-oil system

Oil feed to the turbo is fed via an 18" -3AN braided line. The oil is sourced from the service port on the right side of the motor. An adapter bought from Ebay is installed and provides a 1/8 NPT port. A 1/8 NPT tee from ATP turbo was acquired; 1/8 NPT male to two female 1/8 NPT. One is for the feed and one can be used for a temp and or pressure gauge. I happen to have Nordskog digital temp and pressure gauges that have 1/8 NPT sensors that I can temporary use later to gather oil temp/pressure data with. The feed line fastens to a M10x1.25 to -3AN adapter that threads into the turbo's oil feed. The specs listed for the turbo on the Ebay ad noted that the oil feed threads where 1/8 NPT, but I found out after buying the adapter that they where the M10x1.25.

When the oil feed was expected to be 1/8 NPT I bought an adapter with an oil restrictor for journal bearing turbos. The restrictor necks down the oil feed to around ~0.060-0.065 or so (depending where bought) for journal bearing turbos and larger Garrett GT ball bearing turbos and ~0.035-0.030" for the smaller ball bearing turbos. The idea is that it restricts the max oil pressure to prevent oil from leaking pass the center cartridge's seals into the compressor or turbine. Weather or not this is needed on a CB motor I'm not sure. I don't know if the max oil pressure would be great enough to get past the turbo's seal or not. I figured it would hurt to have one, other turbo bikes have used them to cure a smoking exhaust from oil pressures that forced pass their seals; as along as it doesn't starve the CHRA I'm fine with having it. It may even help maintain better oil pressure for the rest of the motor. In any case I was bummed when I found the threads were M10x1.25 and had to send the restrictor back. So I welded the end shut on the stainless steel M10x1.25 to -3 replacement and drilled a 1/16" (~0.063") hole to get my restrictor. I'll update if the turbo seizes up.

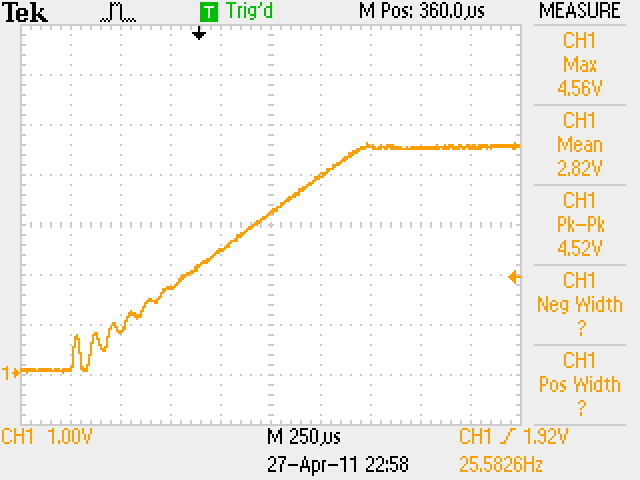

For the oil drain an accumulation chamber was added. The idea is to save the oil pump from having to "clamp down" on the entire oil drain and feed system all the way to the motor. By having the oil drain out of the turbo and into a chamber with a vent to the outside built in, the pump only draws vacuum from its "in" port to the accumulation chamber's drain. The vent on the chamber prevents the pump from "clamping down" any further up the line, and should allow the pump to operate with less power consumption from the CB's fragile generator. I have yet to measure the current draw before and after plugging the vent hole to see if it works as intended or not, I'll update when I have data. There's also a tiny K&N filter on the end of the vent to prevent contamination into the oil system.

