A little farther today. The Showa shocks cleaned up nice.

Exhaust removed for frame cleaning and polish. Speaking of polished "off" I need another bottle.

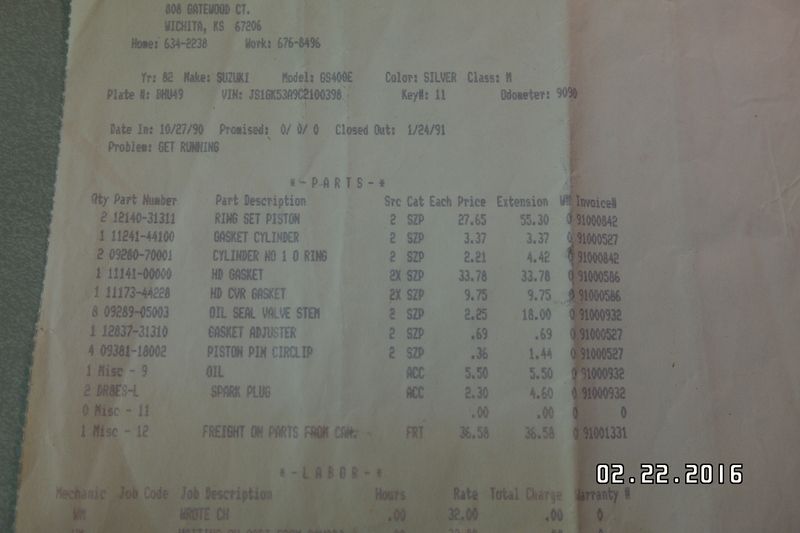

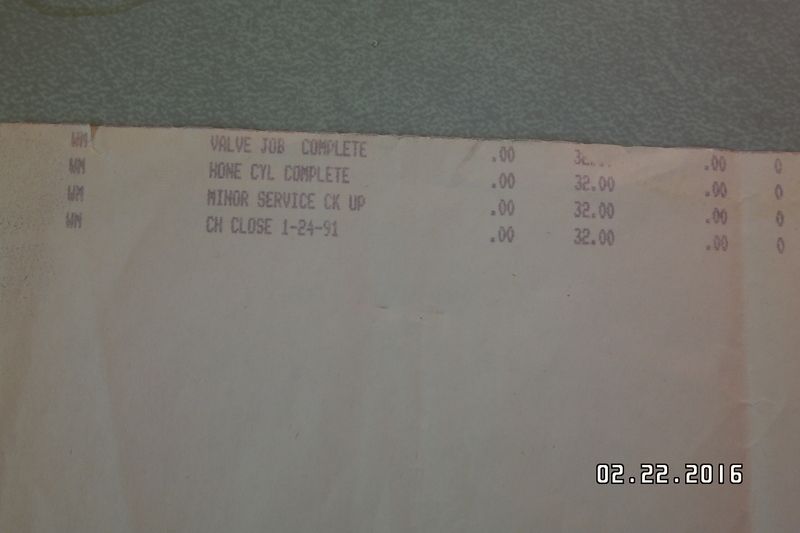

In hindsight I wished I would of asked about this invoice. As you can see it's a whole new top end including a valve job. If the speedometer is working and the invoice shows the mileage it equates to 1311 miles ago or 1991.

Page one.

Page two.

Also working on a complete R/R replacement which will need rewired. I'll post that info as I read up on it.

Cheers!