for those that dont know this trick , when lapping valves , mark the seat of the valve with a dry erase marker to check the contact surface. then you know how much to lap

before

after

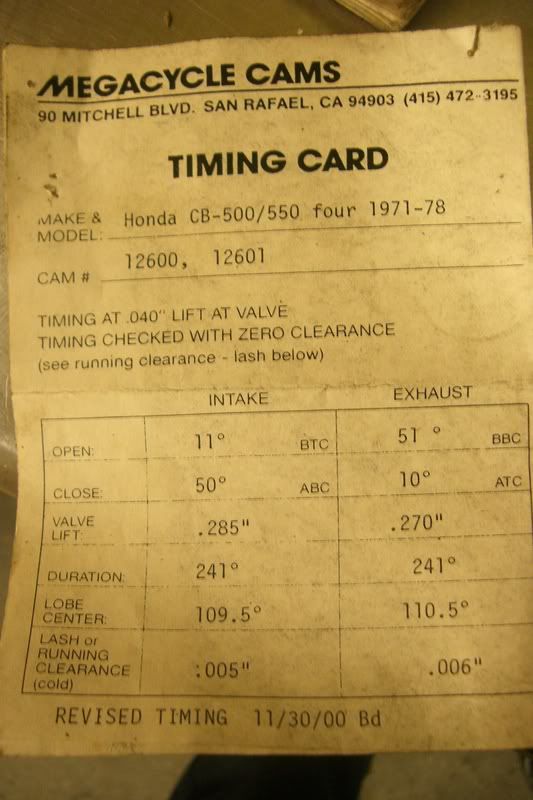

got my cam degreed in , but i did it kinda half assed (but not really)

once i figured out were true TDC was, set the valve at .040" (zero lash). checked the wheel ..... it reads 11 degrees ...i think to myself "there is no way i got that right on the first try"

i have a slotted sprocket , i just set the cam at the stock mark, put the sprocket on and tightened it, BAM first try

i checked it 3 times to make sure ...guess i just got lucky. or i've had this motor apart so many times my subconscious just knew where the sprocket needed to be

either way it's a done deal , ported head is on , cam is timed, valves are set. now i'm got back out and put the carbs back on

check out my high class dial indicator holder,

i cant believe i got it on the first try "oh he's a little impressed with myself , don't mind him"