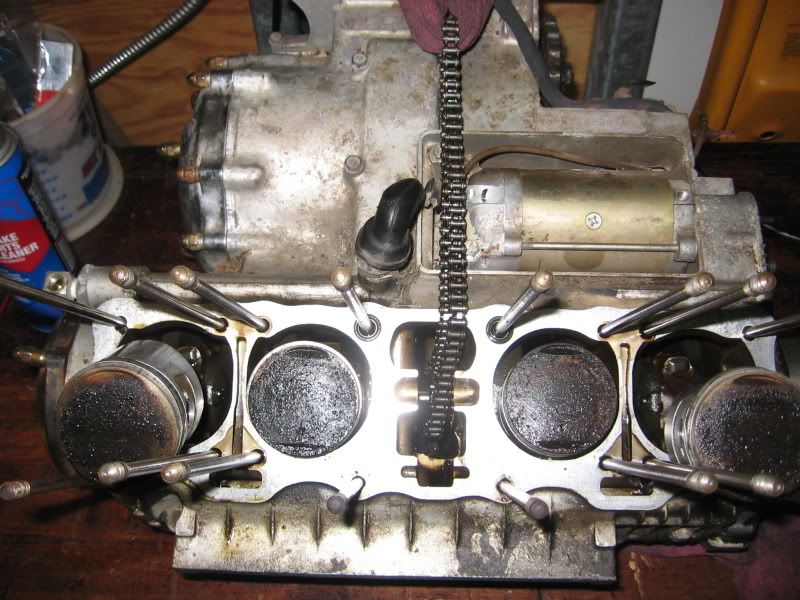

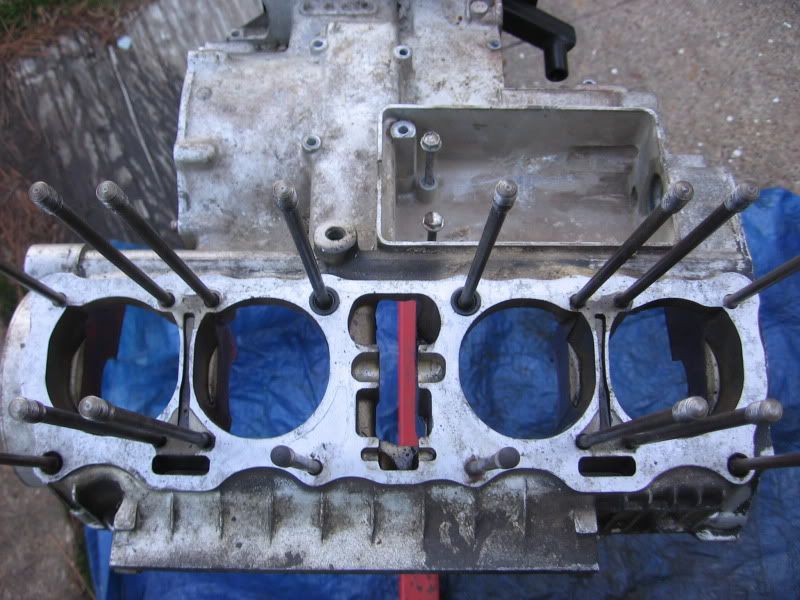

After I pulled the jugs off. It took a bit of banging with the rubber mallet to slowly work it up, but it came off without a hitch. I am a little worried to keep taking it apart since everything seems to look good. My intentions were to take it apart to see if I notice anything broken or wrong and to cleanup the block so I could paint it. At this point I think I might be able to clean the bottom end, but I am worried about painting it. I don't want to get anything inside of it. The top end I am certain I can finish taking apart and get it back together without a hitch.

After discussion with a couple of buddies I have decided to take it completely apart. Not know the history of the bike who knows if there is a spun bearing or something else catastrophic inside.

