So I wanted to make this walk through .. this is based on advice that I was given by Hondaman but I couldn't find a walkthrough for it anywhere and stumbled my way through it. Thought maybe I could make it easier on some other new comers. .

PROBLEM : I had low oil pressure at idle .. I also had a TERRIBLE time shifting into neutral if the bike was stopped .. this was worse as the bike would heat up. My oil pressure would go down and my shifting would get harder and harder.. ..

I did three things to resolve these issues ..

1. Drilled the clutch basket to improve oil flow across the clutch.

2. Replaced the o-rings on the oil pump which had flattened and shrunk down.

3. Replaced the o-ring on the countershaft oiler.

here's some info that I gathered while doing so..

------

The first thing I did was to drill additional oil holes in the clutch basket .. This is in Hondaman's tech articles .. found here ..

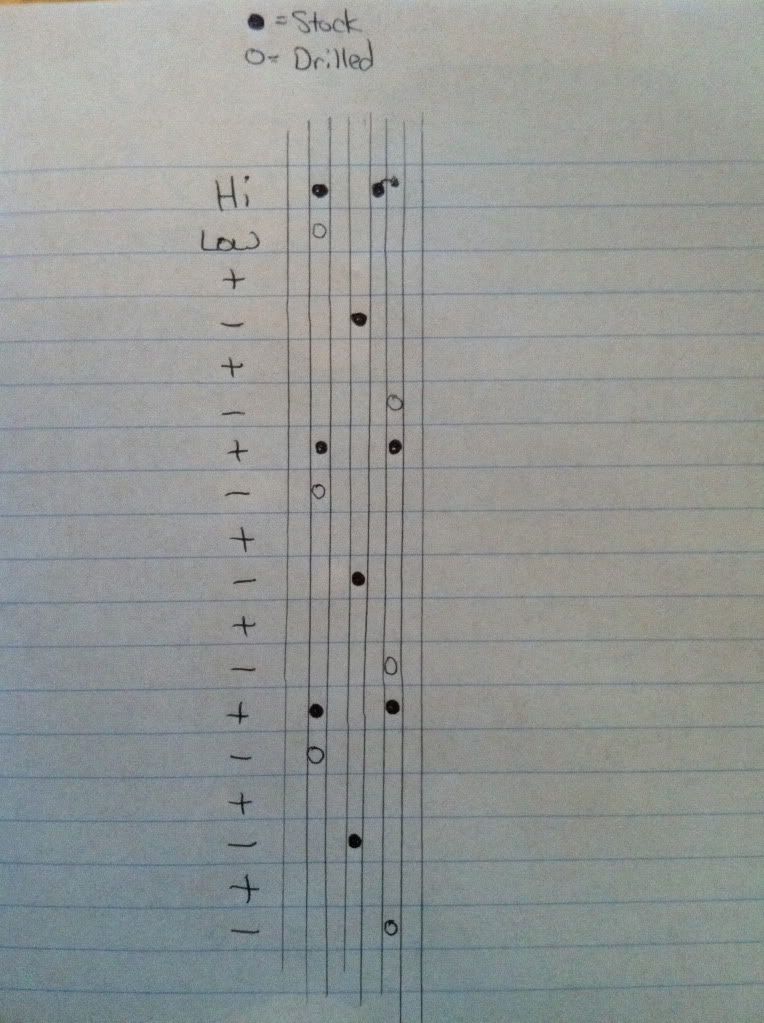

http://www.sohc4.net/index.php?q=node/278Here is a picture of it and another picture that shows the approx** pattern that I used when i drilled it.. This is just hand drawn and is only meant to be a guide.

After this was done there was a noticeable improvement in the shifting of my bike. Much less of that feeling like the bike always wanted to take off, even when the clutch was pulled in all the way.

