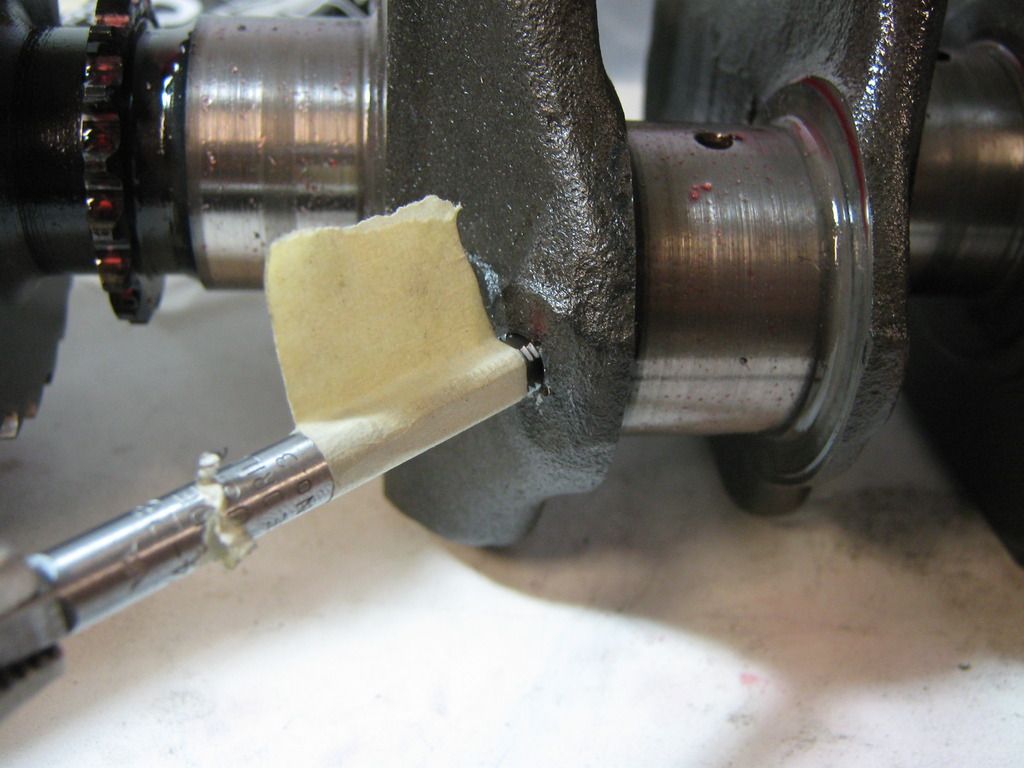

5. Use the same #8 bit in the passage to observe the angle for the tap line everything up

6.Now its time to tap with everything lined up carefully start the tapping. The material is reasonably hard and the tap will need to be reversed frequently to break the chips off.

** use cutting fluid to lubricate tap **A. start the tap get about 1 to 1 1/2 turns on it

B. you will feel it get stiff to turn and bind. STOP and back the tap out about 1/2 a turn to break the chips

C. now turn it back in and cut a little deeper (1/2 to 1 turn)

D. you will feel it get stiff to turn and bind. STOP and back the tap out about 1/2 a turn to break the chips

E. now turn it back in and cut a little deeper (1/2 to 1 turn)

F. you will feel it get stiff to turn and bind. STOP and back the tap completely out and clean the flutes and relubricate the tap also cover 3 of the oil holes and blow out the passage from the 4th (with a rubber tipped air gun, don't scratch the journal)

G. now turn it back in and cut a little deeper (1/2 to 1 turn)

- Now repeat steps B to G until you get close to depth

-If you feel the tap binding at any point, reverse the tap and break the chip, if its still tight remove it and clean both the tap and the hole

