Time for an update!

As this story left off I had my master cylinder cleaned and reassembled and my brake hoses cleaned. Next step was to paint my caliper and top triple tree that will one day go on my bike. This was my first time doing any real painting so I wasn't expecting perfection. I shot the parts with a few coats of primer, sanded with 400 grit till things looked nice, and the shot a few coats of gloss black. I guess I didn't sand and prime as well as I thought because I ended up with some "orange peel" effect on the parts. I used the caliper the way it was because it didn't look too bad and I was trying to quick get the bike ready for the VJEMC show. I will redo the triple tree in the future.

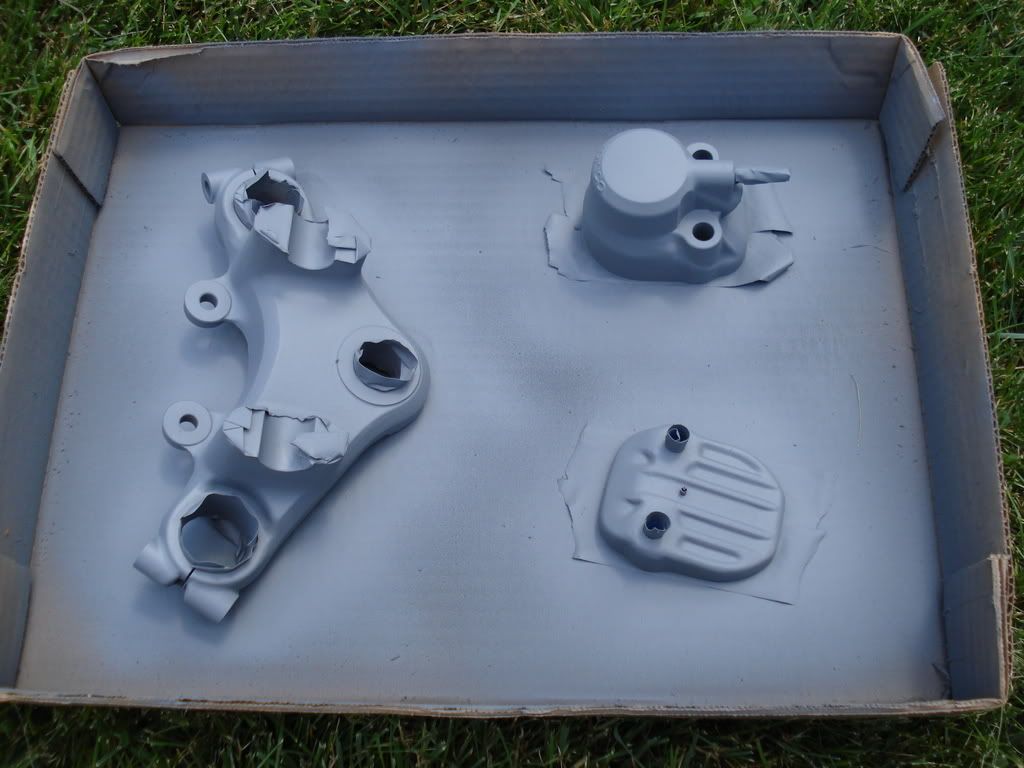

Primed

Painted

Since I was doing all this work to the front brake I decided to add new brake pads as well, just for good measure. My brake piston was also pitted so I bought a new phenolic brake piston from whatshisface (can't remember his name) on the board here that sells them.

And so began the caliper assembly. The oem brake pads I bought wouldn't fir into the caliper so I had to grind them down until they fit. I greased them with some kind of stinky brake parts grease from auto zone. Everything went back together just fine. I connected up the brake hose and brake switch so that I could begin bleeding.

For brake fluid I used a generic dot 3. For bleeding I used a vacuum bleeder that my dad bought some time ago. After reading here about all the different methods and theories of brake bleeding I felt confident that I could do it successfully. I tried nearly all of the methods (turning the handlebars different ways, just letting it sit, pumping the brake lever in small increments...yada yada yada). All of these produced bubbles either from the caliper or the small hole in the master cylinder. As time went on I finally got to a point where I wasn't getting any bubbles from the small hole in the MC or the caliper. The problem was that I was getting bubbles from the large hole in the MC. I consulted the forums and found that this was not normal. No matter how many times I pumped the brake lever I would get a continuous stream of large bubbles out of this hole. None of this made sense to me because, according to where the hole is, this would mean that the seal closest to the brake lever was leaking. The thing was, I didn't notice and brake fluid leaking from around the brake lever. Another thing I noticed was that, along with the the bubbles coming out of the hole, I was getting black cloudy fluid. This puzzled me because I know I cleaned everything quite thoroughly so I doubted it was leftover debris in the system. After trying to bleed the system even more I figured I would leave it overnight to see if things improved.