--------------------

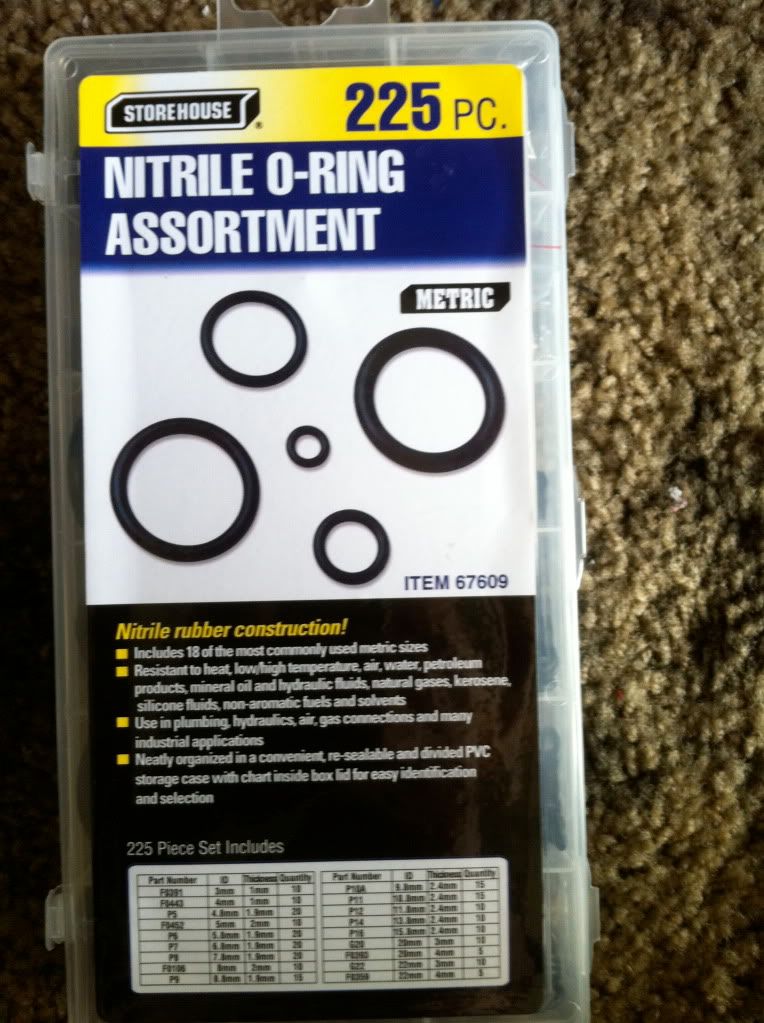

all the o-rings you need for the rest of the project can be found in this pack sold at harbor freight.

2. The o-rings on the oil pump..

I've heard many people talk about their oil pressure .. it seems common that most show about 10psi for every 1k of rpms .. I too had pressure like this .. My oil pressure now holds pretty steady .. Even at low idle its still 65lbs or so... this is what I did..

- removed 4-1 exhaust ..

- removed oil pan held by 10mm bolts.

- cleaned debris from oil pan and replaced gasket , set aside.

- removed oil pump with 4 bolts that held it in place .

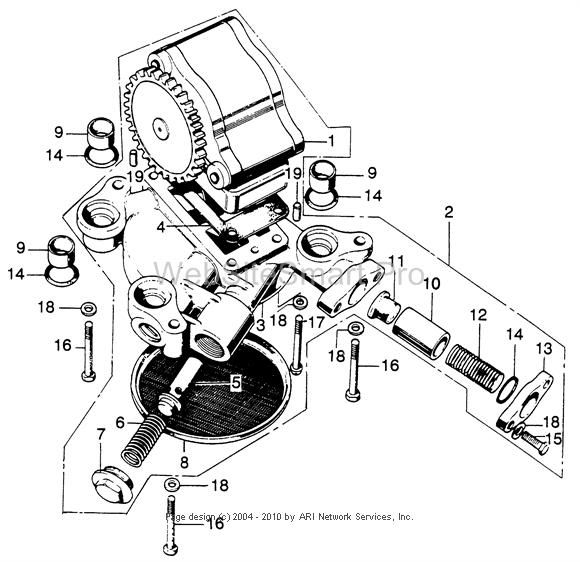

- ensure all the little steel sleeves for the oil passages stay in place.. In this picture the sleeves are #9 .. don't loose em .. they're loose in the pump.

- replace o-rings #14 .. 3 of them. .. they are 15mmx2.5mm ..

here is a picture of the old and new o-rings together.. It's hard to see but the new one was almost twice as thick..