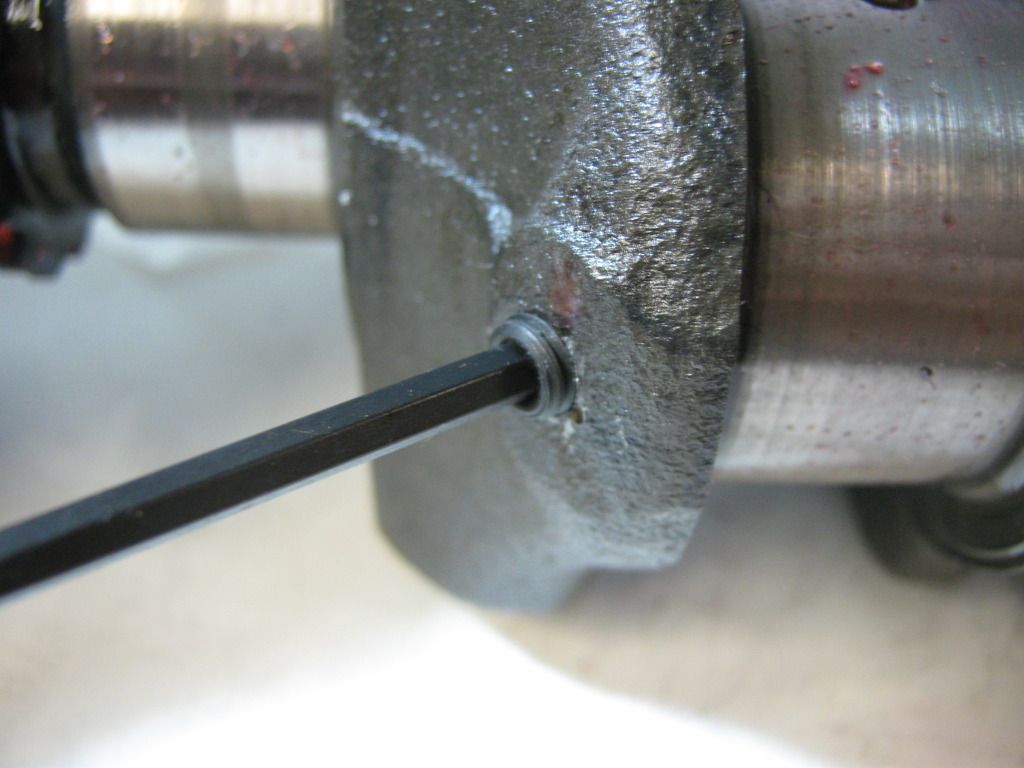

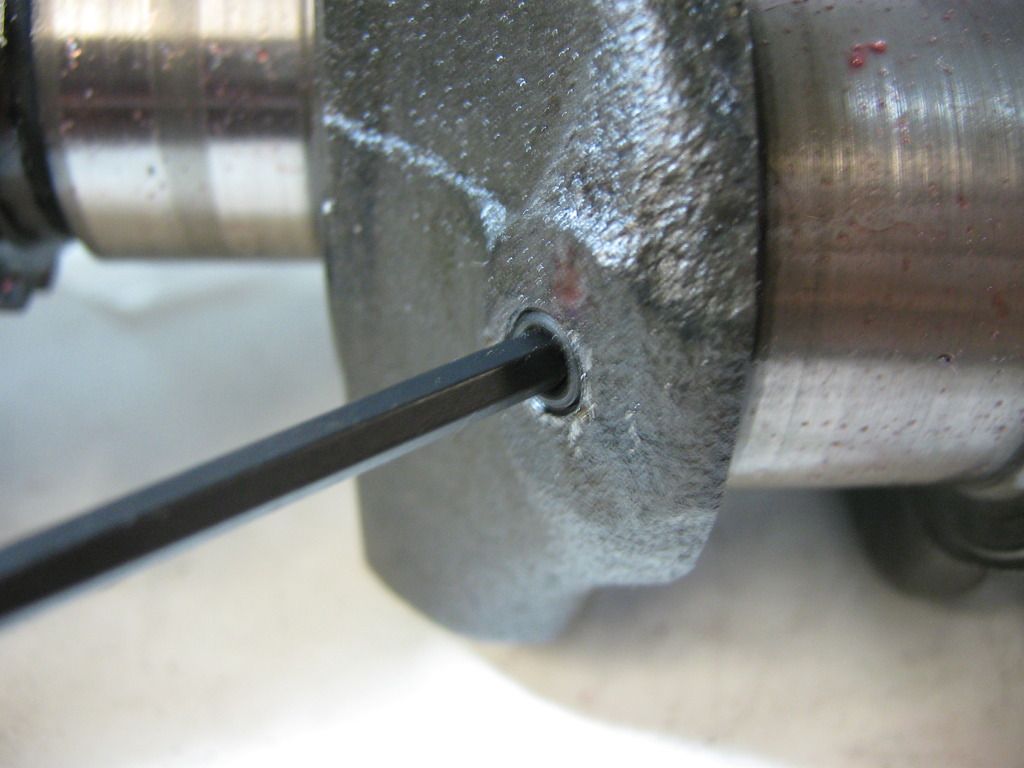

7. Now your getting close to depth so try your set screw you want it to be tight and bound up and still be proud of the surface.

8. Go back in with the tap and slowly go 1/2 a turn deeper with the tap clearing chips as you go outlined in step 6.

9. try set screw again you want it flush with surface. if its still proud repeat step 8. The whole idea here is to get the bottom threads on the grub screw to bind in the starter portion of the taps threads, this creates a mechanical lock

10. After your done and have the set screw flush with the crank and locked or binding. Remove all the set screws and clean the hell out of the crank passages, any drilling or tapping chips left can be picked up by oil and washed into the bearings which would be all kinds of bad !!!

11. After the passages are clean make sure your new threads are clean of oil and grease. Use some lacquer thinner or acetone to do final cleaning.

12. Apply red loctite to grub screws and tighten them down.

13. If desired stake the head of the set screw this will provide 3 different locks to keep them in place.