On a whim I thought I'd like to see how my bike sounds with no baffles in the pipes, so I

yanked mangled them out. It sounded good at idle, burbeley and echoey, kinda like being surrounded by Harleys. It was also amazingly annoyingly deafeningly loud. Now, I've had this idea for many years to use a glasspack type muffler on a bike, but with a flat end so it doesn't look like a glasspack. I cut down my existing pipes, lopped off the inlet and outlet of the muffler, and chopped it in half. I welded it on and it sounded a little quieter, but I still needed the ends capped off. I rode over to a friends house (a mile maybe) to make the parts and some of the fiberglass had fallen out. I looked and couldn't find it. I made the parts and never put them in. After a few weeks I got tired of it as the empty mufflers weren't any quieter. I looked on Cycle X's website and saw several options, one being the used $200 pipes and the other being the tri-y pipes, which I had wanted. I also wanted to try the power-arc ignition, and what the heck, lets throw a cam in it for $100 more. I got on the phone to Cycle X and ordered the power up kit 2. the next day I cut the one piece of muffler fiberglass I had and cut in in half, putting one piece in each muffler and capping them off with the parts I made weeks before. That made a huge difference, if I had done that earlier I probably would not have ordered new exhaust.

Backstory over.

The victim in the lab.

A before video of the exhaust for comparison.

I backed into it and knocked it over earlier this summer so everything in the back end is bent and crooked.

I hope I'm not required to post pics of taking it apart. I'm sure you've seen stripped down frames before.

Once I got the motor out with the "lay it over" method I had my brother help lift it to my work table. I put some 2.5 inch (63.5 mm to everyone outside the US) square steel tube under the motor where the motor mount bolts go through. It's nice and flat and holds the motor solid. My brother took the initiative to clamp it down, I'm glad he did because I put some force to it and it never moved. The valve cover gave me a little trouble, but I got by with a phillips screwdriver bit and a hammer. The bit went in the screw heads and I hit them with the hammer to knock them loose. It worked pretty good. the little valve adjuster covers were something else as they seemed to be on very tight. A 6 point 17mm socket got them out without too much fuss. Now the motor is on the slab topless.

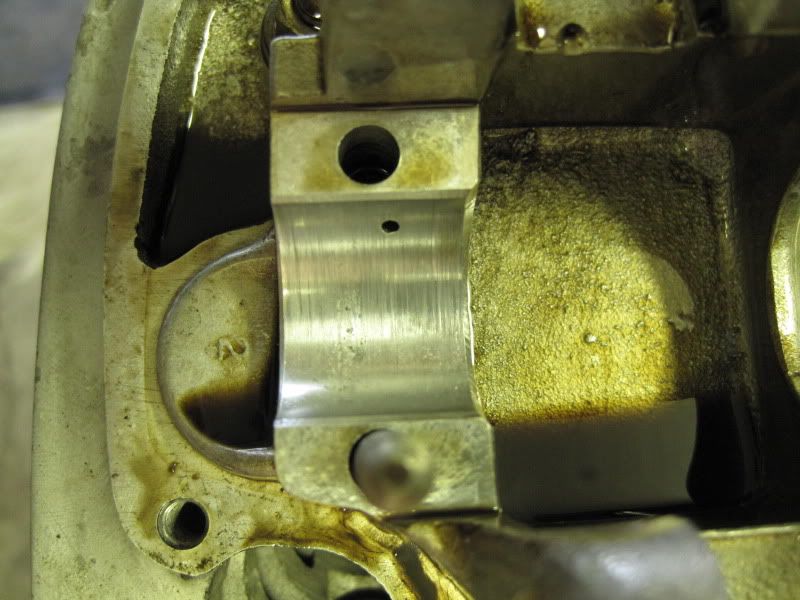

I wasn't sure just which bolt had to come out to get the cam out, and it turns out that all of them do. So, a 10mm socket and then an 8mm socket got the rockers out and the cam free. I made sure to keep everything in the order it came out. (except for some of the bolts) Looked nice and clean.

I should buy a cheap camera so I don't get my good Canon greasy.

Here are my cam "bearings", from 1 to 4.

Once the cam was in I decided to put the rockers on before I set the timing on the cam. I found out that doesn't work. My exhaust valves were hitting the pistons. Disappointed, I posted here and one of the responses was about cam timing. I went back out, pulled all the rockers and set the timing. There was no problem after that.

Here is where the magical ass rape fairy came to stay for awhile.

I looked at the manual on Honda4fun and it said to torque the cam tower bolts to... whatever it was equaled about 110 inch-pounds. Once those bolts were torqued (which didn't seem like enough) I went to torque the little rocker shaft bolts. There is no torque spec for those, so I tried to get to the 110 inch pounds like the others. I broke one, twisted the head right off.

I figured since I still have one in there, and the broken part isn't coming out it would be ok.

Once the rockers were in I set valve lash, and then put the cover on. I had just gotten the cover on (including valve adjuster covers)when I realized I had forgotten the thrust washer on the end of the cam. So, off came the cover, and in the process I tore the new gasket.

Now, thrust washer on, cover on, torn gasket patched with rtv, and what do I see? A cam sprocket screw. [Ralphie Parker]Fuuuuuuuuudge.[/Ralphie] Once again off it comes. How many screws are there? A metric #$%* ton it seems when you put them in and out 3 times a night.

While the motor is sitting on a table I thought it would be a good idea to unbolt the spigots since the tri-y pipes don't use them. 7 out of 8 screws came out, the eighth broke my philips bit. I'll have to borrow an impact driver.