Hi all. It's been nearly a month, but I have not been idle! The rear brake set up has been a right royal pain in the arse. As those of you who have modified bike parts from one model to fit another bike part, the rational train of thought would be to marry the two different model parts to try and come up with a usable solution. I attempted this for the rear brake assy. Quick recap. CB900 (circa 1980) swing arm, CB750f2 (1992) rear wheel and disc. Now the CB900 uses a brake calliper bracket with a torque arm and the CB750 has a calliper bracket that has a slot cut in it that fits over a guide mounted on the swing arm. Because the new swing arm has eccentric adjusters I couldn't weld a guide to the inside of the swing arm because of the "arc" pattern of the chain adjusters, they do not just move in and out parallel to the swing arm like the 750. I hope your getting this!

I bought a late model CB900 (read 2 piston calliper) rear brake assy and tried that. I should have done a bit more research on the diameter of the 900's rear disc, it's nearly 12". Needless to say the smaller 750 disc was miles off the calliper. I looked into getting a custom, one off, rear disc made. No joy. I looked then at "shortening" the 900 calliper bracket to fit the 750 disc, it would then foul the rear shocks! The pic below shows the difference in size.

I trawled through loads of pics of projects to try and come up with a solution that wouldn't cost me the earth. After about 10 pints of lager it came to me! I cut some aluminium and welded it into the slot of the 750's calliper bracket. I then rotated it anti clockwise about 90 degrees and the bloody thing only slotted right onto the 900's torque arm! Result. I then pushed the steel sleeve out of the 900's bracket, drilled and loctited it into the modified 750's bracket.

I still have to trim and drill the bracket to smarten it up but it looks like it'll do the job. I'm thinking of mounting the electric pick up for the speedo here too as not to have a cable running up the front forks.

You only ever see callipers either directly on top or underneath the discs so I'm hoping there's no engineering/stress reason why it can't be mounted where it is.

Some of you may have noticed in a previous picture of the bike that it had grown a set of carbs and a battery. I thought I best try and get it running if I'm doing all this work. God bless the old dear. I just charged the battery and pushed the rebuilt carbs ( cleaned and float heights set ) on with the tank full of stale petrol and she fired up after a couple of cranks. Sounded and ran like a bag of #$%*! I found two things primarily wrong. There was no lock nut on the cam chain adjuster and one of the carb insulation rubbers had a big split in in. New carb rubber from

http://www.davidsilverspares.co.uk/ £16 and a nut for the adjuster out of a spares box, free. Try again... beautiful. Surprisingly crisp revving.

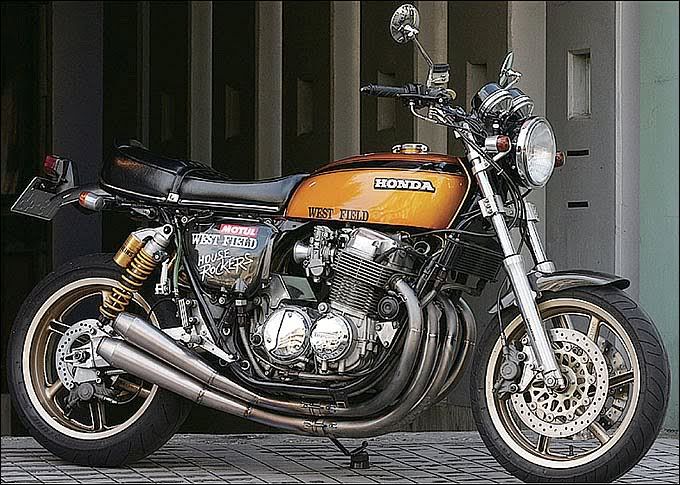

If any one can remember my inspiration photo you'll see the bike has bell mouths or velocity stacks on the carbs. I spent ages looking for a supplier in the UK but drew a blank. Then I came across this site and I just could believe how little they wanted for a set. They even do them in copper!

http://www.steeldragonperformance.com/index.html

I realise jetting the carb for these is going to be difficult so if any one has any experience re-jetting, please share your knowledge.

Right what part do I tackle next!!!!!