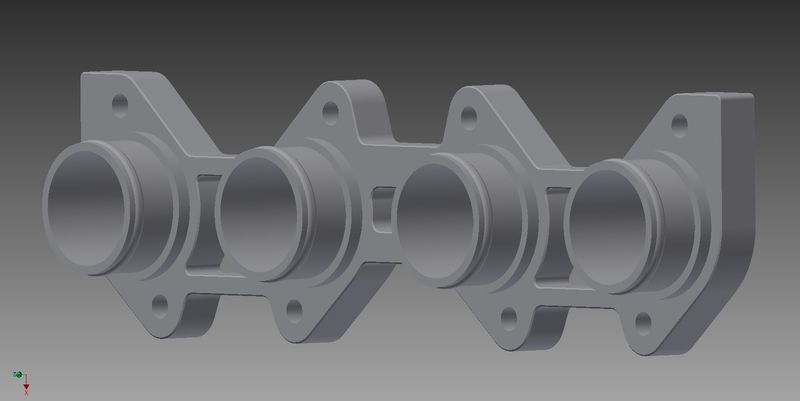

I am running a setup of Weber DCOE 40's on a custom made manifold. This is my first version:

I noticed that making the reduction from 40mm to the stock intake on a 750 will be much harder to find a hose to accomplish this. Not only will it be harder to find but the rough transition in size might introduce some unwanted turbulence. So the reduction will have to take place inside the spigot so the stock boots may be used. So I'm asking what kind of profile would work best in my situation. I've got one design that utilizes the bell shape of a velocity stack, another that is just flat chamfer, and one that uses the theory of a throttle body spacer which would include a spiraled groove through the spigot. Any input is appreciated.

Haha...the "spiral groove" comment brings back the memories of one of my favorite Product Tests of all time: the [in]famous "Tornado Vortex" intake path adapters for the KZ1000, I think it was in 1974? These were a set of 4 spiral vane sets that were slipped into the intake tract, with instructions that you "...must rotate them individually until the air hits you mainjet (sic: needle jet) at the right angle to make it atomize the fuel better...".

Aside from the fact that this could take all Summer on a typical 4-cylinder bike...the rider-journalist reported that after installing the set at the manufacturer's "...advised beginning rotation position..." (picture was included), he noted that after having to recharge the bike's battery for lack of it starting afterward, and his related turning them 15 degrees to another position to let the bike start, when he subsequently shifted into 2nd gear at 6000 RPM the engine flat died during the shift.

!

So, he restarted the bike, rode it back to his garage, removed and threw out the Vortex Adapters "so they won't get used again" and wrote a scathing article entitled, "Finally, high performance adapters for your wastebasket".

Ouch!

Normally, a bell-shaped adaptation to either a larger or smaller orifice is the style that produces the least troubles. This is due to the irregular surface shape of such a profile, which provides NON-formation of deep laminar zones along the surfaces of the pipe. The constantly nonlinear profile causes the air, which likes to be linear if possible, to always be turning gently instead of rolling, as an edge or blockage would cause.

To test this yourself to "see" it, turn on a water source (like the kitchen sink) and let it fall over things like a spoon, small plate, or other utensils. Air acts much like slow-moving water will, across the surfaces you will introduce into the flow. This should help you visualize the profiles you will need.