After you install the new o-rings the assembly is just the reverse of what we've done already. One thing to note is that it's recommended that you prime the oil pump before you reinstall it. Do do this put it in a tub of fresh oil and spin the gear until all the air is out.

-------------------------

3. Countershaft oiler O-ring ..

This one is huge to me .. I'm sure this is the biggest reason I can NOW shift into neutral while stopped at a stop light

<cheers>To get this done I needed one o-ring from the kit purchased. I also needed a dremel and an impact screw driver .. I'm pretty sure from what I read that most people will have a hard time with the screws involved in this..

- remove shift lever.

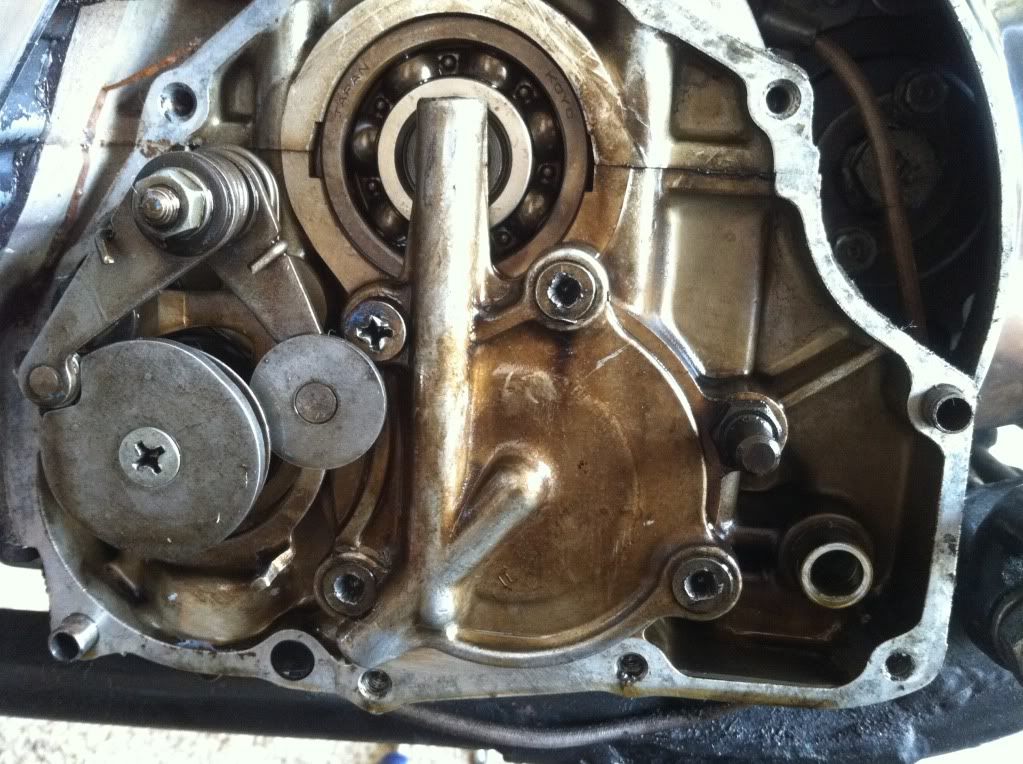

- remove trans cover.