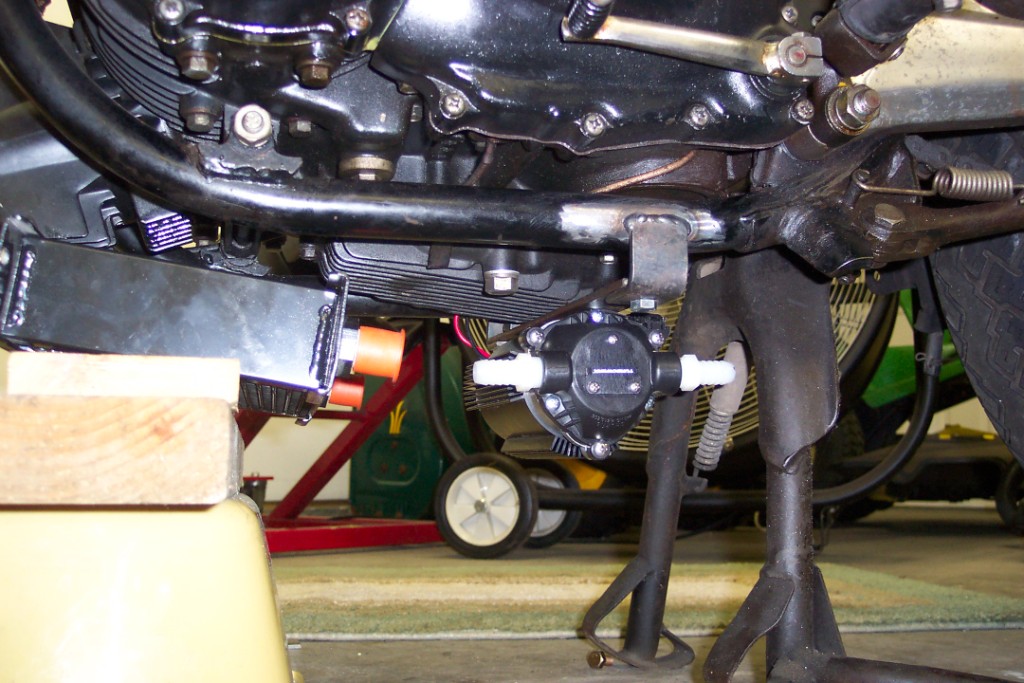

The pump that is being used is a Turbowerx unit. The pump is a re-badged Surflo pump with what I assume to be an oil and temperature safe diaphragm. Haven't heard much regarding the pump, but Surflo pumps are of quality which gives peace of mind. The pump has a heat sink secured on the outside of the pump body for extra cooling capacity. Weldon also makes some nice pumps and was also considered, but are a bit more expensive. The pump was secured under the belly of the bike with a simple bracket welded to the frame (see pic). Since the pic, two worm drive clamps were added around the pump to help secure it. I was apprehensive at first about adding the pump and cooler under the bike, but after all was said and done there is plenty of clearance. I would say the hardware hangs about and inch or two lower than the stock exhaust. The clearance with the pump and cooler is actually the same as my father's HD Fat Boy, and probably higher than some sport bike fairings.

The oil cooler is a 12"x8"x2" (off the top of my head) and of unknown brand (made it Canada) that I picked up on Ebay for cheap. It was mounted in a car but never used. It was decided to mount it underneath to save room in front. This gives the option of adding a intercooler above the header further down the road if and when higher boost pressures come into play. The cooler has a simple bracket welded to the frame that keeps it secure. An aluminum air scoop is tack welded and the seam sealed up with Rite Stuff. The cooler's outer metal frame was a bit too thin to lay a solid bead of aluminum to seal it up, the caulk/gasket maker did a fine job. I'm interested to see how well the ram air through the scoop will work. I plan to take some back to back oil temp readings with the cooler as is and with it stuffed with a few rags to block the air flow; I'll update when I have data, which might not be till next riding season cuz its getting cold quick.

The oil is fed into the turbo, drains out of the turbo and into the accumulation chamber, is pumped out of the chamber, through the pump and into the cooler, out of the cooler and back to the motor via the #1 cylinder's intake tappet cover. The hose that is used is a Aeroquip oil safe hose in 1/2 I.D.

oil accumulation chamber

oil scavenge pump

oil cooler

oil cooler w/scoop

feed line, oil cooler, oil accumulation chamber