Here goes nothin! I'm trying to build a good looking cafe seat that can go two up (my girlfriend complained too much when I told her I was putting a solo on...) and because I'm a poor college kid, I can't buy a nice seat; so I'll build one

So I started messing around w/ some stuff I had around (conduit and a couple pieces of flat bar) and I liked how it looked so I kept it.

My buddy was supposed to weld it together for me until I told him it was galvanized

But I had some rivets so I just riveted it together. It's pretty rugged really.

Then started forming for fiberglass. That "indent" where the foam/cardboard meets the metal would come back to bite me. "I'll just bondo it" haha

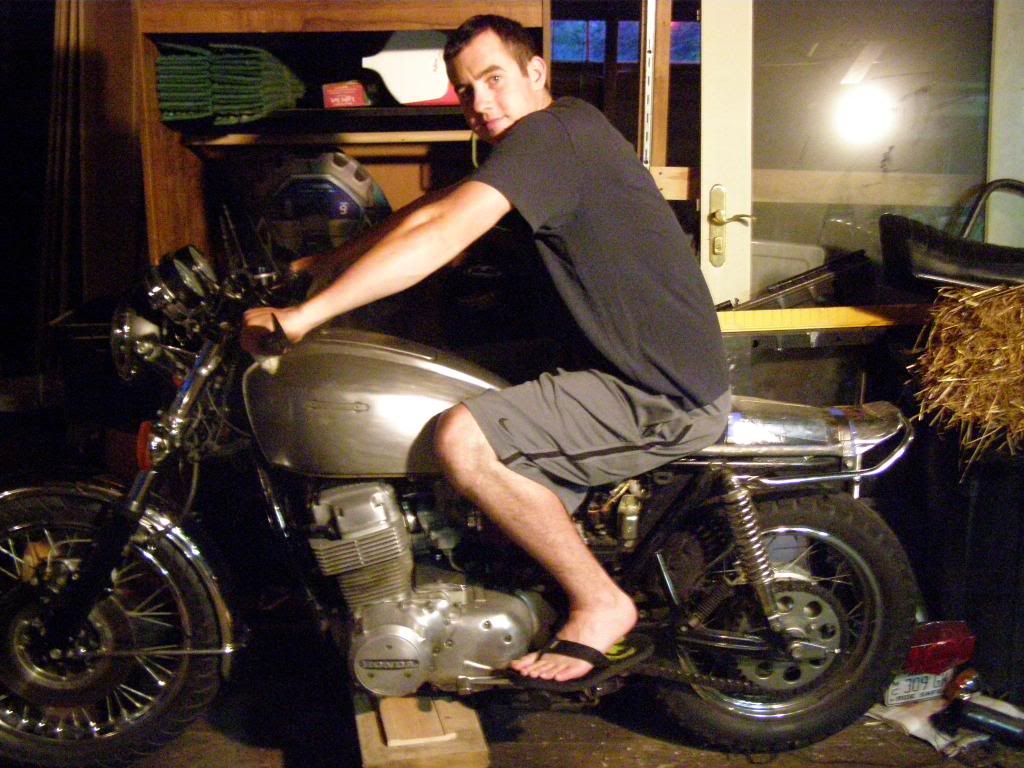

And a mock up pic on the bike. Haha ya I work in flip flops

I didn't take any pics after I decided it was too low and added a layer of 1" rigid insulation on top. Here it is after my first ever attempt (so give me a break

) at fiberglassing. about 3-4 layers of mat, grinded it down (sry no pics) and added one more layer of mat.

It's pretty damn rough but I already shaved the stock seat mounts and lock so I'll stick with it.