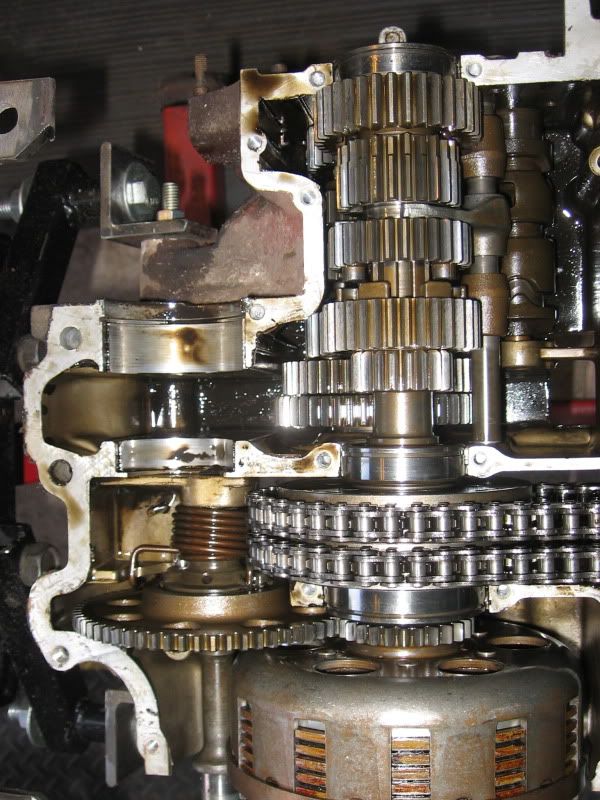

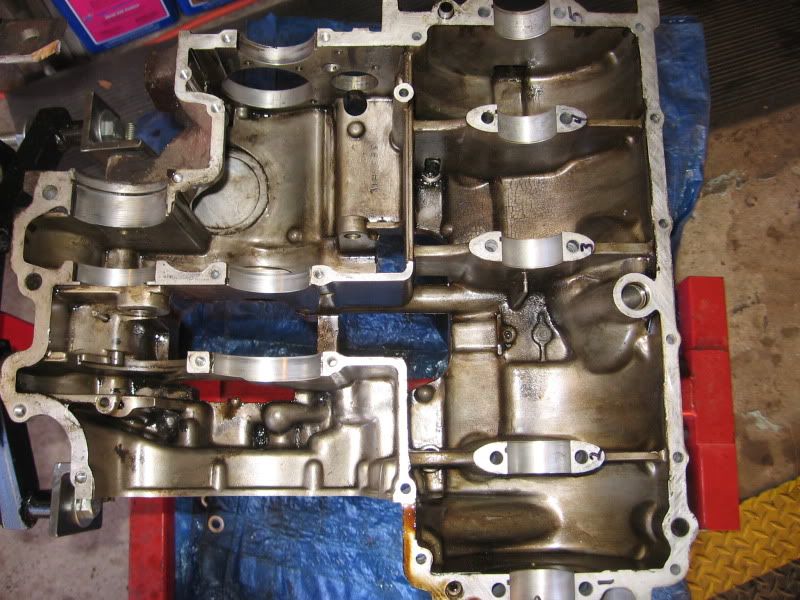

So I split the cases. Took a lot longer than it should have, but oh well. I had to make trip to the local Honda dealer for some tech advice. They have an older guy that works there that knows the CB's like the back of his hand. The manual just says to remove a particular bolt, but when I go to loosen it the crank shaft just spins. He gave me a trick to do, but I ended up not even removing the part since it was attached to the crank and the crank and attaching parts can come off as one unit after the case is split. The part I didn't remove is the thing sticking out of the engine to the lower right in the first pic.

[mg]http://img.photobucket.com/albums/v636/sharsh01/CB750/IMG_0047.jpg[/img]

And what the vast majority of a CB750 looks like in a tote

I got a fair amount accomplished today. Again I took it slow. My camera was giving me fits all day. I must have changed out the batteries three times. I guess my POS Canon point n shoot is giving up the ghost. Too bad the wife won't let me take use her nice camera. That is probably a good thing though.

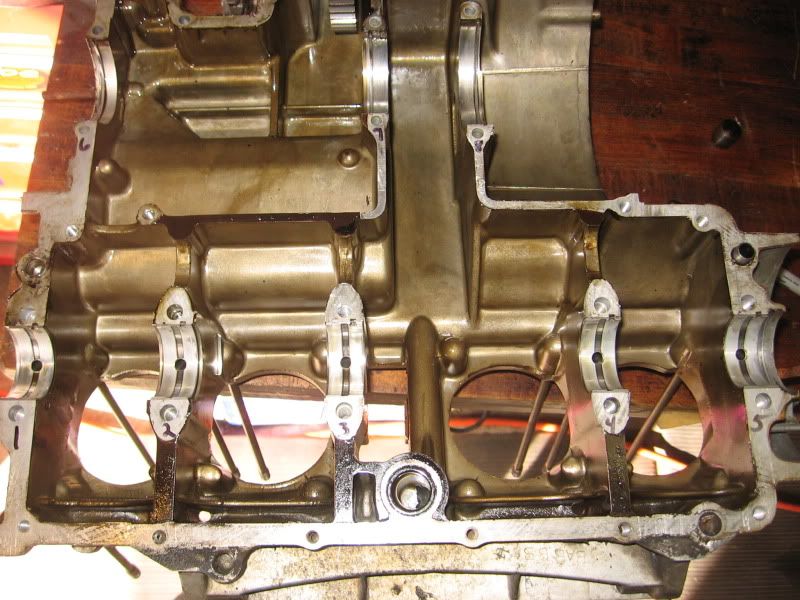

Numbered for posterity sake. I put each bearing in its own labeled baggie. Top half of case.