The next morning, things hadn't improved. But on the plus(?) side, there was a small amount of brake fluid that had leaked onto the floor, so at least I knew what the problem was. So I drained the brake fluid and tore the MC apart again (oh joy!).

On a side note, when I took the MC apart the first time I used a needlenose pliers to pull the rubber boot off the piston. The 35 year old piece of rubber didn't rip or anything so I saved it. When I reassembled the MC I used the new boot that came with the kit. Now when I take the MC apart for the second time the BRAND NEW rubber boot rips apart right away!

So as I am examining the MC parts I notice two things:

1) There was some sort of paint/coating on the MC piston that was coming off of the part and onto my hands, as if the brake fluid was eating it off. It was also black so this was where my cloudy brake fluid was coming from.

2) On the "vertical" section of the piston where the seal closest to the brake lever sits against, there were tiny spots of what seemed like Welding slag. I guess it's just something I missed when I was putting the thing together. That slag must have prevented the seal from doing it's job, thus letting bubbles into the MC and brake fluid out. Also, the outer edges of that seal seemed slightly torn but luckily my MC rebuild kit contained an extra.

Evil slag of doom:

After cleaning things up again, I rebuilt the MC for a second time (doubly joy!). I cleaned up and reused the old MC piston which amazingly did not have any slag stuff on any of the sealing surfaces, or anywhere for that matter. I also cleaned and reused the 35 year old rubber boot that somehow doesn't rip.

Moral of this part of the story: I do not recommend buying the MC rebuild kit from Sirius Consolidated.

I got my MC reassembled at around 1:30 AM the morning of the bike show. I went to bed and woke up at 5AM so I could get things back on the bike and the system bled. I was a man on a mission and there was no way in hell I was missing that show. I bled the brakes as best I could, right up until 10AM when I wanted to leave. I'll admit that my brake lever wasn't perfectly firm, but it was a vast improvement over what it was like before I started messing with it. And guess what else? No more bubbles came out of the big hole in the MC. Imagine that.

Off I went to the bike show. You can read more about it and see pictures I took here:

http://forums.sohc4.net/index.php?topic=36939.0 As I was riding to and from the show, my front brake began to squeak. Not too bad, but still there. Unfortunately as time went on the squeaking got worse and I was riding the bike less and less because of it. I had just spent all that time (and money) working on it and I just wasn't in the mood for more trouble shooting. I just wanted to ride and I couldn't. It got so bad that I could hardly use the front brake to maneuver the bike around in my garage because it was so loud.

Fast forward to a week ago. I'm moving back into my house for college and one of my new roomates comes riding in on a fixer upper yamaha 750 genesis. We start talking bikes and this finally gets me the urge to work on my bike so that we could go for a ride sometime.

I searched the forums for ways to stop brake squeal. I tried two different things at first. One was a product called CRC disk brake quiet. It's a thick substance that you spray on the back of the brake pads that is supposed to dampen any vibrations. Simultaneously I tried another trick which is to cut grooves in the brake pads which is supposed to change the frequency at which the pads vibrate. Long story short, neither of these worked for me.

Last saturday I decided to try one more trick that I probably should have done a long time ago, greasing the caliper pivot bolt. I was hasty in my wrenching and one of the front fender stays scratched up my paint on the caliper, but oh well. Initial tests were promising because I could now move the bike around in the garage without it squeaking. But as soon as I hoped on the bike to go down my driveway and a quick test ride, the squeak was deffinitely still there.

On sunday I decided enough was enough. I cleaned the crud and rust off of the old brake pads and put those back on. They never did squeak and still don't. They have plenty of pad left on them so I figure I have nothing to worry about. It was interesting to note thought that when handling the pads, the old pads a noticeably softer than the new ones. I wonder if that the way they always were or if they softened some over time. I took a test ride through some drizzle down to Fond Du Lac and back and no squeaks at all. As forum member johnie said to me in an email, it just goes to show the old addage that if it ain't broke, don't fix it.

It's supposed to be a beautiful week and I now I intent to start enjoying the fall riding season.