You know you've been through a lot when you say to yourself, "eh, that's an easy fix.. I just have to split the cases."

I got the engine together up to the head last night, and just before leaving found a crack in my top case... yes, a crack. I didn't have the heart to tear back into it last night, but believe me I thought about it a lot. Sometime about 2am, I realized what had happened: the mainshaft needle bearing had rotated when I was putting the bottom case on, and the alignment dowel had pushed through the case when I bolted it up.

Still, I was pretty certain I knew this was what had happened and sure of my solution, so this afternoon I continued with timing the cam and buttoning up the top end before I flipped the engine over and... thought to myself, "eh, that's an easy fix.. I just have to split the cases."

Sure enough, this was the problem. I pushed the split piece back into place, JB welded it from the outside, and for good measure put a dab of 1194 on the bottom of the alignment dowel and put it back together. This dowel shouldn't see any pressure, nor is there really any oil behind it, so I'm pretty sure the fix should work. The whole operation problem cost me 45 minutes.

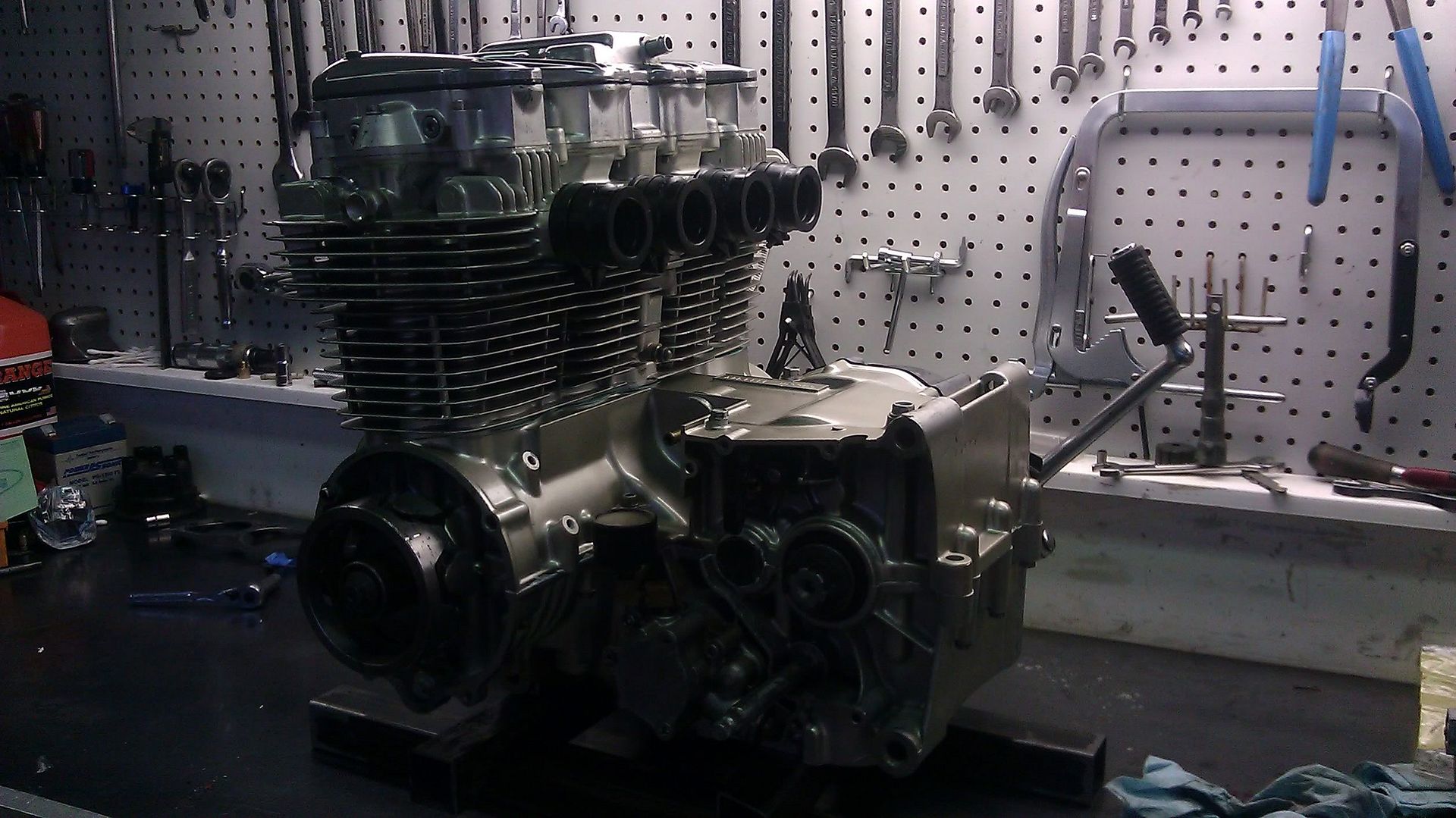

Anyway, here it is back together. Just grabbed a 22 of IPA and am about to put it in the frame. Can't start it until tomorrow when the JB weld has cured, but it's still a huge step forward.