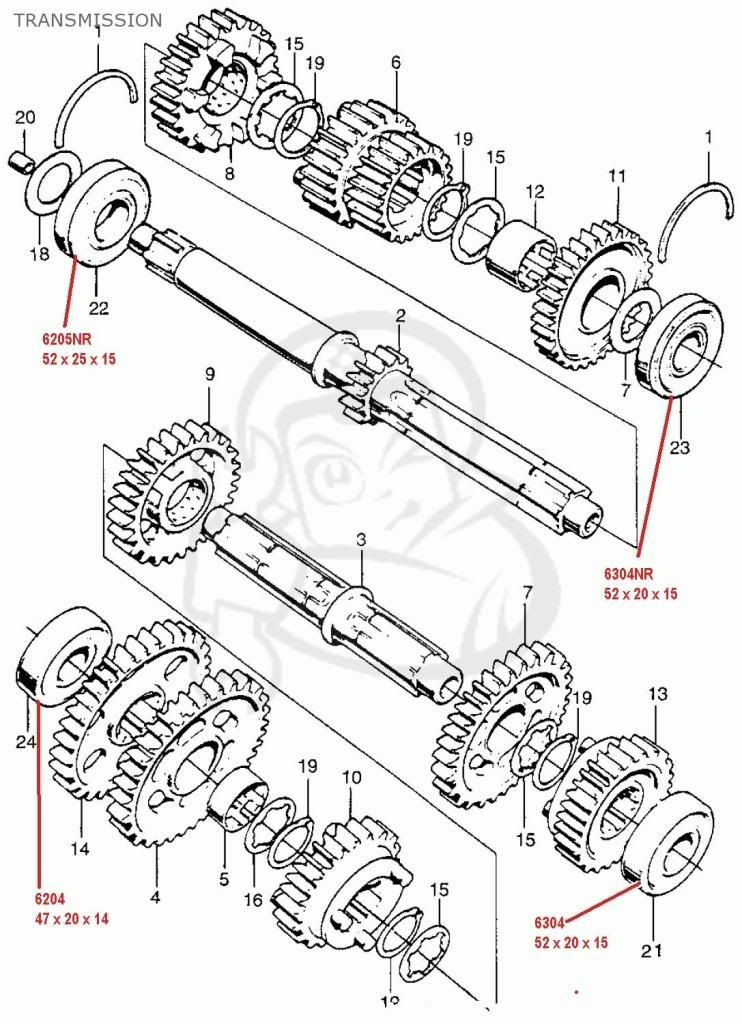

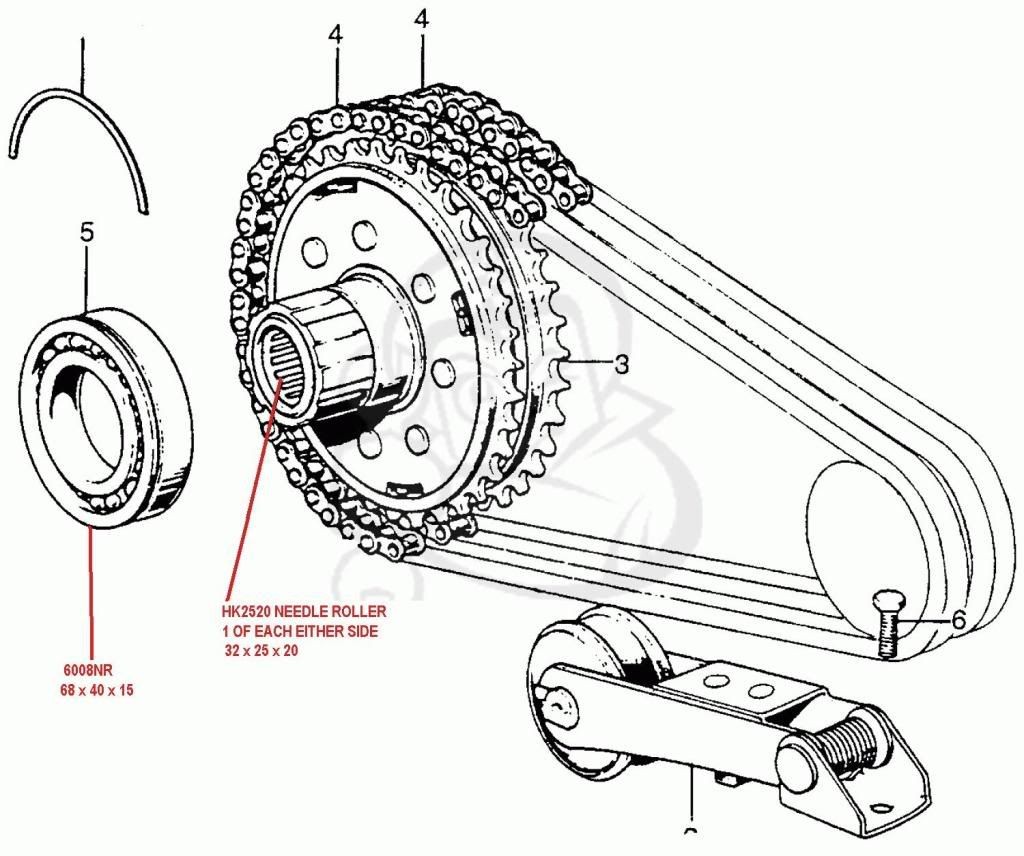

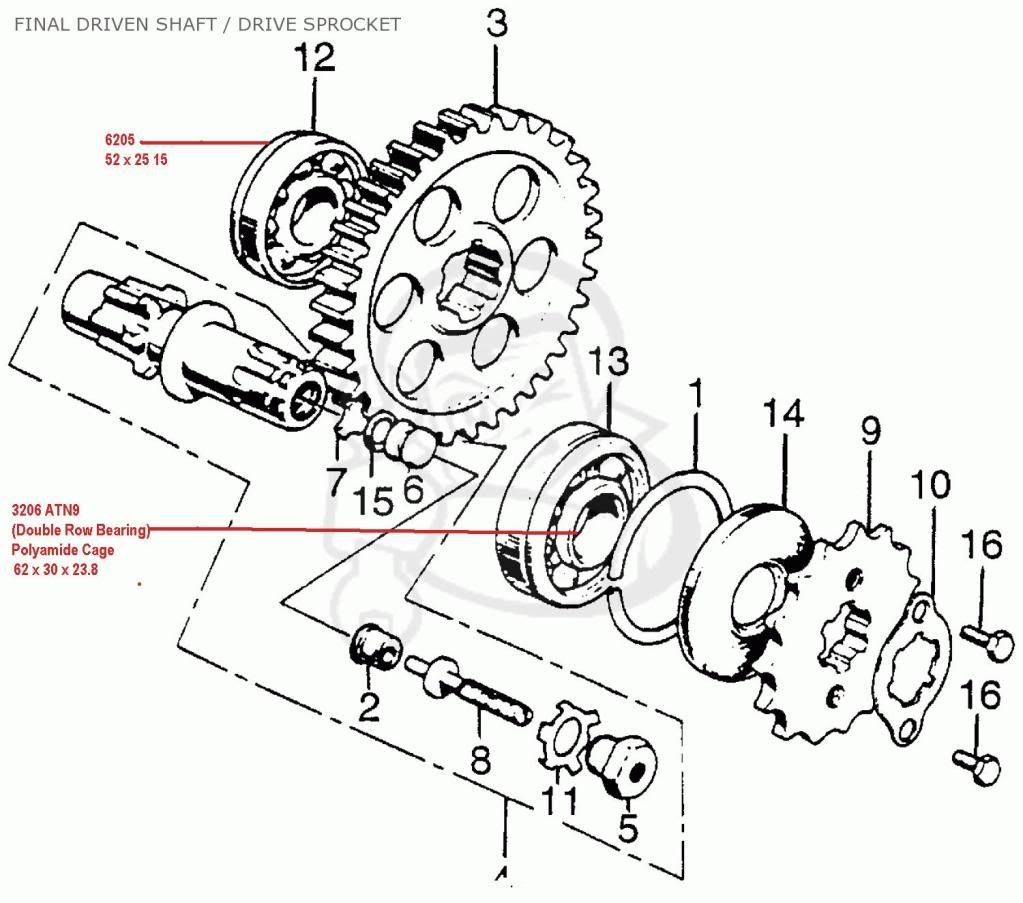

Can't you help with the grooving procedure but here are the bearing part #s that I've used previously.

The grooves are the correct width.

These were purchased from SKF Bearings and the numbers should be recognisable by other suppliers.

(I'm assuming these are for a 750)

Mick