Couple things to report tonight...

DSS stuff showed up!

New rims, spokes, tubes, genuine points, side cover emblems, oil filters, air filter, mirrors, etc.

Honestly the quality of these reproduction rims is mediocre. There are definitely some flaws in the chrome and feel more cheaply made than OEM but I guess that's what I get for half the price. I will still run them but I will think about one day re-chroming my stock bits.

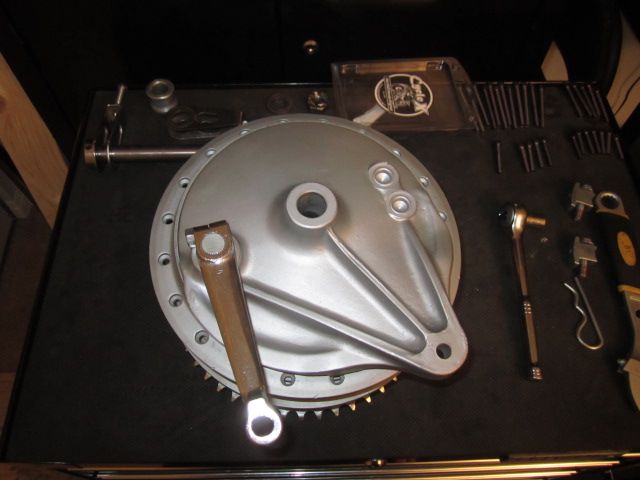

Since cycle x sent my near rear drum shoes I decided to tear into this bad boy again.

Comes apart real easy when it's all clean and greased.

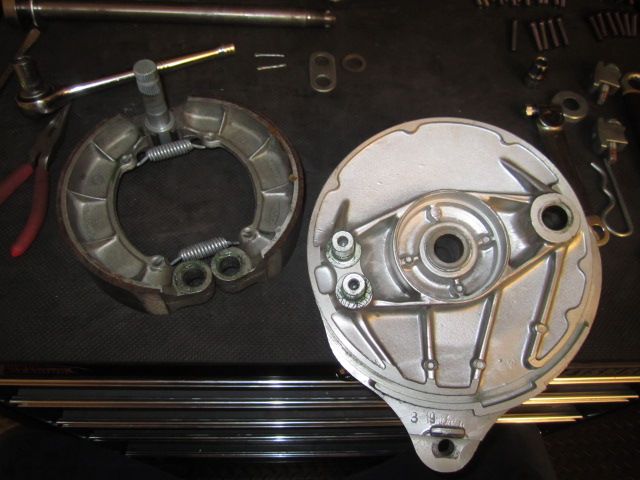

Fresh pads.

The new pads really don't have much more material than the old ones. Peace of mind I suppose.

After some wrestling I got it on.

Back on the bike. Still need to decide if I want to run the stock sprocket cover or not.

On to the clutch. Cycle X kit came with new HD frictions so why not put em in, right?

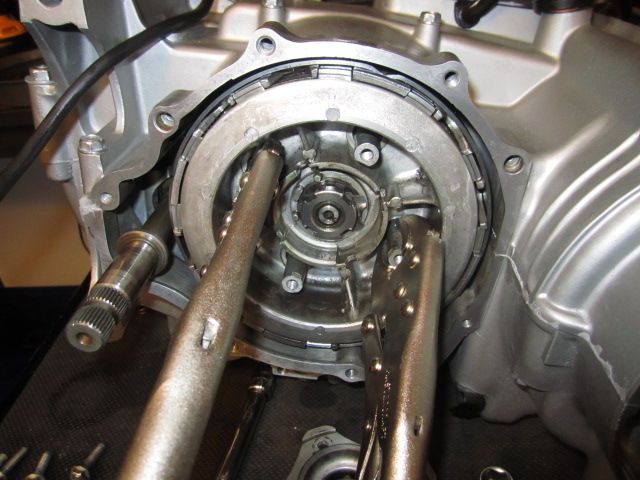

Bearing plate pops out easy enough.

Springs follow.

Bend the tab back on the lock washer and then a hammer and punch to turn the nut off. NO this is NOT reverse threaded. I really should get the proper tool for this. Hammer and punch is pretty hack.