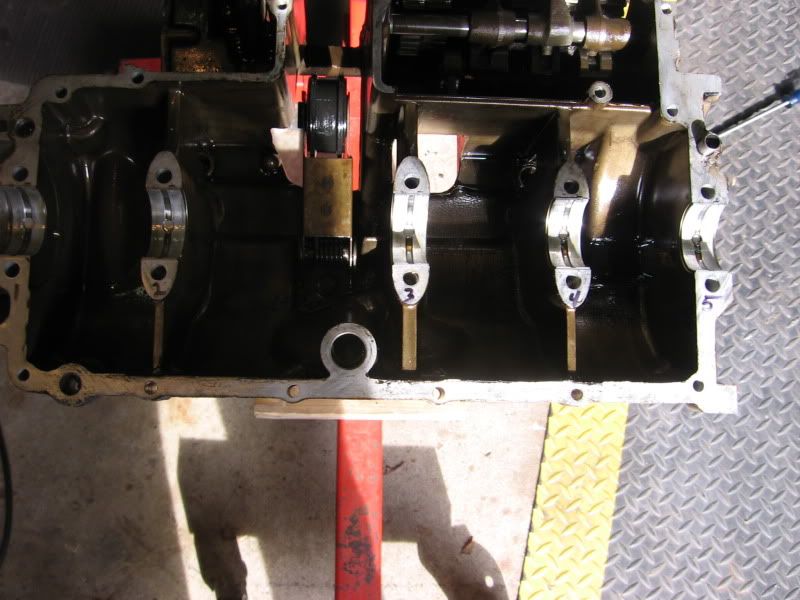

Bottom half of case.

With everything removed from the case except one bearing which you can't see. I have to get a puller for that.

Bottom of the engine...It is nasty with A LOT of caked in goo in the nooks and crannies.

All clean (well mostly)

Inside of lower case after cleaning

Oil pan inside and out...NASTY

All Clean

Now to the bad...I broke two studs today. The PO put in these stupid studs so that they could put on some bullet nuts on the outside of the engine. Well the studs are steel and the block is aluminum. I am going to go out on a limb and say they didn't use any antiseize or oil during installation. I was lucky enough to get all of the others out without too much of a problem. These two didn't want to budge so I have had them soaking in PB blaster. Well I decided to try and get them out. I put on the vice grips and started to gently wiggle them back and forth. They appeared to be moving just a tiny bit with every back and forth motion so I kept going...slowly. Then the inevitable snap. I drilled out one of them and tried to use the easy out, but it wasn't budging. Not wanting to snap the easy out I tried some more PB and heat. Nope, nada, nothing. So they are sitting in some more PB. Luckily they aren't in a sealed area. There is one broken stud in each case half and they both go to the cover for the points.

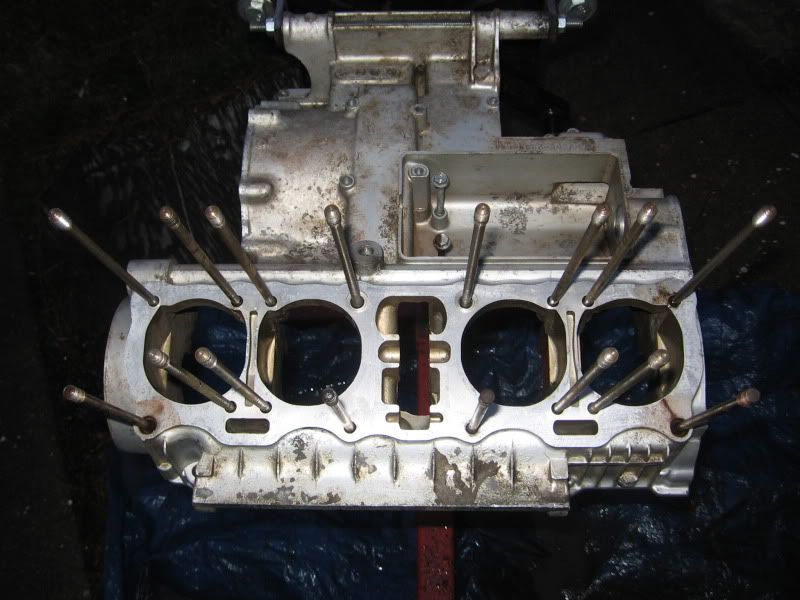

Cleaned up the top half. Not as a big of a difference as the bottom, but it is definitely cleaner. My gasket and oil seal kit came today as well. I am a little worried since I see a whole lot of gaskets and seals that I don't remember removing. However, since I haven't taken the head apart I am hoping they go in there. I also didn't take apart the oil pump so I bet some of them go there as well.

Before cleaning

After cleaning

New gaskets/seals