Dave, I understand the concern, but was starting from scratch and preferred to use Honda rings. One successful racer in the US was pushing for me to find 0.8mm comp rings from a modern motocrosser but there weren't many 60mm options so these came partially by default. The pistons are low silicone content so will certainly grow in the bore. It wasn't an expensive venture so I'll see how it all holds up.

Jim, the pistons are Ross, around $100 ea. It took a lot of measuring and back & forth to get the right depth reliefs, height dome, etc. but my job card is available. I felt good when I found the Interceptor 60mm rings and bought a few sets. Then they were promptly unavailable.

The last time I checked nothing had changed, so sourcing different rings would be job one.

External lines

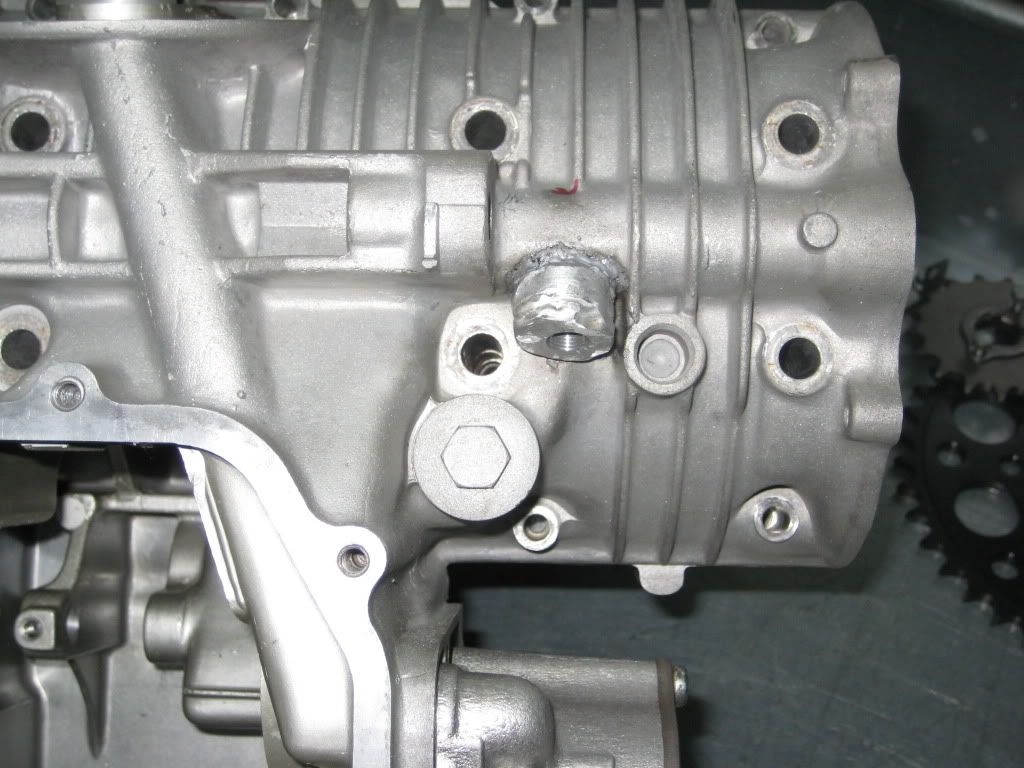

I wanted filtered oil for the cam but hate sourcing off the right gallery end, so finally welded up a boss, drilled & tapped for access right off the gallery in front of the oil pump. It's a safer location.

As a result of using a different countershaft and final sprocket position, plus a CB350 rear hub, sprocket alignment was a struggle. This frame is 78, the last year of production and it's obvious Honda's production tolerances were allowed to slide and things just didn't align. With the engine in the frame, I settled on a forktube in the crankshaft bore to measure back to the swingarm pivot and finally rear axle.

In the end the engine was offset 3.5mm

to the right in the frame, plus removed the 2mm rear sprocket washer and further machined 1.5mm from the outside of the new 520 rear sprockets to proper sprocket alignment. This leaves only the circlip locating the rear on the hub but I'm sure that's fine.

If that wasn't enough of a head scratcher, the engine was cocked in the frame and besides the offset, different shims were welded onto frame bosses, and one boss ground, just to align the c-shaft and the swingarm pivot. Honda driving sprockets "float" for good reason, it's very smart way to attach them.

In the front I have one thicker alloy engine mount on the left and also replaced the rear right original steel offset bracket with a flat alloy piece. Another year I will install bushings in the engine mounts and final ream to take the slop out of mounts. These frames need the engine for support.

Here's a shot of my attempt at stiffening the swingarm. The X shaped aluminum bracket is fastened at four points using splined shoulder bolts that hopefully add strength.....otherwise it's just a support for the ignition box & battery.

Did this first in the seventies, with only 6mm bolts and could see where the movement removed paint.

The chain roller is also visible, Simon & TG are right, those little rollers won't last, but I have another plan to make something better.