The "Evolution" is officially back underway (about damn time)! The engine is on the stand, and in the process of closing up the holes in preparation for cleaning/degreasing prior to disassembly, the following efforts to obviously shed yet even more weight were discovered:

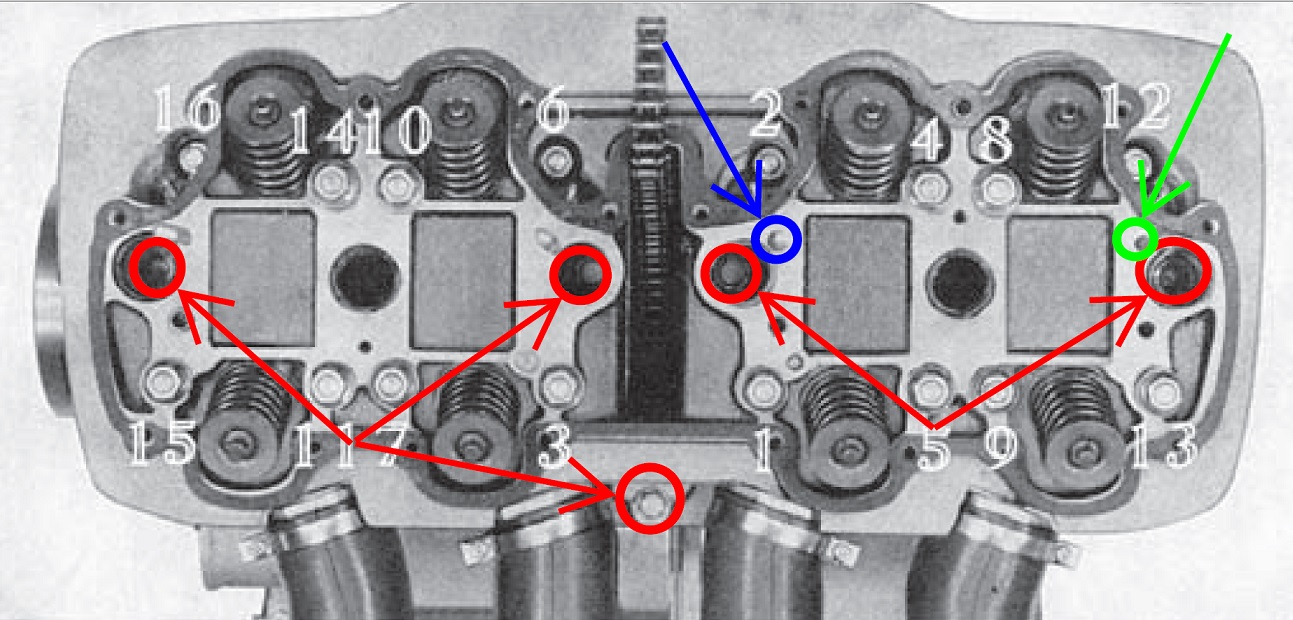

>The four 6mm x 35mm head bolts (circled in

red) as well as the 6mm x 90mm head bolt (also circled in

red and documented in a previous post) were omitted.

>Most of the washers from under the head nuts were omitted.

>One oil control orifice (circled in

blue) was omitted.

Fortunately, it appears as though there were not many miles ridden in this condition since the cam bearing surfaces appear to be in very good condition (no scoring or scratches on either the cam or bearing surfaces).

>One oil control o-ring was omitted (circled in

green). Not sure how much of a weight savings was gained by this particular omission...

>Two oil pan bolts were omitted as well.

These weight savings would have been progressive, in that the oil leaks were so pervasive that the farther you rode the more weight that would have been shed (in the form of lost oil). The oil leaks were further supplemented by the placement of the cam bearing cap studs. Now we

all know that these studs belong across the front side of each cam bearing location since these holes are bottomless and require thread sealer to prevent "weeping" oil. Well... two of the studs were placed at the far right bearing cap, while the other two studs were placed at the far left bearing cap without any hint of thread sealer to boot. The two center bearing caps were held in place by bolts on both sides of the bearing cap, also sans any trace of thread sealer. Not to mention the "musical chairs" that was played with the bearing caps since the bearing cap markings did not match the corresponding markings on the cam towers at their installed location. At least the caps

can be arranged correctly since the cap markings do correspond to markings on the cradles (when properly oriented).

I was hoping not to have to tear too far into the motor, but it looks like it will go as far as pulling the cylinders (minimum) for piston/ring inspection and or replacement, smoothing of the head gasket surfaces, new cam chain tensioner, valve lapping, along with gaskets and seals.

Also figuring on:

>Oiling system maintenance:

http://forums.sohc4.net/index.php?topic=78643.0;topicseen>New shocks

>New brakes

>New tires/tubes/rim strips

>New clutch plates

>Working my "mojo" on the wiring harness:

http://forums.sohc4.net/index.php?topic=137351.msg1549191#msg1549191>New chain/sprockets/battery/filters/bulbs (as necessary)

>Electronic ignition

>More polishing and painting

Picking up the party right where it left off!

Some people just should not be permitted access to hand tools. Best case scenario here would be the rider would be stranded on the road somewhere. Worst case scenario the condition of this hack job of a motorcycle could have turned out very badly for anyone attempting to ride it in it's current state.