This pulls out after the bearing plate is removed to reveal...

The old stack up... just pops out.

My model has 7 frictions and 6 steels. My kit came with 8 frictions for some reason?

All the old stuff. My steels are actually slightly burnt. Not horrible but if I have clutch issues down the road then maybe worth deglazing or replacing.

New frictions have been soaking in 10w40 for a couple days now.

Stack them in alternating friction then steel... starting and ending with a friction plate. Also note the angle of the "cuts" in the friction material will sling oil out of the clutch pack. (The clutch spins clockwise right?)

Stackin up my new clutches. I was having a hell of a time tying to get everything to line up in the basket so I pulled it all out and did it outside the bike.

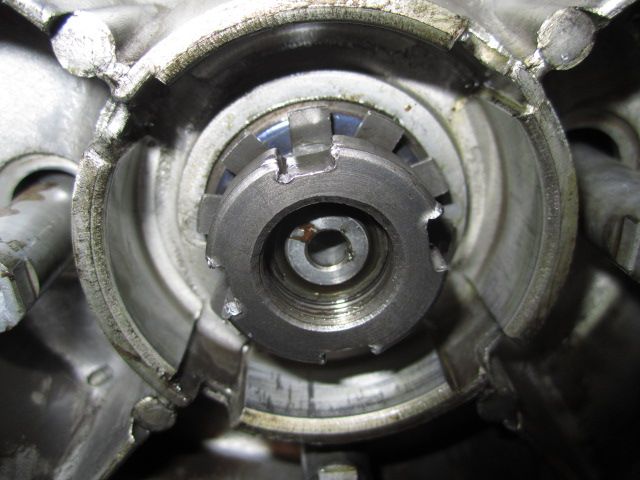

This is what it looks like when your front plate is NOT engaged correctly in the back plate (don't know the actual names). This is how guys break their front bearing plate ears.

Pull the front plate, spin it 90 degrees to the next hole and drop it back in. Now you can see the front plate is resting directly on the first friction. This is what you want.

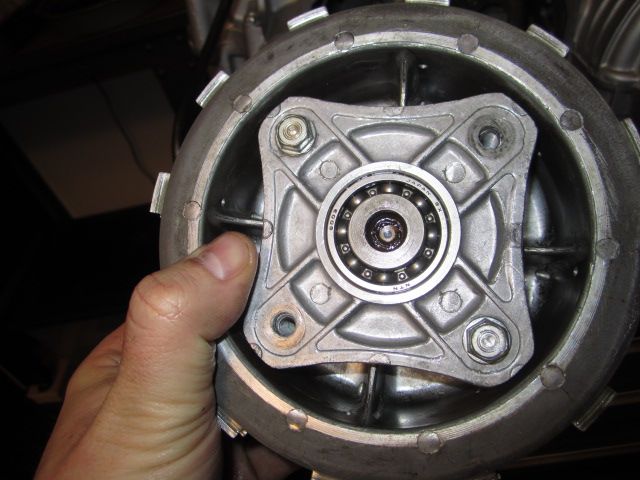

I held it all together but just loosely doing up the screws. This way you can use the bearing plate to pull the back plate towards you and keep the rear splines engaged. I lined up all the tabs on the frictions and slipped it all in the bike as one unit.

Make sure that the first friction is still resting directly on the back of the front plate.

The vise grips hold the back plate up tight so the splines don't disengage. I found out it's not about pushing the front plate back into the splines ... you have to pull on the legs of the back plate to get it to come forward and engage the splines.

Gently thread in the bolts trying not to push that back plate back. Tighten them in sequence to pull it in evenly.

All tightened up with a dab of blue loctite on each... If front plate is not engaged in the back plate splines then you WILL break the bearing support ears. Proper engagement allows the ears to be tightened down directly onto the rear plate posts. If the splines are not engaged you will be tightening the ears down but there will be a space between the ears and the posts of the back plate. This will bend the ears down until they snap.

I've read a lot about people breaking their bearing supports and this is definitely the reason why. I took my clutch apart and put it back together many times to figure this out so hopefully it makes some sense to someone. lol

IW