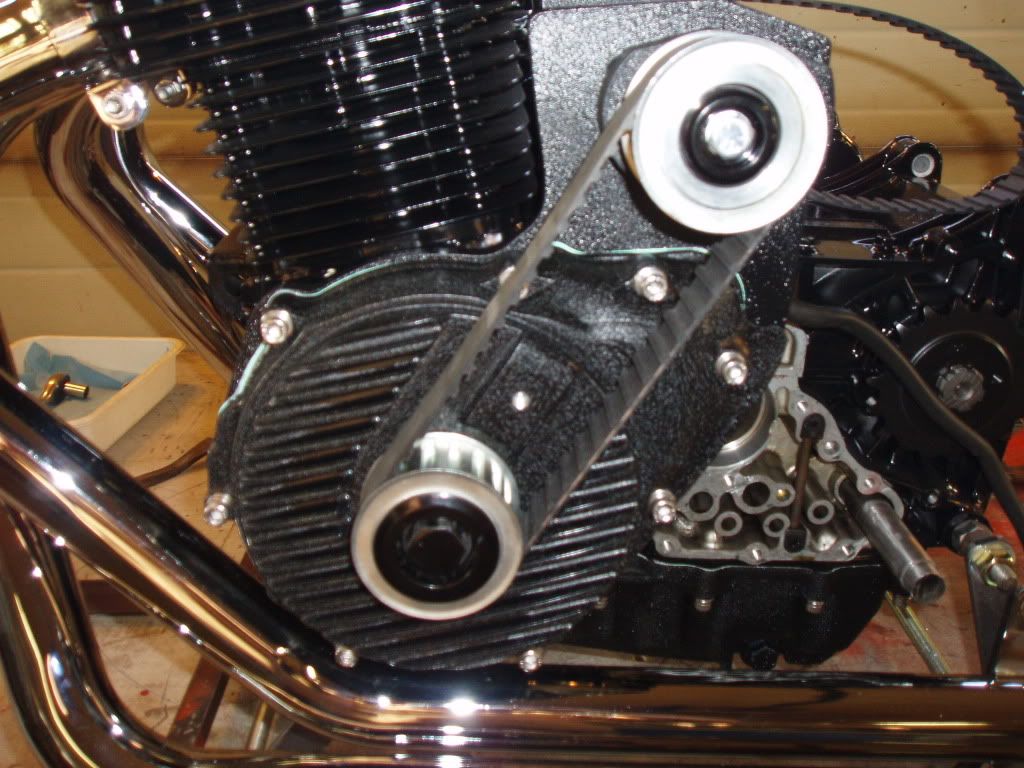

Mercuno; I used one of them little 35 amp Nippon Denso internally regulated alternators on my bike. I run it just under crankshaft speed. It charges even at a slow idle. There is only two wires used to make it work...one big wire directly to the battery and one small sensing wire to the ignition "on." These alternators can rotate CW or CCW...just the fan part matters if the alternator is under a hood.

My bike is supercharged and I use the alternator as a tensioner for the blower belt. You can quite easily do something similar sans the blower stuff. I removed the stock rotor and machined all the unneeded stuff from same.

I made a place for a seal and step/with key on the old rotor;

I used timing belt pulleys...you could use v-belts:

Made a different cover to hold the seal and have the pulley on the outside of the cover (away from oil):

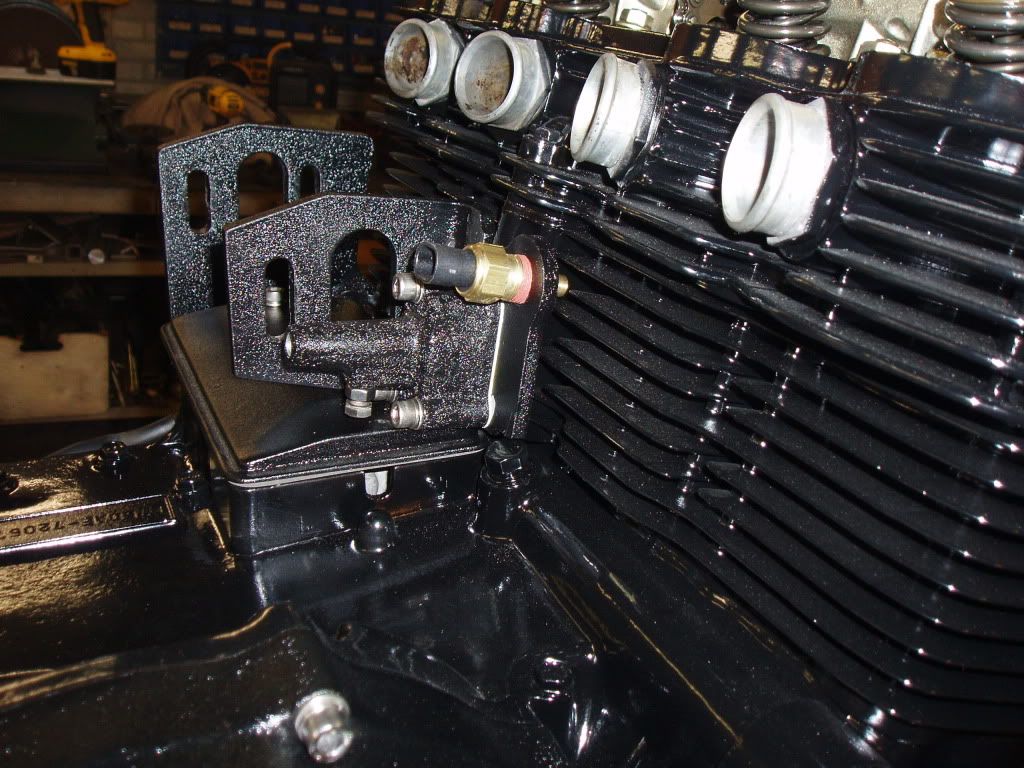

Here is the new cover in place with the pulley. I have a 3/8" thick aluminum bracket sandwiched between the engine and the cover. You need two gaskets of course. You have to make a longer starter idler shaft as well

I have used two brackets for a jackshaft going to the blower drive which you won't need to do of course...just showing you the reasoning behind the sandwiched 3/8" aluminum. You could easily make a similar sandwiched aluminum bracket to hold an alternator.

You have to seal the big rotor bolt. The crankshaft is hollow and oil will get past the threads.

Hope this gives you another way to "skin the cat?"