I acquired sandcast engine E1490 several years ago with the intension of repairing damaged cases and getting another sandcast engine back together. Unfortunately, there are six areas that need to be addressed. If it wasn’t for the fact that they’re fairly early, legitimate cases I wouldn’t waste my time. Here’s the number.

And the casting dates.

What happened was the outside bearing on the final driven shaft failed (probably under load) causing the final driven gear to crash into the rear of the crankcase. I understand this wasn’t as common as the chain break problem but it must have happened often enough for Honda to change this bearing on the K2’s.

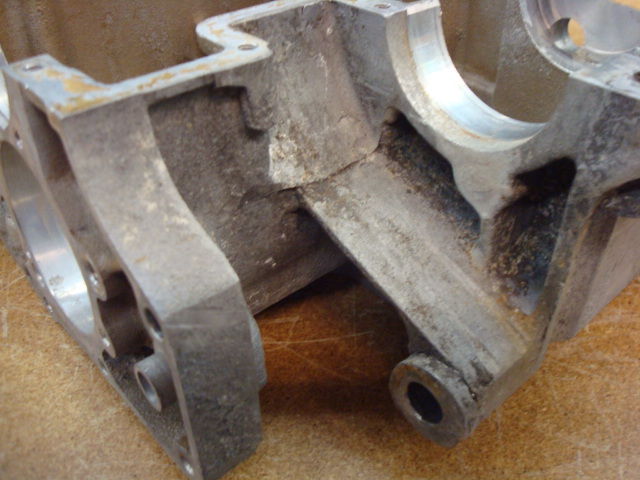

This caused the crankcase to crack and the bore for the inside final drive shaft bearing to get damaged. Here you can see where the gear hit the inside of the case and the damaged bearing bore.

Here is the crack on the outside.

A closer look.

Fortunately it does not have any chain break damage.

Apparently then, after it was damaged, it must have sat around for a while. Long enough for the oil filter housing mating surface to get corroded. I’ve seen that before on E100.

And a close up.

Then someone finally decided to try to repair it. They should have had someone who knew what they were doing. The stud on the front of the engine between cylinder #3 and the cam chain tunnel is broken off.

Also the stud hole is broke out on the front of the engine on the corner by the #4 cylinder.

Finally it appears that the “mechanic” used a sandpaper disk grinder to remove the cylinder base gasket.

So I have some ideas but I have some questions too.

Should the crack be welded on the inside, outside or both? It would be nice to try to match the surface enough so the repair isn’t very noticeable.

I think the bearing hole can be cleaned out with a boring tool on the mill.

I need to clean up the oil filter housing surface to see how bad the pitting is but I can put that on the mill like I did for E100.

It would just be nice to find an easier way.

The broken stud can be removed by EDM or drilling. The other hole I think will take some welding then re-drilling and tapping and counter boring. Does anyone have the dimensions for the location of the studs? I think someone here made billet cylinders; they would have to have the dimensions.

The sanding damage has me concerned. I need to check how flat it is. It’s much worse than the picture shows. How much material could I skin off the surface without causing a problem? How about smearing some JB Weld on it to fill in the gouges then machining it flat?

Like I said, I think it’s worth the effort and if any of you have any good ideas for some of these repairs I would certainly appreciate hearing them.