So, the fins were chipped and broken

The Pistons were standard.Bores were shiny but still serviceable.

Luckily a spare block came with the block. As mentioned earlier the PO admitted to snapping a camshaft (damage inside the valve cover verified this. I suspect he must have bought a top end complete and changed the head as well as the cam shaft, as the head was from a later model, and the spare barrel I now had matched the head, originally came with the replacement top end).

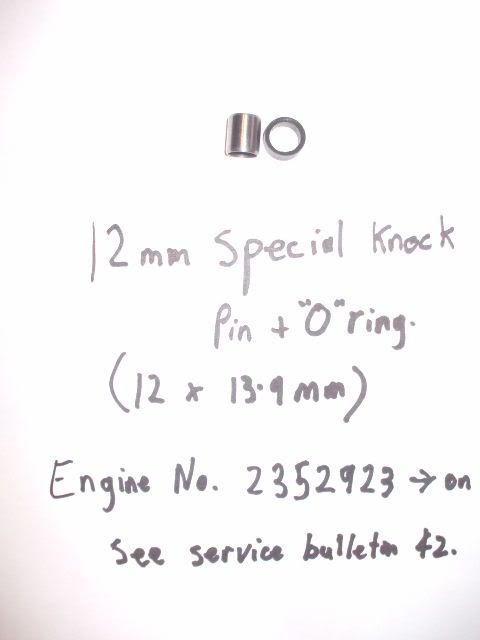

The barrel with the good fins was from a K3 or later model as it had drillings at the top around some of the studs for the extra dowel (or knock pins, as Honda called them) pins, with their little rubber bands, in the fight against oil leaking from the head gasket. See Honda Service bulletin No. 42 for details of this upgrade.

This new barrel had been left out in the weather and was corroded an the top deck, but the top of the sleeves were good , so I deemed it serviceable and had it bored to suit a K2 Wiseco 836 kit.

But wait! The K3 barrel is 1mm taller from base to top than the K2 barrel, Perhaps I could have the deck machined to get rid of the areas of corrosion. I suspect Honda changed the piston height when they changed the barrel height since the compression ratio remained constant. I had ordered a K@ Wiseco kit.This came with the earlier style head gasket, so I suspected This piston height was consistent withe earlier engine. What this meant was I could shave the block by 1mm. First I check valve clearance - install a pair of valves with weak springs and dry fitted the head without a gasket and measured the valve stroke , which was 5mm before hitting the piston, which was at TDC. Valve angle is roughly 45

0, so half 5mm = 2.5 mm clearance, less 1mm if deck shaved + 1mm for gasket = plenty of room to shave the deck

Hold on - the Knock pins sit in the K3+ barrel will need to be shortened 1mm

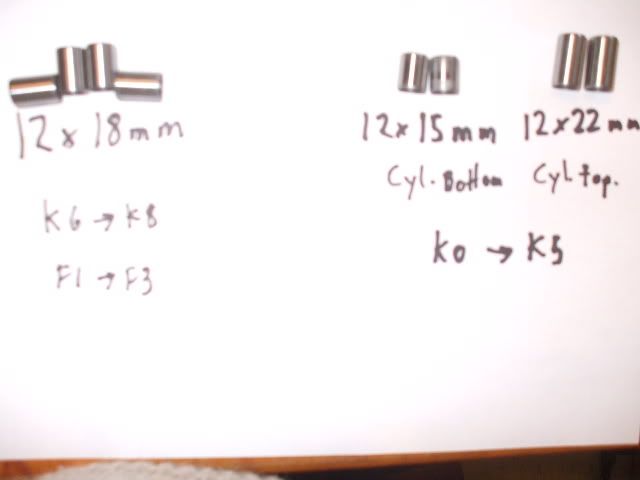

tTe dowels that go in the front corners of the top and bottom of the barrel need attention. Turns out up to K5 had 15mm upper dowels, 22mm lowers, K5 and later 18mm all round. This was the type I now had.

Not finished yet... The top deck had two 1mm deep recess for O rings where the oil is pumped up into the head Barrel had to be taken to a different man than he who bored if for milling.

Only thing left is to modify the 836 Wiseco gasket to take the knock pins.

All ready for assembly. Until next time...