Hi All,

It’s been too long as usual. Different projects in the way.

Over the last couple of weekends I have thrown myself into the 450 project.

The bike has been stripped down and I am ready to remove the engine and prepare it for complete disassembly.

As you can see the chain sprocket area is a mess. But it will be dealt with later on.

I took as much off the engine as I could to lighten the load to get it ready to put into the engine stand.

The engine stand was purchased off of Ebay, and I have a second cradle for CB750 engines that fits into the base (you can see it hanging on the wall in the background). The tool cabinet fits under my workbench, so I needed to make sure the surface stays flush when I am not using the engine stand. To secure the stand to the base, I drilled out holes for 3/8” threaded inserts. The bolts are 3/8” X 1” and the stand is very sturdy on the 1” base of the work surface. Later on, I had to crank on some bolts and the stand worked great!

Here is the engine in the stand, secured by the mounting bolts that hold it to its frame. It’s a bit high, but I think it will be good for getting to the bolts underneath.

As we were maneuvering the engine to the stand, this fell out…

It holds the lowest cam chain guide on the engine. As it turns out, it was lost the last time the PO was in the engine… I only hope it was benign as later pictures will show.

Now that is a naked bike!

Removing the Cam Chain Gears and followers from the head.

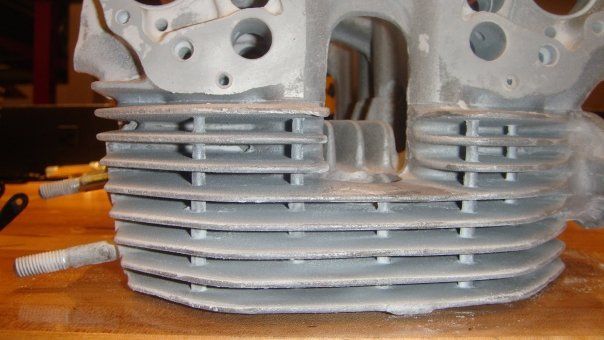

The Cylinder is off

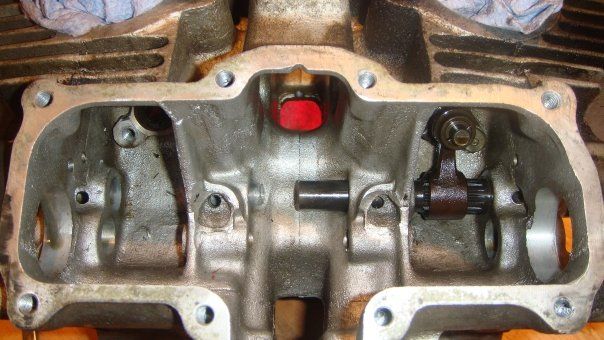

The Intake Cam and rockers

My buddy Lyman broke the drive train. It was a B!7(!-!

A great tool – the Motion Pro Chain Breaker. We did the Cam Chain and drive chain with it.

Meanwhile, here is the exhaust Cam…

The Rockers! Cb450’s don’t have valve springs. They move against Torsion Bars.

After a bit of a struggle, and a little easy banging with a screw driver and mallet… one side is out!

Now for the valves…

My Tusk Valve spring compressor. The Clymer manual will tell you to remove the torsion bars and then the valves. I promise you it’s much easier to remove the valve first! Much safer as well…

Using the 23mm attachment, and making sure the other end is secure in the dead center of the valve face, I slowly applied pressure to remove the holders.

Empty Head! (Just like mine!)

At this point, when everything was out of the head, I hit it with some gunk to get the years of neglect off of it. Worked Ok…

However, I figured my Soda Blaster could do much better.. and it did.

The Cylinder as it came off the engine:

More to come…