I made progress on several fronts...

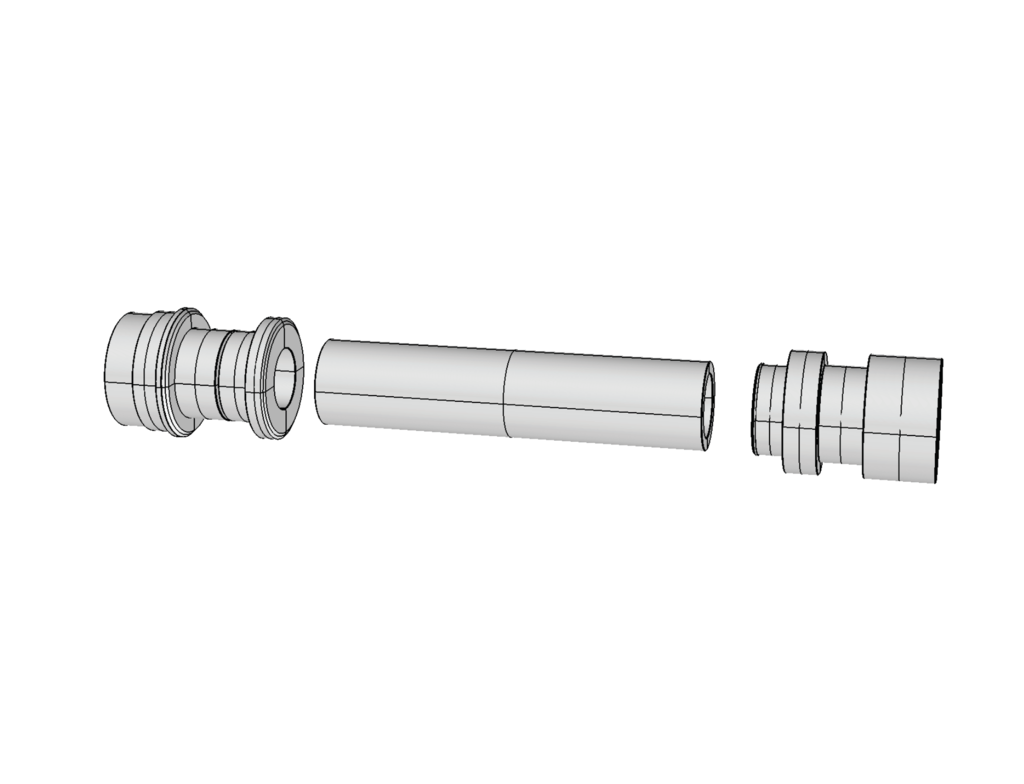

I made spacers for back wheel. Wheel I am using is made for 25mm axle... I had to make spacers for 20mm axle...

Also I changed wheel bearings from 6205 to 6304(25mm ID to 20mm ID).

Wheel is perfectly centered in swingarm. Tolerance +/- 0.1mm

Because I wanted to save time I bought brake that goes with this wheel(KTM adv 1190 R)

But I didn't think about how it will look. That brake holder will never go with my bike. It doesn't look good.

So the solution was to design and make holder...

This one is better looking

... Also I had my forks disassembled, straightened, assembled(note to everybody: there is a big chance that you are buying forks from crashed bike. Always check if forks are bent, and usually they are

.

Fender holders are cut. There is not a trace of them anymore