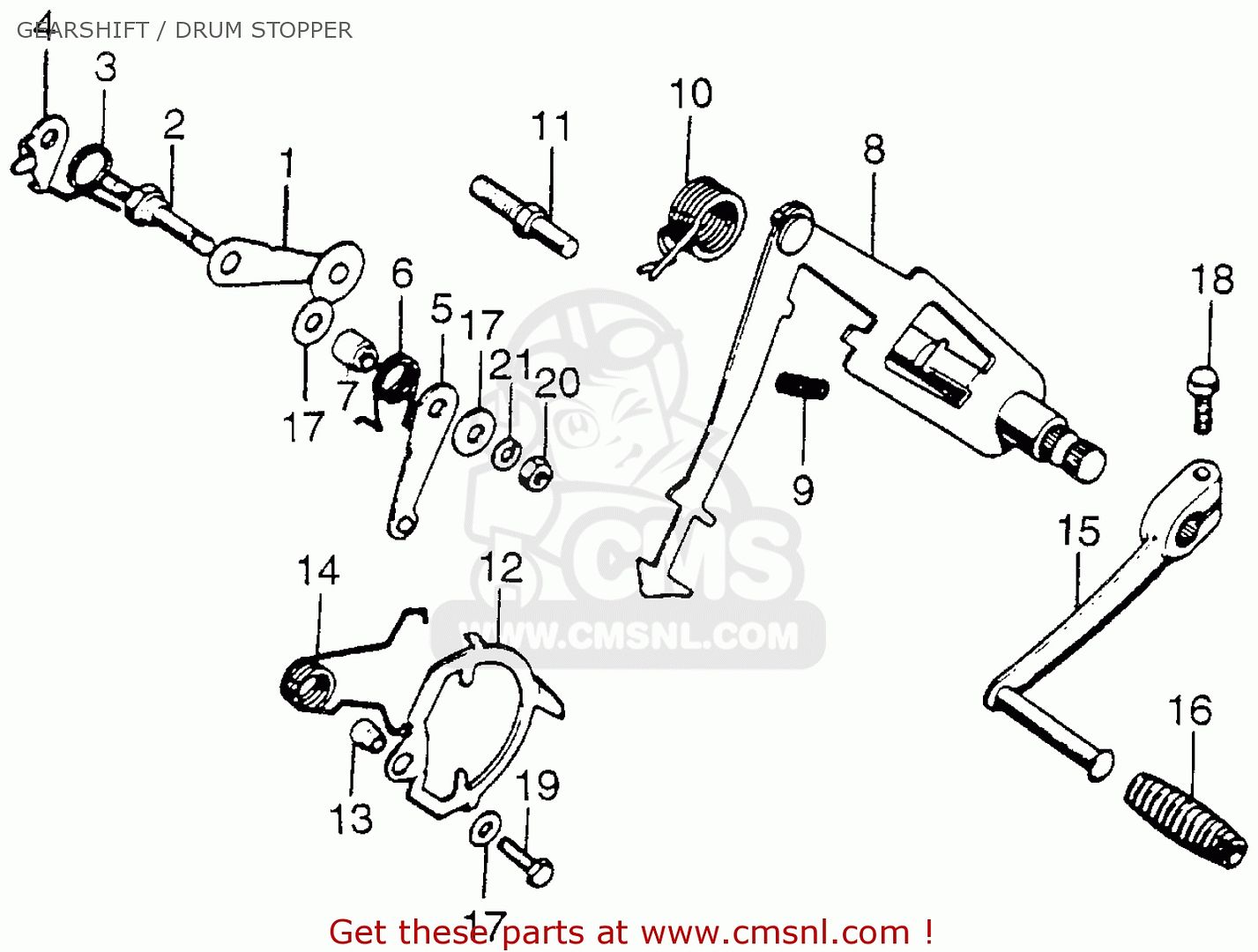

- Carefully remove linkage and note it's assembly ..

this is where things go bad ..

the 4 screws that hold the countershaft oiler are uh .. difficult.. I tried a large screwdriver with a crescent wrench on it, did not try this for long. Could tell immediately that was not going to work so I bought an impact screw driver. The 2nd hit of the impact properly finished the points inside the screw.. See picture.

dont panic .. thats what i told myself.

so at this point i got out the dremel and cut slots into each of the 3 mangled screws ..

I then used the wide flat head bit from the impact screw driver and gave it a couple more whacks ..

ps. this is a good time to tell you not to buy the harbor freight impact driver for $4.99 .. it sucks .. at least go to the auto part store and buy their $12.99 one or better yet sears for $39.99. The tips in the harbor freight one just fell right apart.

yay success ! !

so this is the o-ring you need to replace .. I didn't spot it at first it's sooooo small .. mine was flat as hell and not sealing anything !

once you get that in there its just putting it back together and you're good to go, I used this time to also replace the seal for the shift lever as well.

Here is another diagram of that shift linage that you took out .. it was tricky to me getting it all back together .. this helped.

Hopefully this helps you to get a bike that runs better, smoother and for longer .. Enjoy.