You can buy just the connector blocks (the plastic part) and clean up the connectors (the brass parts). I have rehabilitated the entire harness of more than one CB750. Takes about two weeks working through the weekends and almost every evening. Manually cleaned EVERY connector:

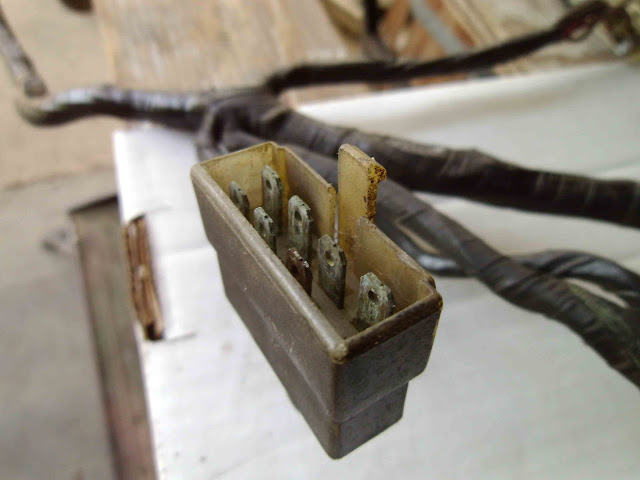

Some of the worst connectors looked like this:

Vintage connections makes a tool that helps getting connectors apart:

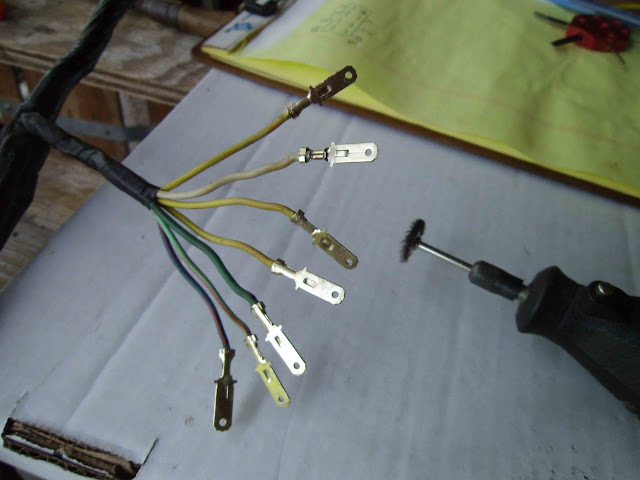

Keep a notepad handy for those multi connector blocks:

YUCK!

A Dremel with a wire wheel is a POWERFUL tool!

Steel wool does a good job of cleaning rattlecan overspray off the wire insulation that some goob PO got all over EVERYTHING:

Nice!

Don't forget to bend the retaining tabs back into place:

Voila'! (as opposed to "Viola" which everyone knows is a musical instrument)

I then gave all the newly cleaned contacts a shot of tuner cleaner/lubricant:

http://www.radioshack.com/search/index.jsp?kwCatId=&kw=tuner%20cleaner&origkw=tuner+cleaner&sr=1For those connectors that were too far gone were replaced with new connectors from vintage connections:

http://vintageconnections.com/Be sure to use the smaller bullet connectors to match the stock ones (there are two sizes), and splurge for the crimp tool. Looks like a factory crimp when done properly.

Purple Power (or "That Purple Stuff") does a bang up job of removing paint from plastic without damaging the plastic. Use gloves when removing parts from solution and wash parts thoroughly. It does not appear to harm plastic, but it's a little rough on the skin.

The female connectors (both bullet and spade) are more difficult to clean (insert favorite chauvanist remark here) but the same principles apply. For the female spades I used the dremel w/wire wheel for the outer part of the connector (just to remove any oxidation that might promote more oxidation) and then used a narrow strip of tin with a narrow strip of 320grit sandpaper folded over it to clean the inside of the spade connection. A pinch with the pliers prior to reassembly to assure a good, tight connection finishes the spade connectors (don't forget the locking tab on these too). The male bullets clean up the same as the male spades, while the female bullets require either a small diameter wire bottle brush (.177 cal bore brush is a popular choice) or an assortment of small diameter diamond stones for the Dremel (my choice). Again, a little pinch with the pliers to assure a tight connection, a little shot of tuner cleaner/lubricant, and, if you did everything right, you're good for another 30 years.

While I was at it I pulled apart the switches and cleaned them too. Here is the rear brake switch at the rear brake foot pedal:

Before:

After:

If you don't want to tackle the whole harness at once (quite daunting) then start with the primary circuits starting at the fuse box. Clean all the fuse holder connectors and harness connections to the fuse box. Then inspect/clean all the problem connectors, especially those connections to the alternator. I did this more targeted approach (as opposed to the whole harness) with my daily driver a couple years ago after it started blowing the main fuse. Still trouble free after this form of maintenance. This process WILL try your patience.

Oh yeah, DISCONNECT THE BATTERY!