Wow, has it really been over two weeks since my last post? How time flies when you're getting old, and have more projects than sense. Did I mention I have now got 2 x K2's to build (one of which will get a 970cc hotrod engine) and 2 x K1's, in pretty much standard trim? I have my 1970 K1 to do, and had a leftover 1971 K1 frame, so found a very close engine to go in it, so that'll be collected from Brisbane in a big wooden crate this week, and I should have it very soon, Covid-19 willing.

Anyhoo, back to the horrible K2. Dion decided that he couldn't be bothered fixing the rusty frame so took it on himself to find a good frame, which he did here in Melbourne, and as he lives so far away, I collected it for him. He'll come pick it up soon and take it away for paint. Suits me.

I kept scrubbing and degreasing those ugly cases, and whenever the sun was shining, hit them up with some "Ceramic" engine enamel in "as close to as I can be bothered" to the original color. Looks a tad better.

Before:

Horrible CB750 K2 18 Apr 2021 9b

Horrible CB750 K2 18 Apr 2021 9b by

Terry Prendergast, on Flickr

After:

Horrible CB750 K2 28 Apr 2021 1

Horrible CB750 K2 28 Apr 2021 1 by

Terry Prendergast, on Flickr

Before:

Terry’s Horrible K2 Engine Autopsy 16 Apr 2021 6

Terry’s Horrible K2 Engine Autopsy 16 Apr 2021 6 by

Terry Prendergast, on Flickr

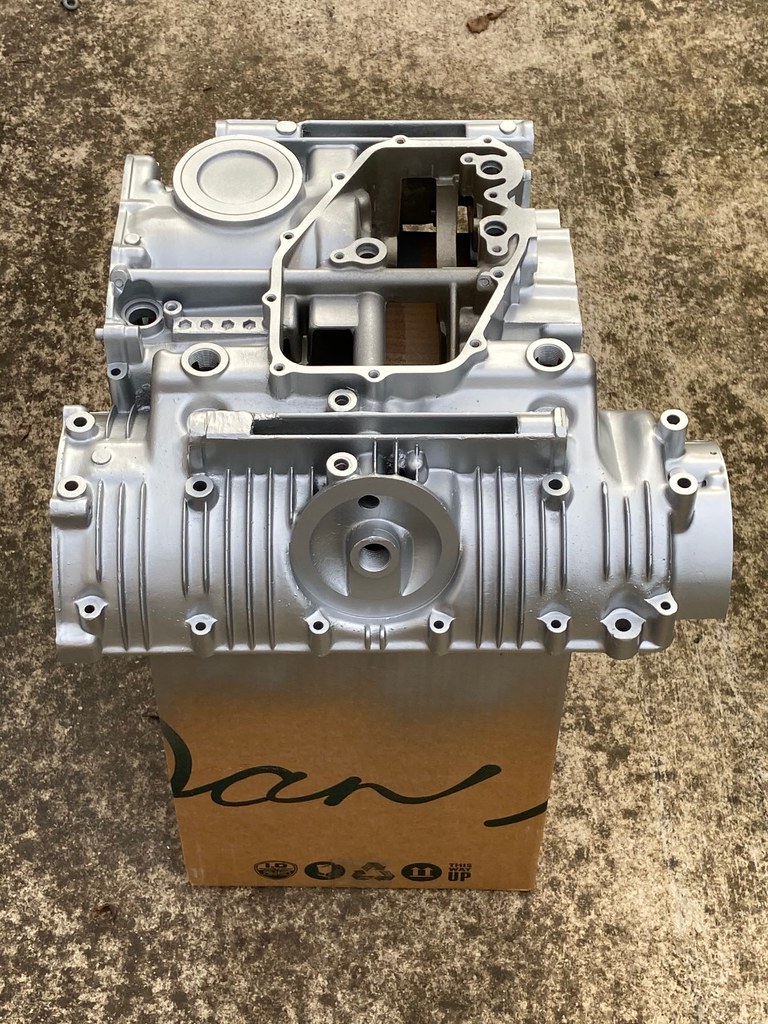

After:

Horrrible K2 weekend 2-3 May 2021

Horrrible K2 weekend 2-3 May 2021 by

Terry Prendergast, on Flickr

Yesterday after work I used some "Plastigauge" to measure the main bearing clearance, torqued the cases down and then tonight, being freezing cold and wet (what a change from the warm sunny weekend) I undid the bolts, separated the cases and measured the plastigauge and was 'rapt that the clearances were all around .001-.0015", which is perfect, the factory manual allows up to .003" before the bearings need replacing, but these ones are fine, and have saved me some much needed bucks, as I'm bleeding money on bike parts at the moment, and (supposedly....) this is a "Budget Build". The big end bearings are great too, so more moola saved, to be redirected to shiny stuff that can be seen.

I've had the cylinder block in and out of the ultrasonic cleaner, and along with some wire "bore brushes" that mount in my little DeWalt rattle gun, I've cleaned all the corrosion off the fins, and it's silver again.

I heated them up in my industrial oven to 400 deg F, and the old rusty sleeves fell out. Sadly some oil that must have been trapped betwixt the sleeves and the block came out too, so back in the ultrasonic cleaner it has gone.

Horrible K2 engine rebuild 5

Horrible K2 engine rebuild 5 by

Terry Prendergast, on Flickr

But that's OK, tomorrow I'll shove all the guts back in the bottom end and (hopefully) bolt it all back together, then start thiinking about boring out some sleeves to 65.5mm (849cc) to suit my Cyclex big bore kit. Should be good!

Horrible K2 engine rebuild 4

Horrible K2 engine rebuild 4 by

Terry Prendergast, on Flickr